TM 11-5820-919-40-2

INTRODUCTION

This technical manual provides maintenance prints for Radio Set ANtPRC-104 (radio set). It is used in conjunction with the general instructions, maintenance information, and theory contained with the general instructions, maintenance information, and theory

contained in TM 11-5820-919-40-1. For parts ordering information refer to TM 11-5820-919-24P

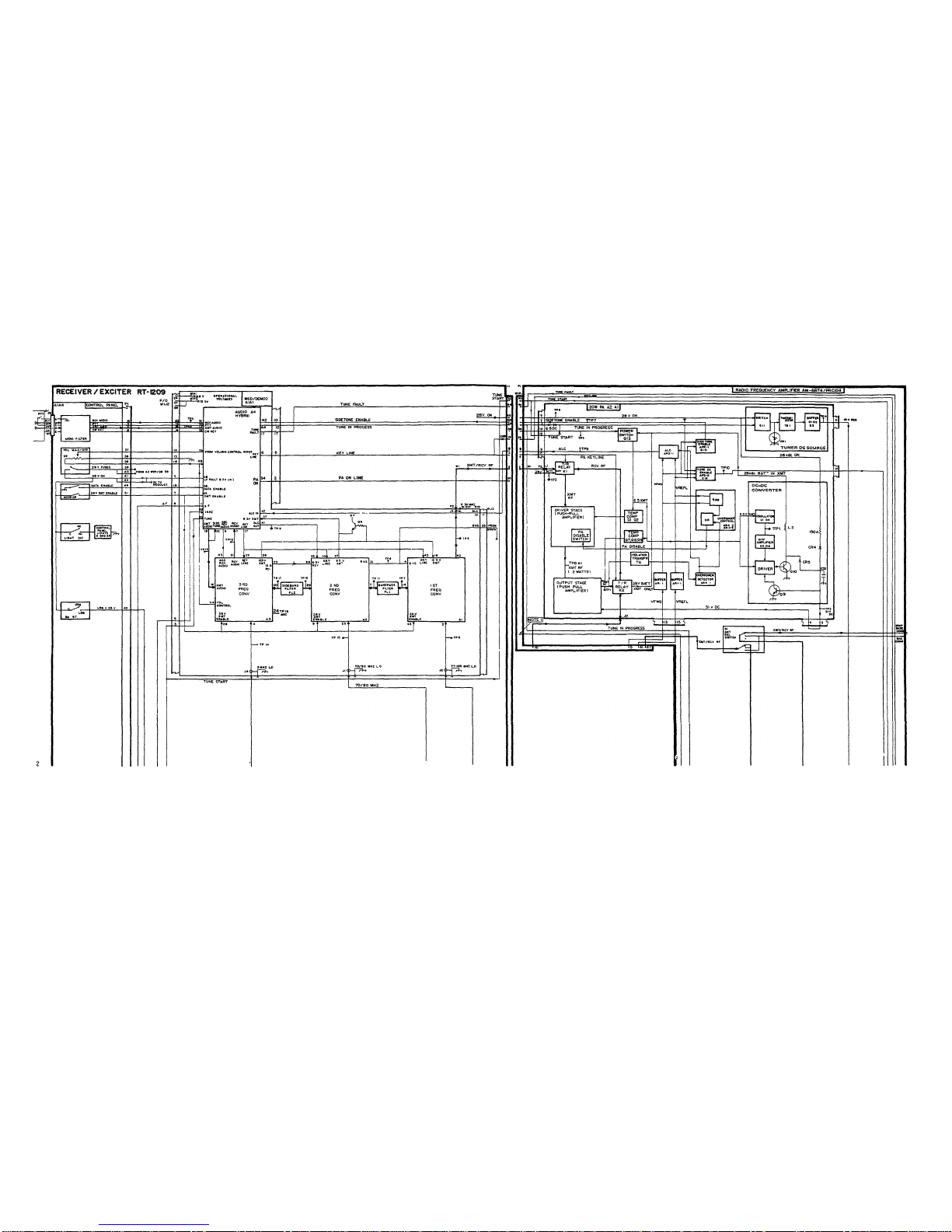

Maintenance prints are provided for the radio set; the receiver/exciter unit and its 5 modules; and the amplifier/coupler unit and its 2 modules. The maintenance prints radio set and the two units are the same as those contained in TM 11-5820-919-40-lo The

maintenance prints include schematics, power distribution; component location; test and alignment setup; performance test; and alignment procedures.

Schematic diagrams contain pertinent voltage and waveform reference data to assist in fault isolation and are used an conjunction with the performance test flowcharts.

Component location diagrams locate and list every replaceable component, and identify the location of test points and pins required to monitor voltages and waveforms on performance test flowcharts.

Test and alignment setup diagrams provide a list of test equipment, a list of special tools and materials, fabricated cables and fixtures, and initial connections for the test setup, They are used in conjunction with the performance test flowcharts. Module

performance tests may be performed more easily if the module is tested while inside the radio set, rather than extended via cables. Once a fault is indicated, the module should be removed from the radio set and connected via appropriate extender cables.

Performance test flowcharts provide performance test (heavy flow line) and troubleshoot mug procedures (light flow line) for fault isolating to a component or group of components. The flowcharts are supported by the reference information provided in the

other diagrams.

Alignment procedures are used in conjunction with the performance test flowcharts.

NOTE

Poor electrical connection due to dirty or bent connector plus may often be the cause of equipment malfunction or faulty test indication. All electrical connections should be double-checked before proceeding with test or fault isolation.

TECHNICAL CHARACTERISTICS

Characterlstlc Description

RADIO SET AN/PRC-104 (Radio Set)

Frequency Range 2.0000 to 29.9999 MHz in. 0.0001 MHz

(100 Hz) increments (280,000 possible

frequency settings)

Frequency Accuracy ±1 ppm for -51°F (-46°C) to +160°F (+71°C)

(±2 to 30 Hz of setting) from 2 to 30 MHz

respectively.

Operating Modes - Slngle sideband (selectable USB or LSB)

- Voice/cw (Morse or burst cw at 300 wpm)

- Data (FSK or DPSK up to 2400 bps) compatible

with 75 baud military teletype

- Receive only (inhibits transmit operation)

Audio Input Impedance 150 ohms, -56 dbm (voice) or, 6 mv. RMS.

and Level 600 ohms, 0 dbm (data) or, 77 v. RMS,

RP Output Power 20w (PEP), 0.25w (PEP) exciter output

RF Output Impedance 50-ohms, unbalanced. Output protected to

infinite VSWR due to antenna short or open.

Antenna Tuning Automatic to 1.5:1 VSWR (3 seconds

tuning time, typical)

Characteristic Description

Power Requirements 20.0 to 32.0 vdc with input at 3.5 amp

(24 vdc) for transmit (typical). 200 ma

for receive (typical).

Operating Temperature Range -51°F (-46°C) to +160°F (+71°C)

Environmental Meets applicable provisions of MIL-

STD-810B

Mean Time Between Failure (MTBF) 2500 hours (demonstrated per MIL-

STD-785)

Mean Time to Repair (MTTR) 15 minutes (module replacement)

Dimensions 12 1/2 x 10 1/2 x 2 5/8 (31.75 cm x

26.67 cm x 6.66 cm) D x U x H

Weight 14 pounds (6.36 Kg), including 4.8 AN

silver zinc battery (without

accessories)

RECEIVER

Sensitivity

SSB, Cal, FSK 0.7 v for 10 db SINAD (-110 dbm

voice, -70 dbm data)

Selectivity 2.5 kHz Bandwidth at -3 db

SSB, CW, FSR 6.0 kHz Bandwidth at -60 db

Image Rejection 70 db

I.F. Rejection 60 db

Audio Output 25 tow into 500 (nominal)

Characteristic Description

Audio Distortion 5 percent at 5 mw, 350 to 3000 Hz

Desensitization (signal to ±2.5% to -29 dbm;

degrade SINAD 3 db) ±10% to -15 dbm;

±50% to +17 dbm

TRANSMITTER

RF Output Power 0.3 W (PEP) for RT-1209, 20W (PEP or

average) with AM-6874

Intermodulation Distortion (IMD) -25 db (two equal tones at rated output

power

Harmonic Radiation -50 db

Carrier Suppression -42 db

Unwanted Sideband Suppression -45 db

All Other Spurious -45 to -60 db

Duty Cycle 1 minute continuous keydown, 9:1

transmit/receive ratio

BATTERY PACK

Battery Silver-zinc (AgZn), rechargeable 4.8 AH

1