Safety Note

01

• This manual elaborates on installation and safety use information for PV power gener-

ating modules (hereinafter referred to as module) of LONGi Solar Technology Co., Ltd.

(hereinafter referred to as LONGi). Please abide by all safety precautions in this guide

and local regulations.

• Installation of modules requires professional skills and knowledge and is to be carried

out by qualified personnel. Please read this manual carefully before installing and using

this module. Installation personnel shall get familiar with mechanical and electrical

requirements of this system. Please keep this manual properly as reference for future

maintenance or upkeep or for sales and treatment of modules.

• If you have any doubts, please contact LONGi customer service personnel for further

interpretation.

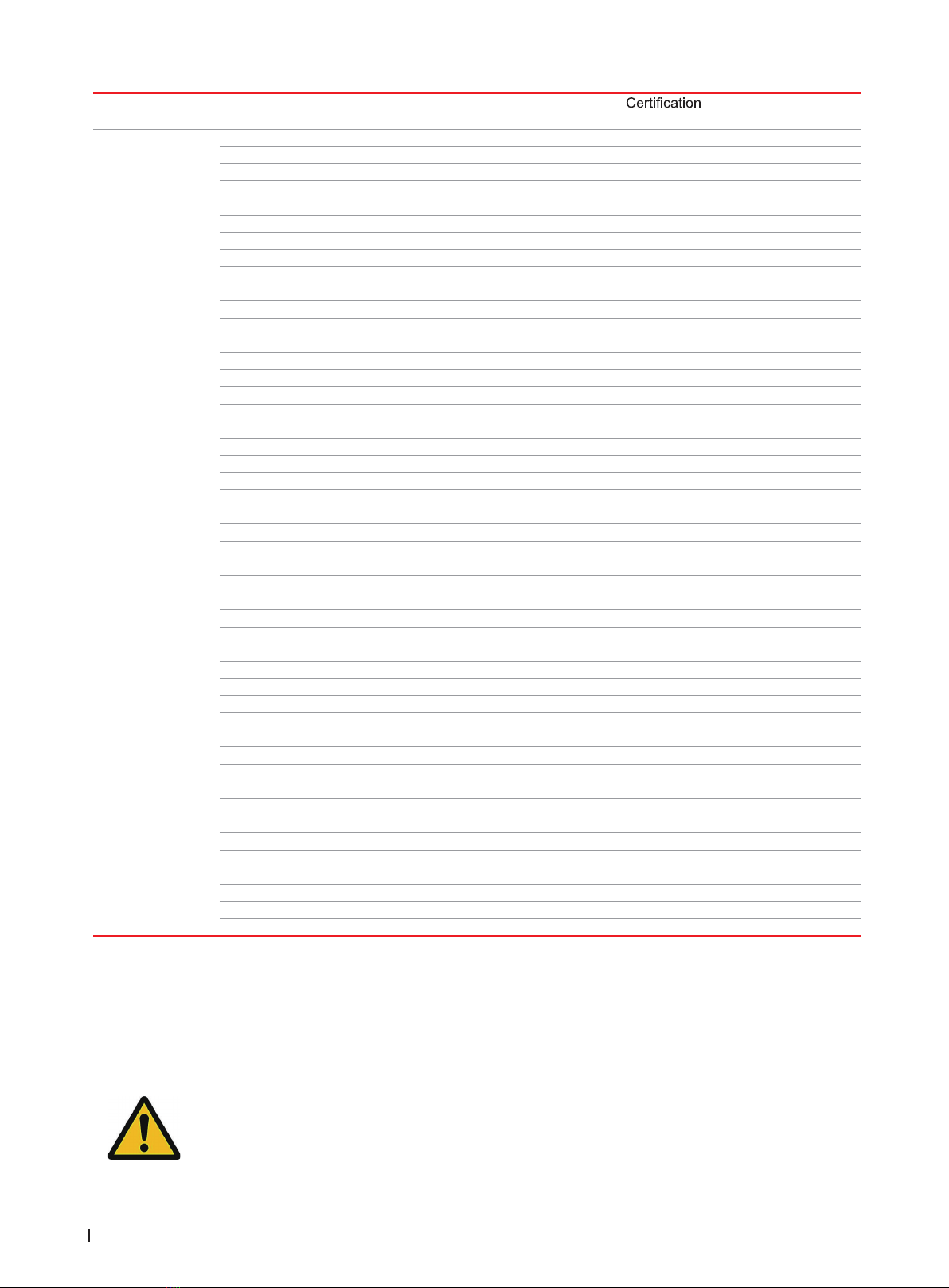

Applicable Module Type Status

Module

Structure

Monofacial

Module

LR6-60-***M LR6-72-***M IEC、UL single glass

LR6-60BK-***M LR6-72BK-***M IEC、UL single glass

LR6-60HV-***M LR6-72HV-***M IEC、UL single glass

LR6-60PB-***M LR6-72PB-***M IEC、UL single glass

LR6-60PE-***M LR6-72PE-***M IEC、UL single glass

LR6-60PH-***M LR6-72PH-***M IEC、UL single glass

LR6-60MP-***M LR6-72MP-***M IEC single glass

LR6-60MPH-***M LR6-72MPH-***M IEC single glass

LR6-60HPH-***M LR6-72HPH-***M IEC、UL single glass

LR6-60HPH-***MC LR6-72HPH-***MC IEC、UL single glass

LR6-60HPB-***M / IEC、UL single glass

LR6-60OPH-***M LR6-72OPH-***M IEC single glass

LR6-60DG-***M LR6-72DG-***M IEC、UL double glass

LR6-60PD-***M LR6-72PD-***M IEC、UL double glass

LR6-60HPD-***M LR6-72HPD-***M IEC、UL double glass

LR6-60HIH-***M LR6-72HIH-***M IEC、UL single glass

LR6-60HIB-***M / IEC、UL single glass

LR4-50HPH-***M / IEC、UL single glass

LR4-60HPH-***M LR4-72HPH-***M IEC、UL single glass

LR4-60HPB-***M / IEC、UL single glass

LR4-60HIH-***M LR4-72HIH-***M IEC、UL single glass

LR4-60HIB-***M / IEC、UL single glass

LR4-66HPH-***M / IEC、UL single glass

LR4-66HP-***M / IEC、UL single glass

LR4-66HIH-***M / IEC、UL single glass

LR5-54HPH-***M / IEC、UL single glass

LR5-54HPB-***M / IEC、UL single glass

LR5-54HIH-***M / IEC、UL single glass

LR5-54HIB-***M / IEC、UL single glass

LR5-54HNB-***M / IEC、UL single glass

LR5-54HTH-***M /IEC、UL single glass

LR5-54HTB-***M /IEC、UL single glass

LR5-66HPH-***M LR5-72HPH-***M IEC、UL single glass

LR5-66HIH-***M LR5-72HIH-***M IEC、UL single glass

/ LR5-72HTH-***M IEC、UL single glass

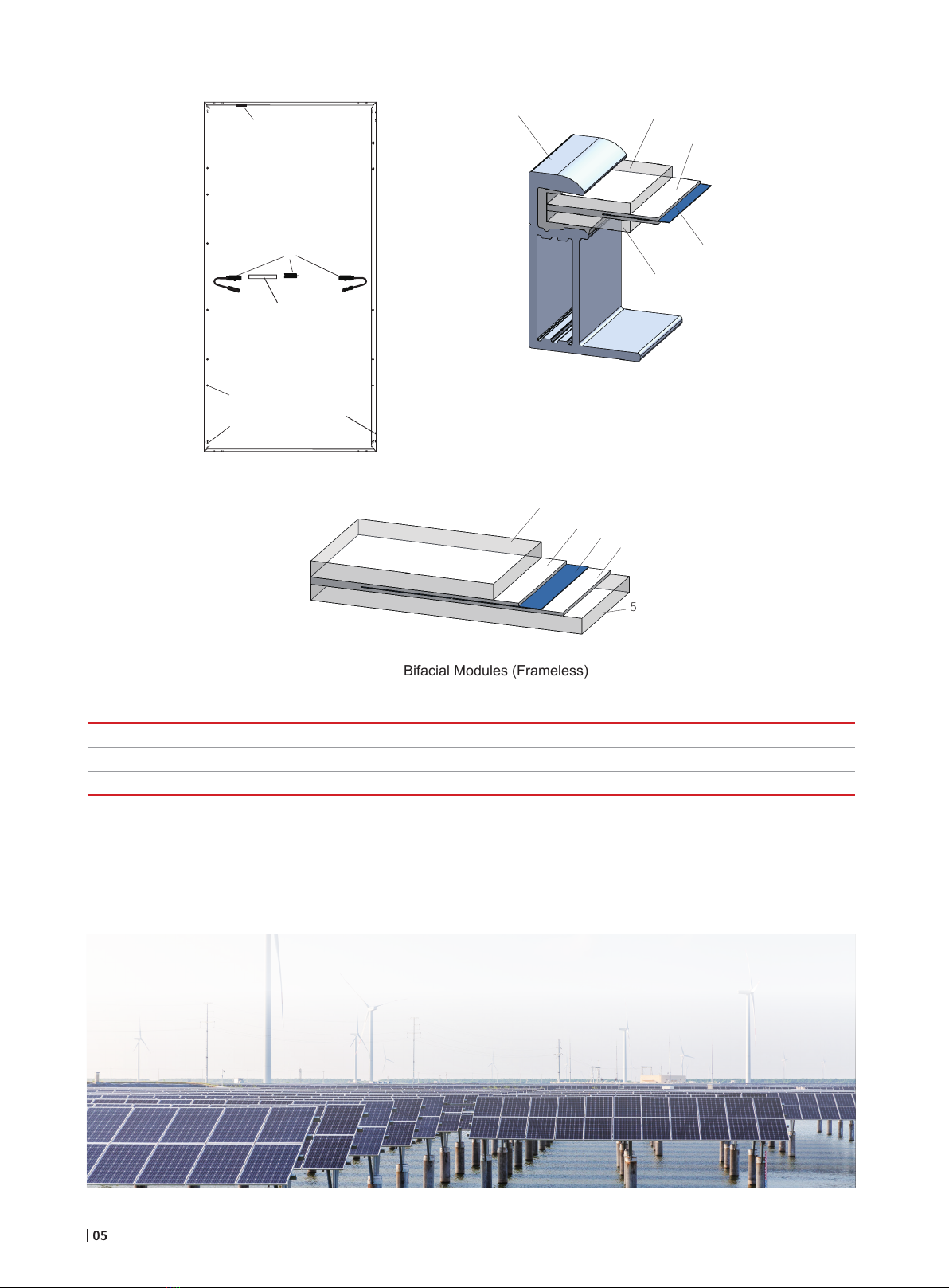

Bifacial

Module

LR6-60BP-***M LR6-72BP-***M IEC、UL double glass

LR6-60HBD-***M LR6-72HBD-***M IEC、UL double glass

LR6-60HBD-***MC LR6-72HBD-***MC IEC、UL double glass

/ LR6-78HBD-***M IEC、UL double glass

LR6-60OPD-***M LR6-72OPD-***M IEC double glass

LR6-60HIBD-***M LR6-72HIBD-***M IEC、UL double glass

LR4-60HBD-***M LR4-72HBD-***M IEC、UL double glass

LR4-60HIBD-***M LR4-72HIBD-***M IEC、UL double glass

LR5-66HBD-***M LR5-72HBD-***M IEC、UL double glass

LR5-66HIBD-***M LR5-72HIBD-***M IEC、UL double glass

/ LR5-72HND-***M IEC、UL double glass

/ LR5-72HTD-***M IEC、UL double glass