Lorenz Messtechnik GmbH Obere Schlossstrasse 127/129/131

73553 Alfdorf Phone +49 7172 93730-0, Fax +49 7172 93730-22

Technical changes, errors and misprints excepted. 090374a_LCV-USB3

4/13

If further information is desired or required, or if special problems occur which are not described in

detail in these operating instructions, please contact Lorenz Messtechnik GmbH.

The devices of Lorenz Messtechnik GmbH may only be operated in accordance with the applications

described in these operating instructions. Built-in devices may only be operated if they are properly

installed.

By connecting and commissioning the device, the purchaser accepts the General Terms and Con-

ditions of Sale and Delivery of Lorenz Messtechnik GmbH. Furthermore, the buyer accepts the possi-

ble incompleteness of this operating manual and that the information contained therein may not be

complete and informations are without guarantee. Errors, misprints and changes excepted.

Intended Use, not intended Use

A device from Lorenz Messtechnik GmbH is used for display, processing and control of processes. It

must not be used as the sole means of averting dangerous conditions on machines and systems.

Machines and systems must be designed in such a way that faulty states cannot lead to a dangerous

situation for the operating personnel (e. g. through independent limit value-switches or mechanical

interlocks). In particular, it must be ensured that a the device, its malfunction or its failure does not

lead to damage to property or a loss of that can lead to danger to people. It is also important to prevent

the precautions that are taken from being cannot be circumvented for the safety of a plant. Emergen-

cy stop devices must remain effective at all times.

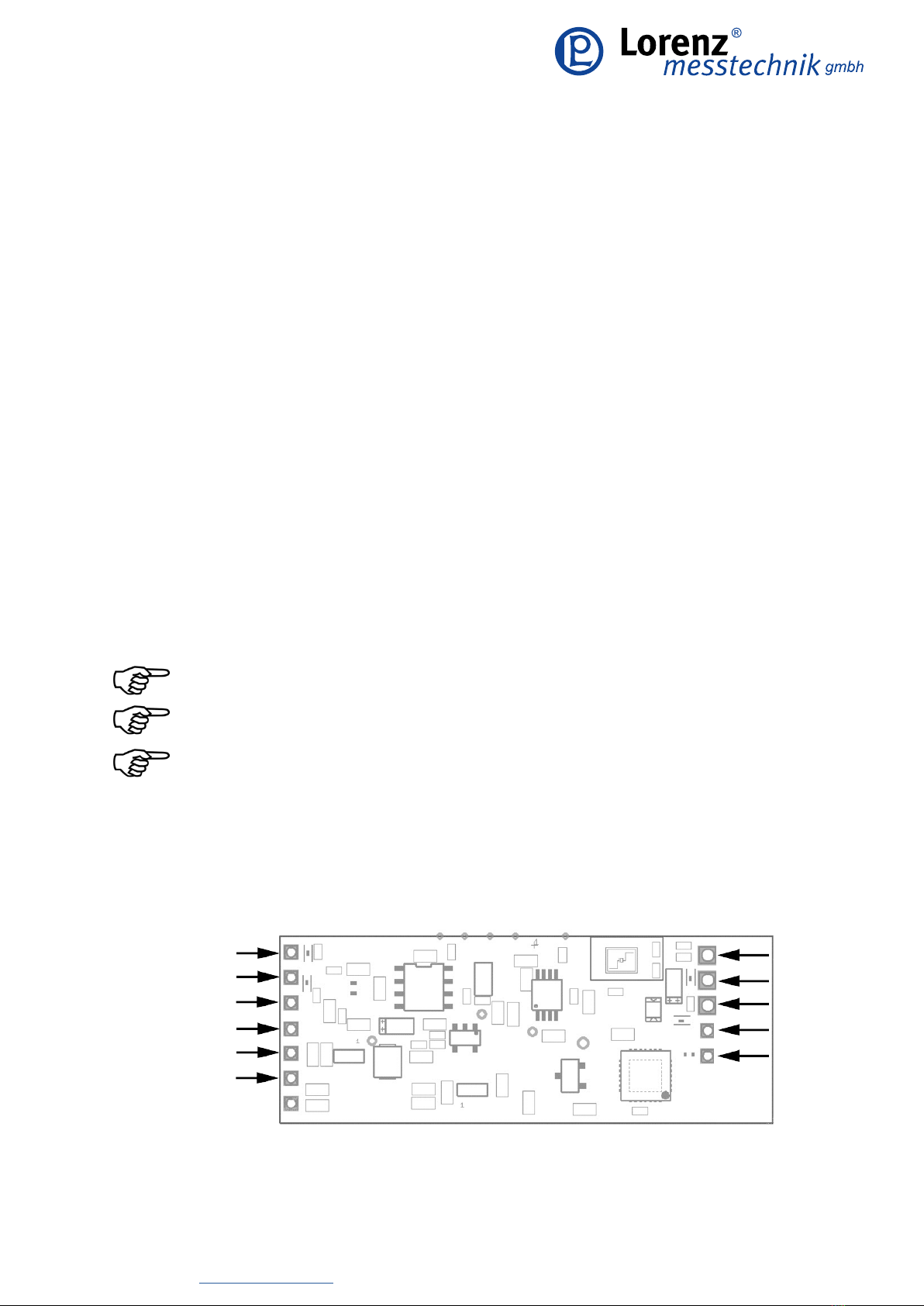

Installation Instructions

Devices from Lorenz Messtechnik GmbH must be installed and connected in compliance with the

relevant DIN and VDE standards. They must be installed in such a way that unintentional operation

issufcientlyexcluded.Topreventaninterruptionofthesupplyandsignallinesfromleadingtoan

undenedor dangerousstate, appropriatehardware andsoftware safetyprecautions mustbe ob-

served.Supply and signallines mustbeinstalled insuch a waythat theydonot interferewith the functionof

the Lorenz Messtechnik GmbH by interfering signals (such as inductive or capacitive interferences).

Notes on Malfunctions, Maintenance and Repair

The devices do not contain any parts that require or can be serviced by the user. Repairs may only

be carried out by Lorenz Messtechnik GmbH. If it can be assumed that safe operation of the device is

no longer possible, it must be put out of operation immediately and secured against unintentional

operation. This applies in particular if:

• The device is visibly damaged

• The device is no longer functional

• Parts of the appliance are loose

• The connecting lines are visibly damaged

In addition, we would like to point out that all obligations of Lorenz Messtechnik GmbH arise exclusi-

vely from the respective purchase contract in which the warranty is conclusively stated.