8.4 IDENTIFICATION POINTS .......................................................................................................................................................................41

8.5 MANUFACTURER’S LABEL ...................................................................................................................................................................42

9. COMMISSIONING.......................................................................................................................................................................................43

9.1 CONNECTING THE BATTERY PLUG .................................................................................................................................................43

9.2 CHECKS AND ACTIONS BEFORE COMMISSIONING..................................................................................................................44

10. OPERATION................................................................................................................................................................................................45

10.1 OPTIMUM OPERATING CONDITIONS TO CONSERVE THE BATTERY CAPACITY ..........................................................45

10.1.1 RECOMMENDED SPEEDS ..................................................................................................................................................................45

10.1.2 DRIVING STYLE.....................................................................................................................................................................................45

10.1.3 SURFACE.................................................................................................................................................................................................45

10.2 BASIC INSTRUCTIONS FOR CORRECT USE OF THE CHARGING EQUIPMENT ..............................................................46

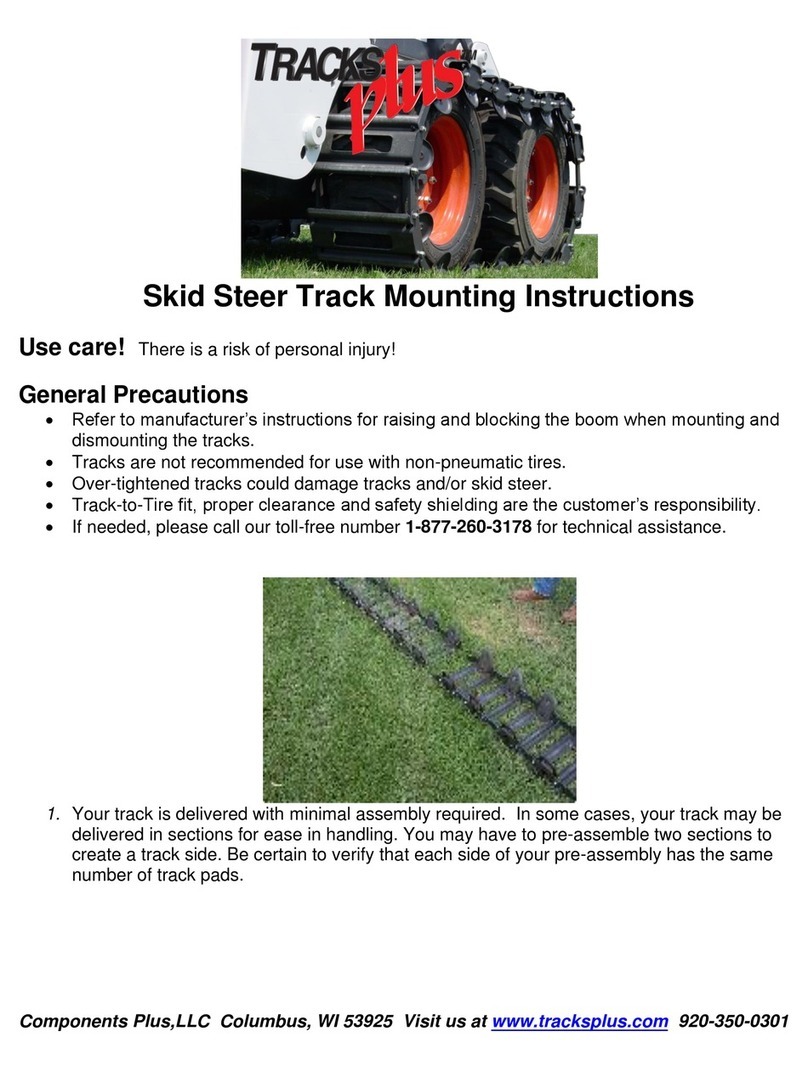

10.3 CHECKING THE CONDITION OF TRACKS.................................................................................................................................... 50

10.4 ENTERING AND EXITING THE LOADER ........................................................................................................................................ 50

10.5 SWITCHING ON THE IGNITION AND PUTTING THE LOADER INTO OPERATION ..........................................................51

10.6 CHANGING THE FLOW RATE OF HYDRAULIC OIL ..................................................................................................................52

10.7 WORK LIGHTS .........................................................................................................................................................................................52

10.8 ROAD LIGHTS .........................................................................................................................................................................................52

10.9 BEACON ...................................................................................................................................................................................................52

11. LOADER CONTROL – TRAVEL .............................................................................................................................................................53

12. CONTROLLING LOADER WITH A WORK ADD-ON .........................................................................................................................54

13. CONTROLLING LOADER WITH AN AUXILIARY HYDRAULIC DEVICE ..................................................................................... 55

14. REMOTE CONTROL MINIZ 400 ........................................................................................................................................................... 56

15. LIST OF OPTIONAL ATTACHMENTS ..................................................................................................................................................57

16. CLASSIFICATION OF ROCKS ............................................................................................................................................................... 58

16.1. CLASS 1.......................................................................................................................................................................................................58

16.2. CLASS 2....................................................................................................................................................................................................58

16.3. CLASS 3 ....................................................................................................................................................................................................58

16.4. CLASS 4 ....................................................................................................................................................................................................58

16.5. CLASS 5....................................................................................................................................................................................................59

16.6. CLASS 6....................................................................................................................................................................................................59

16.7. CLASS 7.....................................................................................................................................................................................................59

17. PREVENTIVE MAINTENANCE............................................................................................................................................................... 60

17.1 INSPECTION AND MAINTENANCE SCHEDULE ........................................................................................................................... 60

17.2 CORRELATION TABLES FOR OILS AND LUBRICATING GREASES.......................................................................................62

17.2.1 HYDRAULIC TANK................................................................................................................................................................................62

17.2.2 TRANSMISSION GEARS ....................................................................................................................................................................62

6.3.1 INSURANCE COVERAGE ON A CONSTRUCTION SITE...........................................................................................................24

6.3.2 ALTERATIONS AND MODIFICATIONS..........................................................................................................................................24

6.3.3 CHANGES TO THE DRIVER’S PROTECTIVE ROOF AND ROOF LOAD .............................................................................26

6.3.4 USE OF NON-ORIGINAL PARTS......................................................................................................................................................26

6.3.5 LOADER DEFECTS AND DAMAGE, INCORRECT USE OF SAFETY DEVICES .................................................................27

6.3.6 RISK TO STABILITY ..............................................................................................................................................................................27

6.3.7 MEDICAL DEVICES...............................................................................................................................................................................27

6.4 INSULATION TEST ..................................................................................................................................................................................28

6.5 SAFETY INSTRUCTIONS FOR HANDLING CONSUMABLES.....................................................................................................28

6.5.1 ALLOWABLE CONSUMABLES .........................................................................................................................................................28

6.5.2 OILS...........................................................................................................................................................................................................28

6.5.3 HYDRAULIC FLUID...............................................................................................................................................................................30

6.5.4 BATTERY ACID......................................................................................................................................................................................30

6.5.5 DISPOSAL OF CONSUMABLES........................................................................................................................................................31

6.6 EMISSIONS..................................................................................................................................................................................................31

6.6.1 BATTERY....................................................................................................................................................................................................31

6.7 FIRE SAFETY ...............................................................................................................................................................................................31

6.8 SAFETY RULES WHEN WORKING......................................................................................................................................................32

6.9 SAFETY RULES FOR MAINTENANCE ...............................................................................................................................................32

6.10 SECURITY RULES FOR TRAVELLING ON PUBLIC ROADS ......................................................................................................33

6.11 LOADING, CLAMPING WHEN LOADING..........................................................................................................................................33

6.12 IT IS PROHIBITED:...................................................................................................................................................................................34

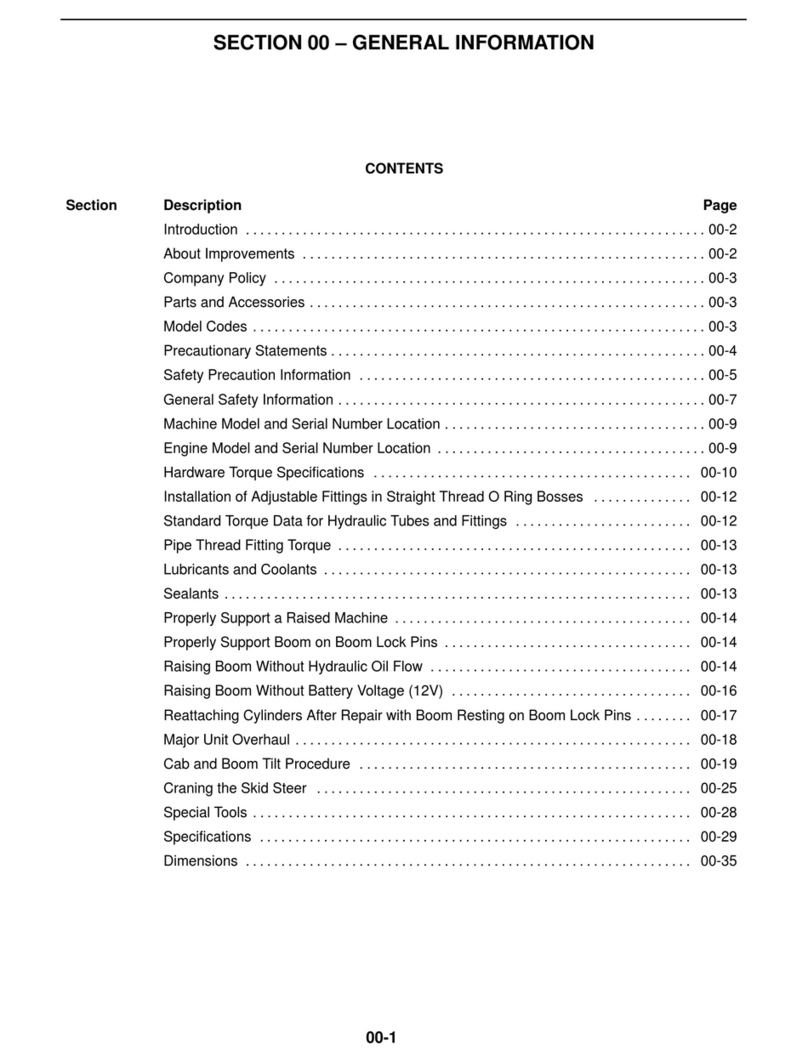

7. TECHNICAL DESCRIPTION......................................................................................................................................................................34

7.1 LAYOUT OF AGGREGATES ..................................................................................................................................................................35

7.2 ELECTRIC MOTOR ..................................................................................................................................................................................35

7.3 HYDRAULIC SYSTEM..............................................................................................................................................................................36

7.4 BRAKE SYSTEM.........................................................................................................................................................................................36

7.5 WORK DEVICE...........................................................................................................................................................................................36

7.6 CLAMPING ON ATTACHMENT............................................................................................................................................................36

7.6.1 THE "MINIZ" QUICK CLAMP................................................................................................................................................................36

7.7 ELECTRICAL INSTALLATIONS..............................................................................................................................................................37

7.8 TREADING PLATFORM........................................................................................................................................................................... 37

8. VIEWS ............................................................................................................................................................................................................38

8.1 OUTSIDE VIEW OF THE LOADER .......................................................................................................................................................38

8.2 OVERVIEW OF THE DRIVER’S PLACE .............................................................................................................................................39

8.3 OVERVIEW OF REMOTE CONTROL..................................................................................................................................................40