INDEX

1. GENERAL INFORMATION.........................................................................................................20

1.1. MANUAL USE..............................................................................................................................20

1.1.2. TYPOGRAPHIC INFORMATION......................................................................................................................20

1.2. WARRANTY ................................................................................................................................20

1.3. GENERAL DELIVERY NOTES.........................................................................................................21

1.4. OPTIONAL PARTS .......................................................................................................................21

1.5. PRODUCT MODIFICATIONS........................................................................................................... 21

1.6. MANUFACTURER IDENTIFICATION DATA .......................................................................................21

1.7. AIR FILTER IDENTIFICATION DATA ................................................................................................ 21

1.8. GENERAL SAFETY INFORMATION ................................................................................................. 22

1.8.1. GENERAL SAFETY PROVISIONS ...................................................................................................................22

1.8.2. POSITION OF "DANGER AND WARNING LABELS" ............................................................................................22

1.8.3. NOISE LEVEL.............................................................................................................................................22

1.9. PERSONNEL QUALIFICATION .......................................................................................................22

1.10. DIFFERENT MODELS AND USES: ................................................................................................23

1.11. NON-CONSIDERED USES ...........................................................................................................23

1.12. REQUESTS OF TECHNICAL ASSISTANCE..................................................................................... 23

2. DESCRIPTION ............................................................................................................................23

2.1. FUNCTION AND FIELD OF APPLICATION ........................................................................................23

2.2. TECHNICAL CHARACTERISTICS....................................................................................................24

3. HANDLING AND STORAGE ......................................................................................................24

3.1. HANDLING OF PACKED UNITS ......................................................................................................24

3.2. STORAGE ...................................................................................................................................24

4.INSTALLATION ..........................................................................................................................24

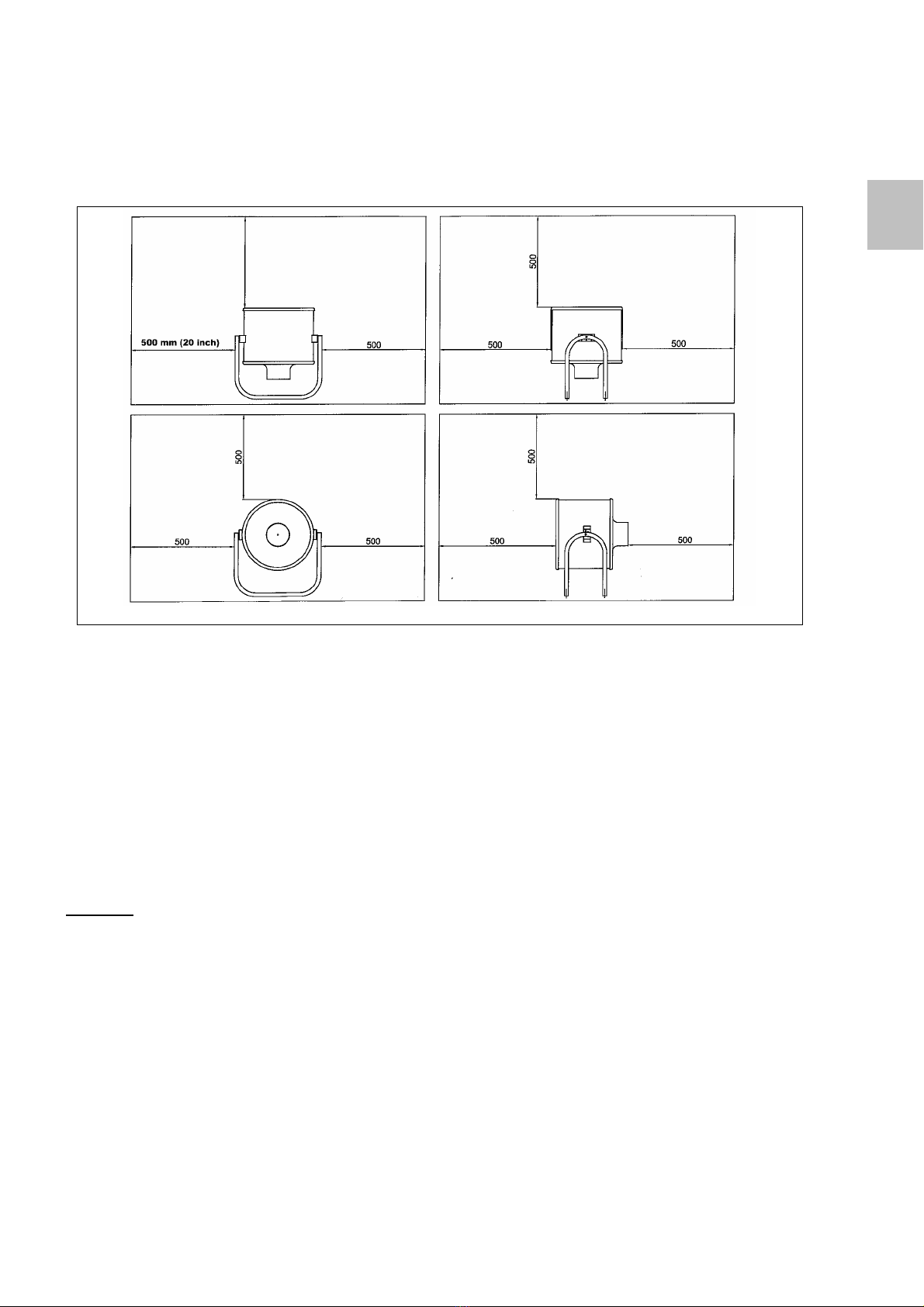

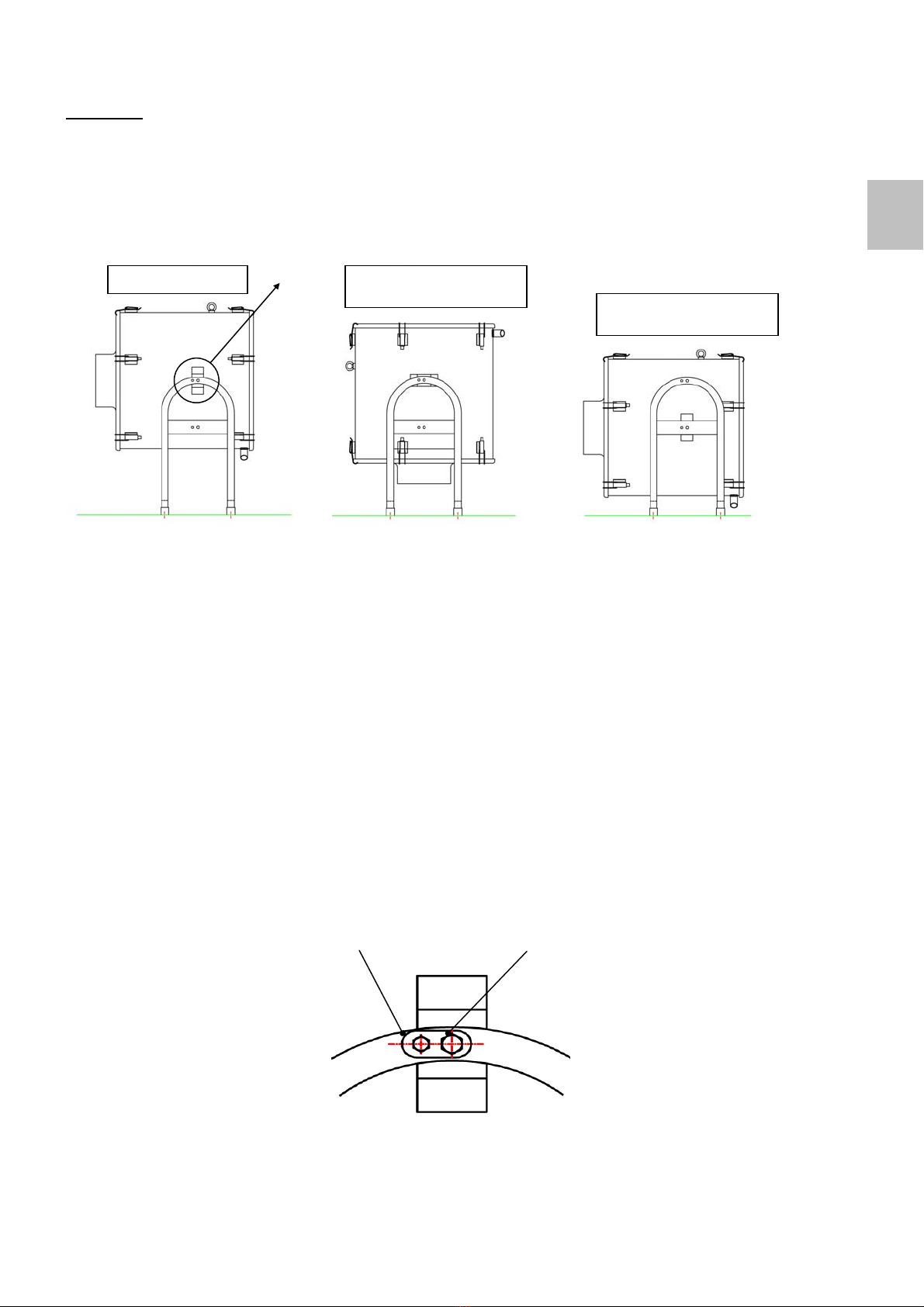

4.1. MINIMUM SPACES FOR INSTALLATION ..........................................................................................25

4.2. CONDITIONS AND OPERATIONALLIMITS ..........................:............................................................25

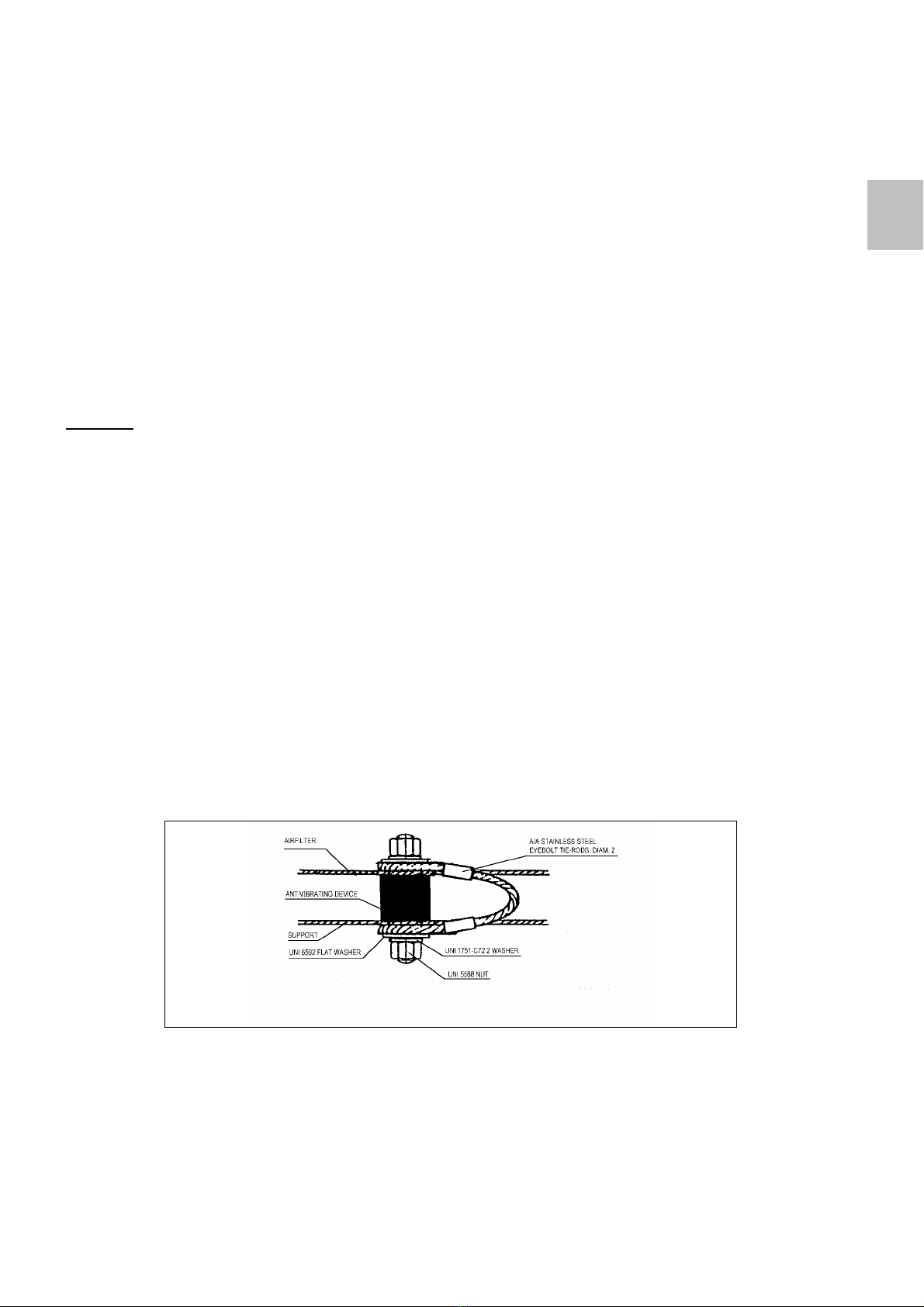

4.3. INSTALLATION ............................................................................................................................26

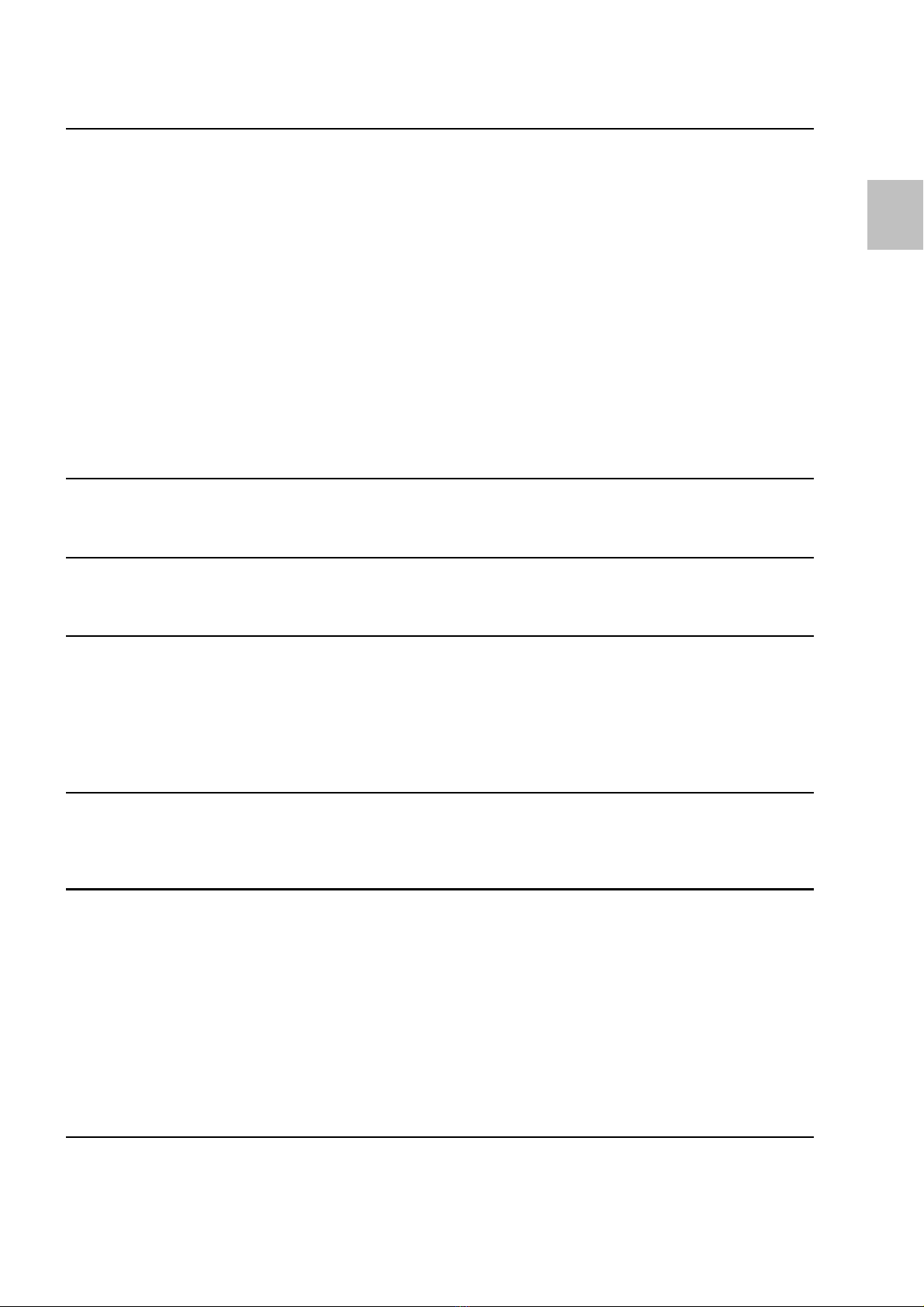

4.3.1. DETERMINATION OF THE FUNCTIONING POSITION:HORIZONTAL OR VERTICAL ...............................................27

4.4. ELECTRICAL CONNECTIONS ........................................................................................................29

4.5.INSPECTION................................................................................................................................30

5. USE .............................................................................................................................................30

5.1. STARTING UP AND STOPPING......................................................................................................30

5.1.1. EMERGENCY STOP ....................................................................................................................................30

5.2. ADVICE FOR CORRECT USE ......................................................................................................... 30

6. MAINTENANCE ..........................................................................................................................30

6.1. OPERATOR QUALIFICATION ......................................................................................................... 30

6.2. EXTERNAL CLEANING .................................................................................................................30

6.3. PROGRAMMED MAINTENANCE .....................................................................................................31

6.3.1. PROGRAMMED MAINTENANCE TABLE........................................................................................................32

6.3.2. ROTOR,SEAL AND FILTER MAINTENANCE....................................................................................................33

6.3.3. FILTER CLEANING ......................................................................................................................................34

6.3.4. INTERNAL CLEANING ..................................................................................................................................34

6.4. SPECIAL MAINTENANCE ..............................................................................................................34

6.4.1. GENERAL DISASSEMBLY AND REASSEMBLY .................................................................................................34

6.4.2. MOTOR MAINTENANCE ...............................................................................................................................35

6.5. STRUCTURAL CHECKS ................................................................................................................36

7. DISPOSAL ..................................................................................................................................36

EN