Sun. Water. Life.

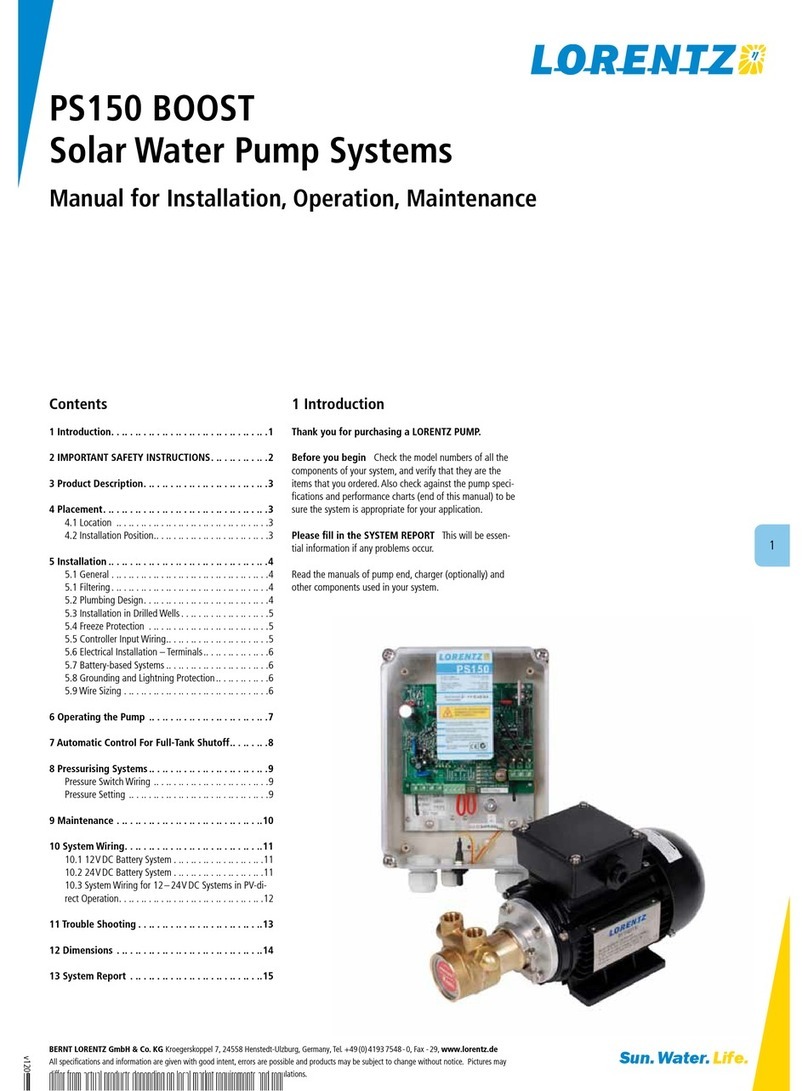

BERNT LORENTZ GmbH & Co. KG Kroegerskoppel 7, 24558 Henstedt-Ulzburg, Germany, Tel. +49 (0) 4193 7548 - 0, Fax - 29, www.lorentz.de

All specifications and information are given with good intent, errors are possible and products may be subject to change without notice. Pictures may

differ from actual products depending on local market requirements and regulations.

v120917

4

2 ELECTRICAL INSTALLATION

WARNING! No disconnect switches

must be installed in power wires

between motor pump controller.

Connecting the motor wire to the

switched-on controller might irreparably damage

it. Such damages are excluded from the warranty.

WARNING! Do not apply a direct

connection or an amp meter

between + and – when the controller

is connected. A short circuit here will

cause a strong discharge.

WARNING! Solar-direct systems only

— Do not connect any electrical load

to the solar array if it is not part of

the LORENTZ PS system. Connection

of active solar tracker controller, electric fence

charger, or other load simultaneously with

LORENTZ PS systems may “confuse” the controller

and prevent proper operation.

System Wiring Diagram for solar-direct systems, refer

to the system diagram in this manual (section 7) and wire

accordingly.

POWER IN Ensure that the solar array DISCONNECT

SWITCH (or circuit breaker) is OFF. In case no disconnect

switch is used, make shade or cover the solar array. Con-

nect the power from the solar array to the input terminals

in the controller box. Observe polarity. If your wires are

not clearly marked +/–, test them using a DC voltmeter or

multitester.

WARNING! To be installed, connected

and serviced by qualified personnel

only. Ensure all power sources are

disconnected when making

connections to the controller. Follow all appropri-

ate electrical codes. No user serviceable parts

inside the motor or the controller!

CAUTION! Loose connections are the

most common cause of system

failures. Pull on each connection to

confirm that it is secure.

3 WIRING ORDER FOR

CORRECT ROTATION

The power wires of the pump have a marking to allow cor-

rect wiring. Connect the power wires using this sequence:

L1

L2

L3

Ground

CAUTION! When splicing the pump

cable, carefully take a note of the

markings of the cables you have

connected.

Testing the pump for direction Helical rotor pumps

will produce water flow only if they are rotating in the right

direction. If you place it in a water tank or a bucket, you

will observe flow if the rotation is correct. Submerge at

least 75% to observe full flow.

Alternative, dry test If you do not have a water vessel

to test the pump in, you can test it dry by watching the

pump shaft and running it for only a few seconds. The

metal label on the pump has an arrow to indicate the

proper direction of rotation. It can be run dry safely for

about 5 seconds. This gives more than enough time to

observe the direction of the shaft.

If you did not write down the colour match (or the wind

blew your note away) connect the three power wires to

the controller in any random order. Apply power. Observe

the pump shaft rotation, then turn the power off. If the

direction is wrong, exchange any two of the power wires at

the controller. In any case, when you are finished connect-

ing the pump to the controller, test it to assure the proper

direction.

Did you install the pump in the well without check-

ing the wiring order or the direction?

OR – Is it running but not pumping?

HELICAL ROTOR pump (no “C” in the model

number) Turn the pump on. Observe if air is rising from

the pipe. If it is not, reverse any two motor wires and ob-

serve again. If you cannot observe air rise, chose whichever

direction is quieter (less vibration). There is risk of dry-run

damage if it runs too long in reverse. If the pump is new

from the factory, it is lubricated so it can run dry for about

90 seconds without risk. If the pump has been used, it

must not be run for more than about 15 seconds. In many

cases, a pump that is reversed will turn off due to overload.

CENTRIFUGAL pump (with “C” in the model

number) In reverse, it will produce no flow (or very little).

This will not damage the pump. If the flow is not normal,

reverse any two motor wires.

Motor cable strain relief: Submersible

motors must use a safety rope or cable

to act as a strain relief for the motor

cable and to avoid losing the pump in

the well if the pipe breaks.

Do not run the motor without the

controller.

To be installed, connected and serviced

by qualified personnel only. Ensure all

power sources are disconnected when

making connections to this unit. Follow all

appropriate electrical codes. There are no user

serviceable parts inside the motor or the controller.

Install proper grounding for safety and

lightning protection.

Do not touch the controller input or

motor wires together to test for a spark.

Protection from solar heatElectronic devices are most

reliable when they are protected from heat. Mount the

controller in the shade of the midday sun. An ideal location

is directly under the solar array, on the North side of the

mounting pole. If no shade is available, cut a piece of sheet

metal and bolt it behind the top of the controller. Bend

it over the controller to provide shade. This is especially

important in extremely hot locations. Extreme heat may

trigger a thermal switch in the controller and cause it to

turn off.

Location of controller Mount the controller vertically

to keep out rainwater. It is preferable to mount it on the

North side of a pole or other structure to help reduce solar

heating. This may also allow easiest access without hitting

your head on the lower (South) edge of the array.

Electrical conduit is recommended We urge you

to use electrical conduit (pipe) to protect outdoor wiring

from the weather, from human activities, and from chewing

animals. If you do not use conduit, use strong, high-quality

outdoor cable. Where cables enter the junction box, install

sealed strain-relief cable clamps.

Keep the controller box sealed Unused holes must

be sealed to keep out small animals, insects, water and dirt.

Each hole is supplied with a rubber plug that can be kept in

place for this purpose.

WARNING! TEST THE VOLTAGE before

connecting power to the controller.

Voltage (open circuit) must not

exceed 375V for PS4000 systems.

(Even in cloudy weather, the open circuit voltage

will be near maximum.)