About the kit

This kit is comprised of a 3D printed plastic body shell, a fret of

etched nickel silver detail parts, a 3D printed brass chassis,

wheels, gears and a motor. Minimal folding of the nickel silver

parts is required and they can all be glued in place. A small

amount of soldering is necessary to complete the electrical

connections. Full assembly instructions are given below.

Due to the nature of the 3D printing process, some support

material may still be present on bottom-facing edges of the body

shell, particularly underneath the buffers. The plastic used has

similar properties to the ABS commonly used in injection-moulded

kits and may be easily cleaned up with a sharp knife and fine

emery boards.

Please note this is a scale model for adult collectors, and not

intended for children under 14 years of age.

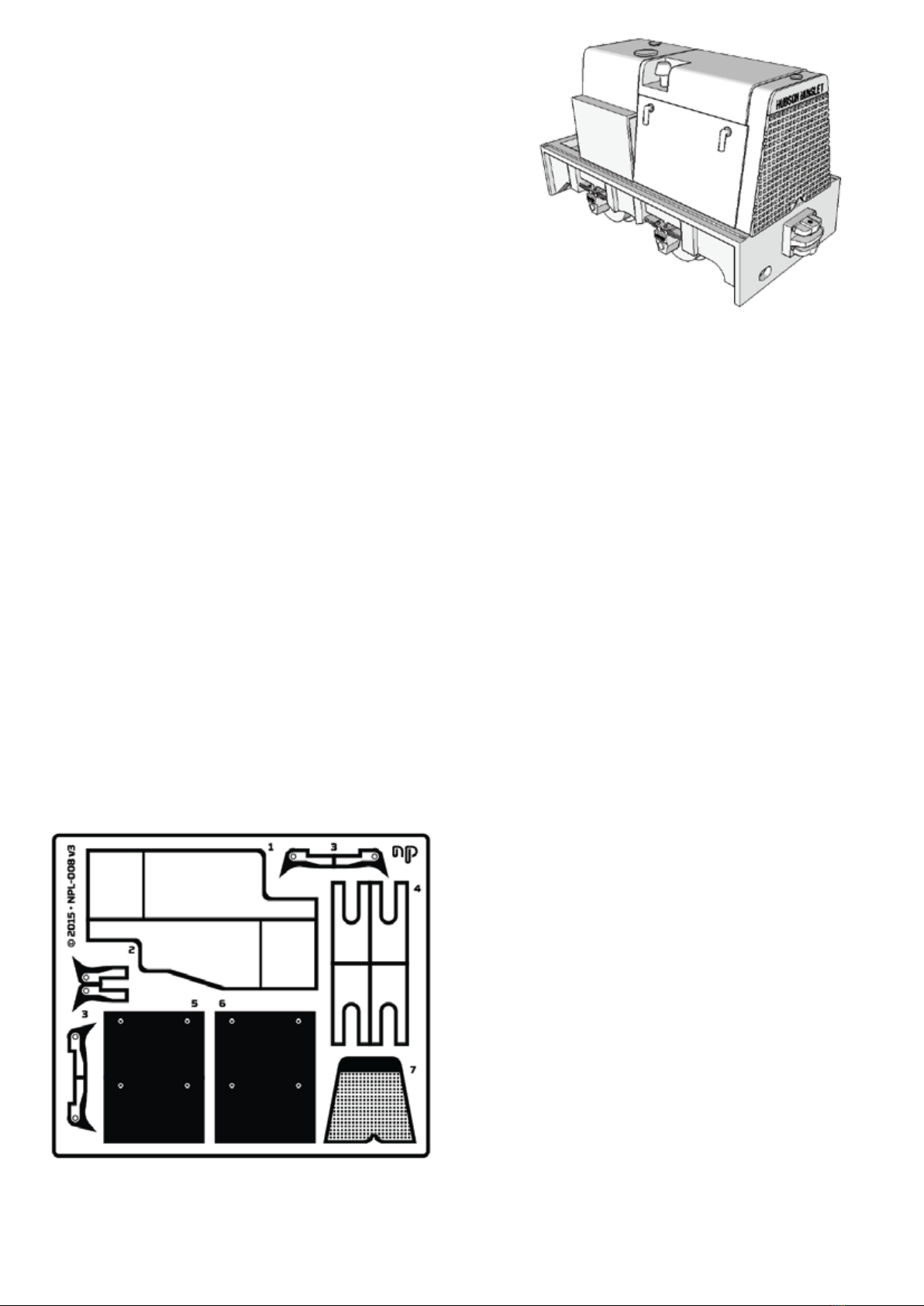

Detail Parts • NPL-008 v3.0

Carefully remove each part from the fret as required using a

sharp knife on a cutting mat or similar hard surface, and clean up

the tags.

Initial preparation

Carefully remove the sprue containing the filler caps from inside

the body print and put safely to one side. Use a small file to

remove any remaining sprue from the body.

Make sure the chassis fits in the body properly as it will be difficult

to alter after assembly. It should be a tight push fit with the

locating pins on the body fitting between the matching pins on the

chassis. If the two parts don’t fit properly then file either the

chassis or body slightly to ensure that they do.

Take the four spacers (4) off the etch and glue or solder them

together in pairs to give yourself two 0.5mm thick parts.

Assembling the Chassis

The layshaft and axles are both notionally 1.5mm in diameter and

the bearing holes have been reamed out to 1.55mm so should be

a smooth fit, but check for burrs on the layshaft ends before fitting

to avoid damaging the bearing surfaces and to ensure that the

brass worms are a sliding fit.

1 • Start by attaching the large pulley to one end of the layshaft

and fixing with Loctite 243 (medium strength threadlocker),

making sure the pulley is square to the shaft. If you need to ream

out the hole do so carefully to make the fit as tight as possible, as

that will help ensure the pulley sits at 90 degrees to the shaft and

doesn’t wobble. File any protruding shaft flat to the face of the

pulley as there is minimal clearance within the body shell.

2 • Slide the layshaft into the chassis from the end with the motor

mount. With the pulley pushed flush against the chassis, trim off

any layshaft that protrudes from the other end of the chassis and

file the end flush to the chassis, then remove the layshaft.

3 • Place the two brass worms into the chassis and then slide the

layshaft back into the chassis through both worms. Do not push

the pulley right up to the chassis, but instead use one of the

0.5mm spacers to keep a gap between the pulley and the chassis.

5. Solid side panels x 2

6. Side panels with grille x 2

7. Front grille

1. Large rear panel

2. Small rear panel

3. Brake shoes x 6

4. Assembly spacers x 4

np

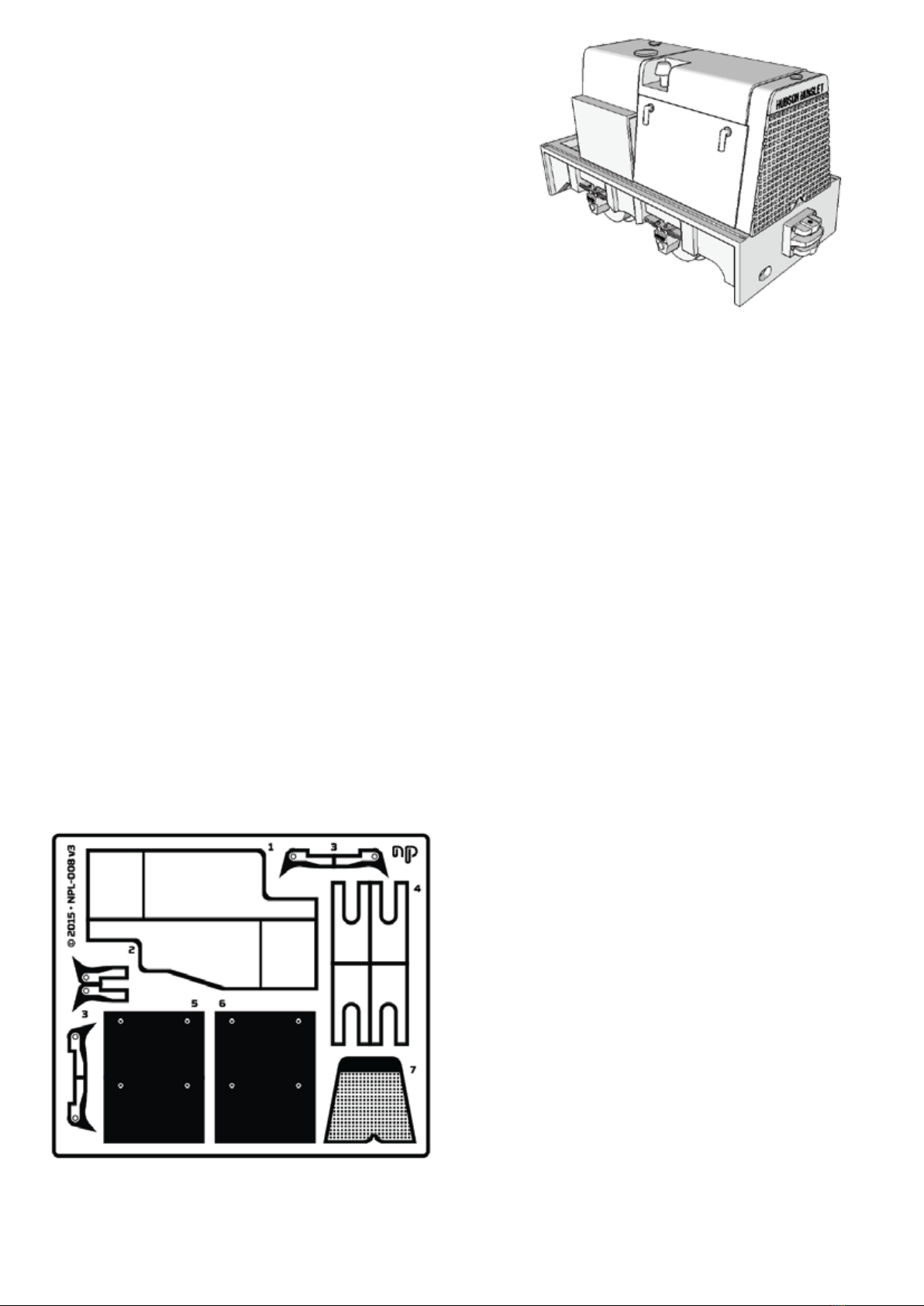

NPL-008

Hudson-Hunslet

24hp light diesel

Thank you for purchasing this Narrow Planet kit, we hope you enjoy building and operating it.

Please read through the instructions thoroughly before beginning assembly.

Prototype Info

Introduced in the late 1950s, the

24hp light diesel locomotive was an

upgraded version of the company’s

original 21hp model and the smallest

in the range. This model, based on

Hunslet’s General Arrangement

Drawing 48937 of April 1961, rep-

resents the basic cabless version.

Many were, however, fitted with

varying designs of cab, and other

equipment, depending upon

intended use.

Preserved examples include

LCWW18, part of the Moseley

Railway Trust collection, and

"Creepy" of the Leighton Buzzard

Railway.

Tools required: Sharp craft knife or scalpel

Razor saw

Tweezers

Flat nosed pliers

Bending bars or engineer's square

Emery paper or boards

Small files

Dressmaker's pins or similar

Reamer (suitable for 0.8mm to 2mm)

1mm drill

Loctite 243

Superglue

Soldering iron and solder (solder

paste is recommended)

4 • Both worms need to be secured to the layshaft flush against

the inside ends of the chassis. In turn, slide each worm as far to the

end of the chassis as it will go. Using a pin add a small amount of

Loctite 243 to the layshaft against the inner end of the worm.

Move the worm along the shaft to pickup the loctite 243 and then

back so it rests against the end of the chassis all the while making

sure to keep the spacer in place so that the pulley is not touching

the end of the chassis. Leave for five minutes for the Loctite 243 to

fully grip and then remove the spacer and check that the shaft

turns freely.

5 • The next job is to prepare the two gears that will fit on to the

axles. We suggest doing this as follows. Gently ream out the gear

until you can just force the brass tubing in; it should be a very tight

fit but if it is at all loose then a small amount of superglue is

advised. With the end of the tube flush to one side of the gear, use a

razor saw to cut the tube leaving around 0.5mm protruding from the

other side. Use a pair of pliers to squeeze the tube to slightly distort it

(this helps the tube grip the axle later) before filing it flush against the

face of the gear. Repeat for the other gear.

6 • Each wheelset is then assembled in the same way. Start by

placing the gear into position with the slightly deformed tube on

the left and then force the axle (to aid assembly the insulated

wheel has already been removed) through from the right hand

side of the chassis. Use one of the spacers to ensure a 0.5mm gap

between the back of the wheel and the side of the chassis and try to

ensure the gear stays in the centre of the space rather than being

forced up against one side. Now gently refit the insulated wheel

making sure it is square to the axle, which is easiest to achieve if you

push on the insulating washer rather than the wheel itself. Use the

spacers to again ensure that that there is a 0.5mm gap between

both wheels and the chassis. Repeat with the other wheelset.

7 • At this point the chassis will not fit in the body as the ends of

the axles get in the way. You need to file the axles back until they

are flush with the face of the wheel. Do this before fitting the

motor to avoid the risk of letting any filings get inside it.

8 • Now superglue the motor onto the motor mount so that the

main face of the motor is level with the outer end of the mount.

Carefully ream out the hole in the small pulley until it will slide onto

the drive shaft – do not force it. Place a small amount of Loctite

243 inside the pulley and slide it on to the motor, and make sure it

is aligned vertically above the main pulley. Leave for a few minutes

for the Loctite 243 to take hold. Now you can fit the drive belt.

9 • At this point you can test that everything works before fitting

the pickups. One approach is to use Blu-tac to hold the chassis

upside down and then temporarily connect it to a standard 12V

power supply via the large resistor (not the tiny surface mount

one). Hopefully everything should run nicely but you might have to

help it on it’s way to start with (push the pulley round whilst under

power) which helps get over any initial tight spots. Once it is

running let it run for an hour in each direction to make sure it is all

nicely run in.

Fitting the pickups

Now that the chassis works the final step is to make sure it can collect

power from the track. This is the most fiddly step so take your time.

There isn’t a lot of space inside the body, especially once the area

above the motor has been filed with weight, so where possible trim

the motor wires as short as you sensibly can, otherwise they may

make it difficult to fit everything inside the body. Read through the

rest of this section to work out where everything goes to help

determine how short the wires can be trimmed.

1 • First you need to solder the red wire directly to the chassis. The

best place to do this is the vertical surface of the motor mount, in

the middle of the chassis above the layshaft, on the side of the

non-insulated wheels. One suggestion is to use a syringe to apply

a small amount of solder paste in the right place, which then helps

to grip the bare end of the wire. A quick dab with a hot soldering

iron and the joint is formed. If any solder runs on to the outside

edges of the chassis file it back, otherwise the chassis might not fit

within the body.

2 • Use a file to make a gap across the middle of the small piece of

PCB. Now solder the resistor to the PCB so that the ends are on

either side of the gap. Solder paste can again be useful to help

hold the resistor in place. Now solder the pickup wire to one end of

the PCB; the wire naturally curves, make sure it curves upwards

away from the PCB when you solder it on.

3 • Feed the black wire down through the centre of the chassis on

the same side of the layshaft as the non-insulated wheels and

solder to near the resistor on the opposite side to the pickup strip.

Now gently position the PCB so that it lays flat, resistor down-

wards, on the bottom of the chassis and the pickups touch the top

of the wheels. Once you are happy with the positioning use a small

amout of superglue to fix it in place and trim the pickup wire to

length if necessary. You should now be able to place the chassis on

the track and see it move, although you may need to tweak the

pickups to get it to work reliably.

4 • The final step in assembling the chassis is to fit the brake shoes

(3). Remove each one from the etch and fold the end over. Once

folded they glue on to the protruding parts of the chassis at the

outer side of each wheel. Make sure that they don’t touch the

wheels as not only will this damage them but if they touch the

insulated wheels they will cause a short circuit. With everything

assembled the chassis should now slide into the body. It will be a

tight fit and the easiest way to remove it is to use a pair of pliers to

grip one of the axle mounts and gently pull.

Assembling the body

The printed body will have been cleaned before packing, but may

need a small amount of preparation before assembly. Check for

any rough surfaces and smooth these gently before starting to

assemble the body; you can easily smooth the surfaces by gently

rubbing with a coffee stirrer.

1 • There isn’t much space to add weight to the model, but as much

as possible of the body has been hollowed out so that Liquid

Gravity or similar can be added. With the body upside down you

can gently add weight into the space above where the motor fits,

allowing it to run back into the control panel area as well. Make

sure that the weight does not protrude too far down into the open

space otherwise the motor will not fit. Fix the weight in place using

superglue. Once dry, check that the chassis still fits properly. If not use

a file to remove any protruding bits. You can also add weight behind

the front buffer, again being careful not to obscure the opening in the

body through which the chassis fits. You can probably also squeeze a

tiny amount of weight into the starter battery!

2 • There are four cab control handles to fit from the 0.45mm brass

wire. Two levers are made from straight pieces of wire. These are

fitted into the hole in the footwell and into the bottom hole on the

control panel. The top control panel hole takes a short piece of wire

with the protruding end bent up at 90 degrees. The final lever is

inserted into the floor and bends at almost 90 degrees just after

leaving the hole to run alongside the driver position. When fitting the

final lever make sure the wire does not protrude out the bottom of

the hole otherwise it will interfere with the chassis preventing the

model from working properly.

3 • Insert a small piece of 0.45mm brass wire through the hole in

each coupling block leaving a short pin protruding from the top. This

will allow other stock using Greenwich couplings (or compatible) to be

coupled to the locomotive.

4 • Two types of side panel are supplied - one solid (5) and one with a

small grille hole (6). Prototype locos seemed to be fitted with either.

To detail the panels, first tape a small thin piece of cardboard to the

outer surface of each piece just below the two holes. Cut the 0.33mm

nickel silver wire into four equal parts. Introduce a right angle bend

close to one end of a piece of wire and then slide the short end

through the hole and use another bit of tape to hold it in position.

Repeat for the other handle. Turn the panel over and apply a small

drop of superglue to each wire. One the glue has set trim the wire back

flush with the inside of the panel and then remove all the tape and card.

Trim the handles to a sensible length. Repeat for the other panel.

If using the panels with grille hole, to fix the mesh use a small piece of

tape to hold it to the inside of the panel, then carefully apply a small

bead of superglue along the edges of the mesh. Try to ensure it

doesn’t run onto the central part that will be visible from the outside.

Once dry remove the tape. You can now glue each panel onto the body

making sure to align the edges with the top part of the engine cover.

5 • Two different shaped rear panels are provided in the kit. The

slightly larger part (1) is intended to be fitted to cabless locomotives,

while the smaller part (2) works better when one of optional cab designs

(available separately) is to be fitted. Assuming you intend to fit the two

filler caps, start by drilling 1mm diameter holes through the rear etched

part using the two half etched holes as guides. Now gently fold the part

to shape so that it fits tightly over the body. If you find the fit isn’t quite

perfect you may need to file a small amount off the body.

Once you are happy with the fit use a small amount of superglue to

fix it in place. Once the glue has dried use a small file to round off the

top two folds to better match the curve of the front of the model. If

fitting the filler caps, drill 1mm holes into the plastic body through the

holes you previously drilled into the etched part. Check that the two

caps slide into the holes (the larger one should be towards the front

of the cab and sits flush to the body, while the smaller one should sit

slightly proud) and then glue into place.

6 • The supplied driver figure is initially a little too fat to fit in the seat.

You‘ll need to use a small file to gently remove some of his upper left

arm, right thigh, and feet until you can gently slide him into position.

7 • The final part to fit is the front grille (7). As it is impossible to paint

the area behind the grille after this has been fitted you may wish to

paint the model and grille separately and then glue the grille in place,

or at least paint the area behind the grille black before fitting it.

8 • The completed model can be painted using any of the common

modelling paints (acrylic or enamel). An initial layer of primer is

recommended to provide a consistent surface and colour as a basis

for final painting.

Acknowledgements

We would like to thank Rod Allcock, Jeff Bissonette, Neil Sayer and

the many members of the 009 Society and NGRM-Online who

provided feedback and support during the development of this kit.

About Narrow Planet

Narrow Planet was founded in 2010 and offers a custom etching

service for unique nameplates, works plates and number plates for

your model railway locos and stock. In any size or shape from 2mm:ft

to 16mm:ft scales. Many manufacturers’ styles are available, our full

range and ordering information can be found on our website. This kit

was designed by Mark A. Greenwood. If you have any queries about

the model or instructions please get in touch.

Contact Details

www.narrowplanet.co.uk

info@narrowplanet.co.uk

27 Terminus Avenue, Bexhill-on-Sea,

East Sussex, TN39 3LS

NPL-008 • first issue • October 2015