CONTENT

1

CONTENT

DEAR USER............................................................................................................................................................. 1

PREFACE................................................................................................................................................................. 1

CHAPTER I SAFETY INFORMATION.............................................................................................................. 1

1.1 SAFETY PROMPT................................................................................................................................. 2

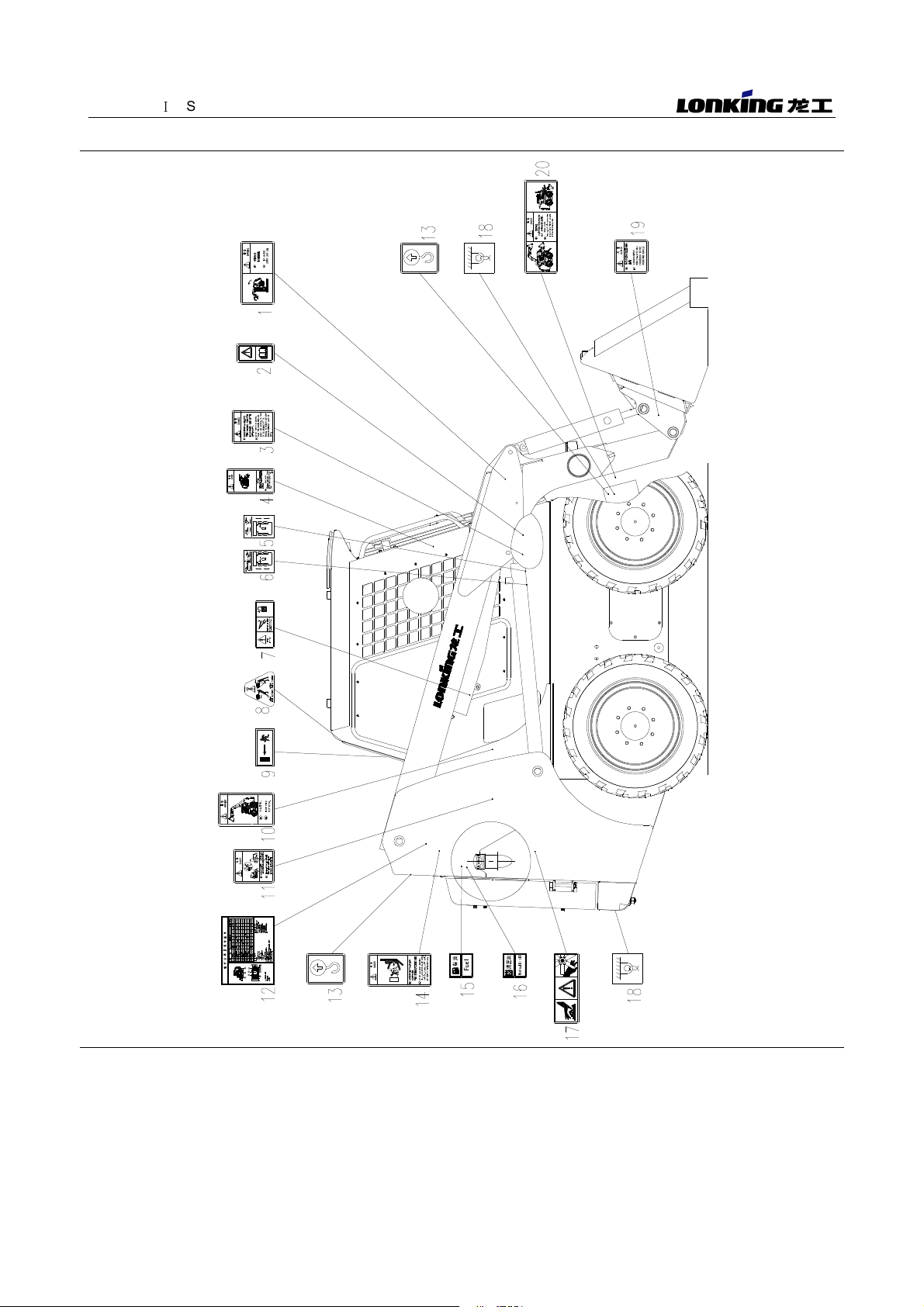

1.2 SAFETY LABEL..................................................................................................................................... 2

1. UNDERSTAND THE MEANING OF THE SAFETY SYMBOL.........................................................

1.4 DISTRIBUTING SCHEMATIC OF SAFETY AND ADDITIVE LABELS.......................................... 4

1.5 OTHER SAFETY INFORMATION..................................................................................................... 14

CHAPTER II PRODUCT INFORMATION....................................................................................................... 22

2.1 MACHINE QUALIFICATION............................................................................................................... 2

2.2 MACHINE CONGIGURATION........................................................................................................... 2

2. PURPOSE............................................................................................................................................. 25

2.4 MACHINE SPECIFICATION............................................................................................................... 26

2.5 HYDRAULIC SYSTEM........................................................................................................................ 28

2.6 ELECTRICAL SYSTEM...................................................................................................................... 1

CHAPTER III MACHINE OPERATION........................................................................................................... 34

.1 CONTROL MACHENISM AND INSTRUMENT............................................................................... 5

.2 OPERATION OF SKID STEER LOADER........................................................................................ 6

. THE MAIN TECHNIC DATA OF COMMON USE............................................................................ 45

.4 FUEL,LUBRICANTS,GREASE AND THE COOLING WATER..................................................... 45

.5 INSECTION BEFORE OPERATION................................................................................................. 46

.6 STARTING AND PARKING................................................................................................................ 48

.7 OPERATION CONTROL.................................................................................................................... 49

CHAPTER IV MAINTENANCE SECTION...................................................................................................... 54

4.1 MAINTENANCE AND PRECAUTIONS OF SKID LOADER.......................................................... 55

4.2 MAINTENANCE OF MAIN COMPONENTS.................................................................................... 57

4.

MAINTENANCE AND PRECAUTION OF EQUIPPED ACCUMULATOR SKID STEER

LOADER

........................................................................................................................................................ 57