11 Lubemate | Digital Preset Oil Control Gun

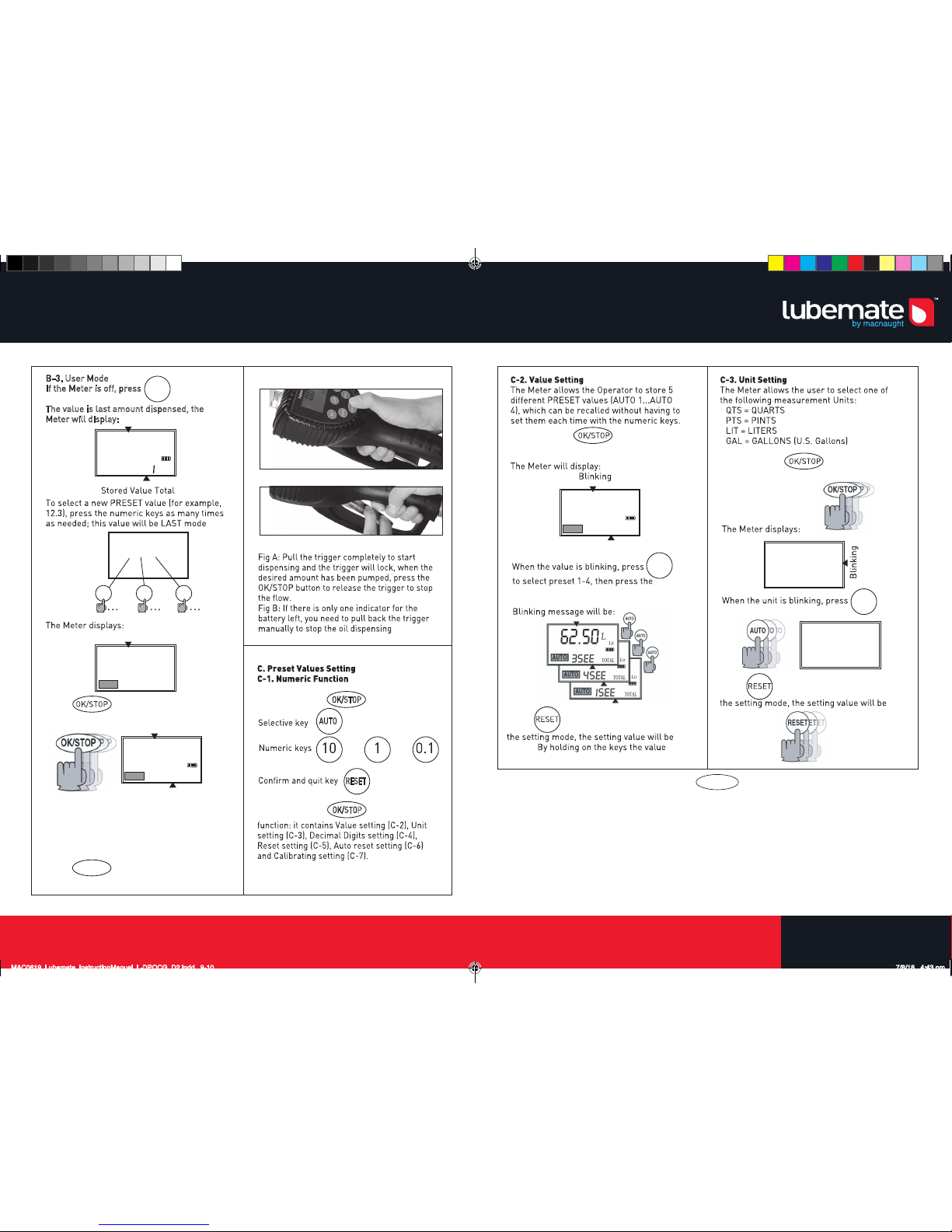

C-4. Decimal Digits Setting

three times to

OK/STOP

Press and hold

set the function.

The Meter will display:

Blinking point

When the number point is blinking, press

AUTO to select location of the point to

confirm the number of decimal digits setting.

to confirm the value and quit

RESET

Press

the setting mode. The setting value will be

stored.

NOTE:

•

The Meter displays the FLOATING POINT

Batch total dispensed.

•Independent of the selection carried out

(two or three decimal digits), as soon as

the amount dispensed exceeds 10 units,

the Meter displays only

two decimal digits.

•As soon as the amount dispensed exceeds

99 units, the Meter displays only

one

decimal digit.

Press

RESET

C-5. Reset Setting

four times to set

OK/STOP

Press and hold

the function.

The Meter displays:

Blinking

to

AUTO

When YES is blinking, press

select YES or No. If YES the batch total will

be set to

button for 10 zero after hold

OK/STOP

seconds, NO to cancel.

to confirm the value and quit

the setting mode. The setting value will be

stored.

NOTE:

Independent of the selection carried

out,

the Batch Total supplied is never reset if

the dispensing operation has been carried out

in AUTO mode.

yes

1see

AUTO

C-6. Auto Reset Setting

The function described in this paragraph concerns

only those who want to obtain the

maximum dispensing stop precision in AUTO mode.

If a slight excess of the pre-set value (a

few hundredths of a quart) does not cause any problem,

the following paragraphs can be

ignored.

The Meter in AUTO mode allows the user to obtain a highly precise stop, thus dispensing

exactly the pre-set amount without exceeding the PRESET value.

To guarantee this high stop precision, especially when the unit operates at the maximum

allowed flow rates, dispensing does not stop when the PRESET value is reached, but instead

when the PRESET value reaches a few Unit hundredths.

If the METER is used:

•

With fluids having a viscosity close to the limits of the allowed range

(such as

low-viscosity antifreeze fluids or high-viscosity oils for gear boxes).

•

In extreme flow rate conditions

(close to the min. and max. value of the allowed range), it

may be necessary to carry out an on-site calibration.

The Meter allows the user to carry out a rapid electronic calibration by modifying the

Calibration factor (K Factor).

At delivery all meters are given the same calibration factor:

K Factor = 1.000

This calibration factor guarantees the best accuracy in the following operating conditions:

Fluid: Motor oil type 10W 30 Temperature: 68°F Flow-rate: 2.6 GPM

The calibration can be done either as:

• An on-site calibration by dispensing into a calibrated container or

• A direct modification of the calibration factor.

To guarantee the stop precision,

this pre-stop value must not be fixed

, but is dependent on the

flow rate used. To allow the operator to obtain the highest stop precision, the unit is equipped

with a Stop Precision factor, called PS factor.

The operator can customize the Meter to

select a PS factor between ZERO and FOUR.

Why calibrate?

How to calibrate

On-site calibration by dispensing into a

calibrated container:

Press and hold down six times

OK/STOP

to set the function.

The Meter will display:

Blinking point

Press

AUTO

; start the calibration by

dispensing the fluid into a calibrated

container.

The dispensing operation may be interrupted

and resumed.

The calibrated dispensing is complete when

the level of the fluid reaches the graduated

area of the calibrated container.

The Meter displays:

6.95

Blinking point

Indicated value

6.90

Lit

CAL

CRL

Lit

1-000

INSTRUCTION MANUAL

INSTRUCTION MANUAL

C-4. Decimal Digits Setting

three times to

OK/STOP

Press and hold

set the function.

The Meter will display:

Blinking point

When the number point is blinking, press

AUTO to select location of the point to

confirm the number of decimal digits setting.

to confirm the value and quit

RESET

Press

the setting mode. The setting value will be

stored.

NOTE:

•

The Meter displays the FLOATING POINT

Batch total dispensed.

•Independent of the selection carried out

(two or three decimal digits), as soon as

the amount dispensed exceeds 10 units,

the Meter displays only

two decimal digits.

•As soon as the amount dispensed exceeds

99 units, the Meter displays only

one

decimal digit.

Press

RESET

C-5. Reset Setting

four times to set

OK/STOP

Press and hold

the function.

The Meter displays:

Blinking

to

AUTO

When YES is blinking, press

select YES or No. If YES the batch total will

be set to

button for 10 zero after hold

OK/STOP

seconds, NO to cancel.

to confirm the value and quit

the setting mode. The setting value will be

stored.

NOTE:

Independent of the selection carried

out,

the Batch Total supplied is never reset if

the dispensing operation has been carried ou

C-6. Auto Reset Setting

The function described in this paragraph concerns

only those who want to obtain the

maximum dispensing stop precision in AUTO mode.

If a slight excess of the pre-set value (a

few hundredths of a quart) does not cause any problem,

the following paragraphs can be

ignored.

The Meter in AUTO mode allows the user to obtain a highly precise stop, thus dispensing

exactly the pre-set amount without exceeding the PRESET value.

To guarantee this high stop precision, especially when the unit operates at the maximum

allowed flow rates, dispensing does not stop when the PRESET value is reached, but instead

when the PRESET value reaches a few Unit hundredths.

If the METER is used:

•

With fluids having a viscosity close to the limits of the allowed range

(such as

low-viscosity antifreeze fluids or high-viscosity oils for gear boxes).

•

In extreme flow rate conditions

(close to the min. and max. value of the allowed range), it

may be necessary to carry out an on-site calibration.

The Meter allows the user to carry out a rapid electronic calibration by modifying the

Calibration factor (K Factor).

At delivery all meters are given the same calibration factor:

K Factor = 1.000

This calibration factor guarantees the best accuracy in the following operating conditions:

Fluid: Motor oil type 10W 30 Temperature: 68°F Flow-rate: 2.6 GPM

The calibration can be done either as:

• An on-site calibration by dispensing into a calibrated container or

• A direct modification of the calibration factor.

To guarantee the stop precision,

this pre-stop value must not be fixed

, but is dependent on the

flow rate used. To allow the operator to obtain the highest stop precision, the unit is equipped

with a Stop Precision factor, called PS factor.

The operator can customize the Meter to

select a PS factor between ZERO and FOUR.

Why calibrate?

How to calibrate

On-site calibration by dispensing into a

calibrated container:

Press and hold down six times

OK/STOP

to set the function.

The Meter will display:

Blinking point

Press

AUTO

; start the calibration by

dispensing the fluid into a calibrated

container.

The dispensing operation may be interrupted

and resumed.

The calibrated dispensing is complete when

the level of the fluid reaches the graduated

area of the calibrated container.

The Meter displays:

6.95

Blinking point

Indicated value

6.90

Lit

CAL

CRL

Lit

1-000

INSTRUCTION MANUAL

INSTRUCTION MANUAL

C-4. Decimal Digits Setting

three times to

OK/STOP

Press and hold

set the function.

The Meter will display:

Blinking point

When the number point is blinking, press

AUTO to select location of the point to

confirm the number of decimal digits setting.

to confirm the value and quit

RESET

Press

the setting mode. The setting value will be

stored.

NOTE:

•

The Meter displays the FLOATING POINT

Batch total dispensed.

•Independent of the selection carried out

(two or three decimal digits), as soon as

the amount dispensed exceeds 10 units,

the Meter displays only

two decimal digits.

•As soon as the amount dispensed exceeds

99 units, the Meter displays only

one

decimal digit.

Press

RESET

C-5. Reset Setting

four times to set

OK/STOP

Press and hold

the function.

The Meter displays:

Blinking

to

AUTO

When YES is blinking, press

select YES or No. If YES the batch total will

be set to

button for 10 zero after hold

OK/STOP

seconds, NO to cancel.

to confirm the value and quit

the setting mode. The setting value will be

stored.

NOTE:

Independent of the selection carried

out,

the Batch Total supplied is never reset if

the dispensing operation has been carried out

in AUTO mode.

00.00

L

Lit

0

TOTAL

yes

1see

AUTO

C-6. Auto Reset Setting

The function described in this paragraph concerns

only those who want to obtain the

maximum dispensing stop precision in AUTO mode.

If a slight excess of the pre-set value (a

few hundredths of a quart) does not cause any problem,

the following paragraphs can be

ignored.

The Meter in AUTO mode allows the user to obtain a highly precise stop, thus dispensing

exactly the pre-set amount without exceeding the PRESET value.

To guarantee this high stop precision, especially when the unit operates at the maximum

allowed flow rates, dispensing does not stop when the PRESET value is reached, but instead

when the PRESET value reaches a few Unit hundredths.

If the METER is used:

•

With fluids having a viscosity close to the limits of the allowed range

(such as

low-viscosity antifreeze fluids or high-viscosity oils for gear boxes).

•

In extreme flow rate conditions

(close to the min. and max. value of the allowed range), it

may be necessary to carry out an on-site calibration.

The Meter allows the user to carry out a rapid electronic calibration by modifying the

Calibration factor (K Factor).

At delivery all meters are given the same calibration factor:

K Factor = 1.000

This calibration factor guarantees the best accuracy in the following operating conditions:

Fluid: Motor oil type 10W 30 Temperature: 68°F Flow-rate: 2.6 GPM

The calibration can be done either as:

• An on-site calibration by dispensing into a calibrated container or

• A direct modification of the calibration factor.

To guarantee the stop precision,

this pre-stop value must not be fixed

, but is dependent on the

flow rate used. To allow the operator to obtain the highest stop precision, the unit is equipped

with a Stop Precision factor, called PS factor.

The operator can customize the Meter to

select a PS factor between ZERO and FOUR.

Why calibrate?

How to calibrate

On-site calibration by dispensing into a

calibrated container:

Press and hold down six times

OK/STOP

to set the function.

The Meter will display:

Blinking point

Press

AUTO

; start the calibration by

dispensing the fluid into a calibrated

container.

The dispensing operation may be interrupted

and resumed.

The calibrated dispensing is complete when

the level of the fluid reaches the graduated

area of the calibrated container.

The Meter displays:

6.95

Blinking point

Indicated value

6.90

Lit

CAL

INSTRUCTION MANUAL

C-4. Decimal Digits Setting

three times to

OK/STOP

Press and hold

set the function.

The Meter will display:

Blinking point

When the number point is blinking, press

AUTO to select location of the point to

confirm the number of decimal digits setting.

to confirm the value and quit

RESET

Press

the setting mode. The setting value will be

stored.

NOTE:

•

The Meter displays the FLOATING POINT

Batch total dispensed.

•Independent of the selection carried out

(two or three decimal digits), as soon as

the amount dispensed exceeds 10 units,

the Meter displays only

two decimal digits.

•As soon as the amount dispensed exceeds

99 units, the Meter displays only

one

decimal digit.

Press

RESET

C-5. Reset Setting

four times to set

OK/STOP

Press and hold

the function.

The Meter displays:

Blinking

to

AUTO

When YES is blinking, press

select YES or No. If YES the batch total will

be set to

button for 10 zero after hold

OK/STOP

seconds, NO to cancel.

to confirm the value and quit

the setting mode. The setting value will be

stored.

NOTE:

Independent of the selection carried

out,

the Batch Total supplied is never reset if

the dispensing operation has been carried out

in AUTO mode.

00.00

L

Lit

0

TOTAL

yes

1see

AUTO

C-6. Auto Reset Setting

The function described in this paragraph concerns

only those who want to obtain the

maximum dispensing stop precision in AUTO mode.

If a slight excess of the pre-set value (a

few hundredths of a quart) does not cause any problem,

the following paragraphs can be

ignored.

The Meter in AUTO mode allows the user to obtain a highly precise stop, thus dispensing

exactly the pre-set amount without exceeding the PRESET value.

To guarantee this high stop precision, especially when the unit operates at the maximum

allowed flow rates, dispensing does not stop when the PRESET value is reached, but instead

when the PRESET value reaches a few Unit hundredths.

If the METER is used:

•

With fluids having a viscosity close to the limits of the allowed range

(such as

low-viscosity antifreeze fluids or high-viscosity oils for gear boxes).

•

In extreme flow rate conditions

(close to the min. and max. value of the allowed range), it

may be necessary to carry out an on-site calibration.

The Meter allows the user to carry out a rapid electronic calibration by modifying the

Calibration factor (K Factor).

At delivery all meters are given the same calibration factor:

K Factor = 1.000

This calibration factor guarantees the best accuracy in the following operating conditions:

Fluid: Motor oil type 10W 30 Temperature: 68°F Flow-rate: 2.6 GPM

The calibration can be done either as:

• An on-site calibration by dispensing into a calibrated container or

• A direct modification of the calibration factor.

To guarantee the stop precision,

this pre-stop value must not be fixed

, but is dependent on the

flow rate used. To allow the operator to obtain the highest stop precision, the unit is equipped

with a Stop Precision factor, called PS factor.

The operator can customize the Meter to

select a PS factor between ZERO and FOUR.

Why calibrate?

How to calibrate

On-site calibration by dispensing into a

calibrated container:

Press and hold down six times

OK/STOP

to set the function.

The Meter will display:

Blinking point

Press

AUTO

; start the calibration by

dispensing the fluid into a calibrated

container.

The dispensing operation may be interrupted

and resumed.

The calibrated dispensing is complete when

the level of the fluid reaches the graduated

area of the calibrated container.

The Meter displays:

6.95

Blinking point

Indicated value

6.90

Lit

CAL

CRL

Lit

1-000

INSTRUCTION MANUAL

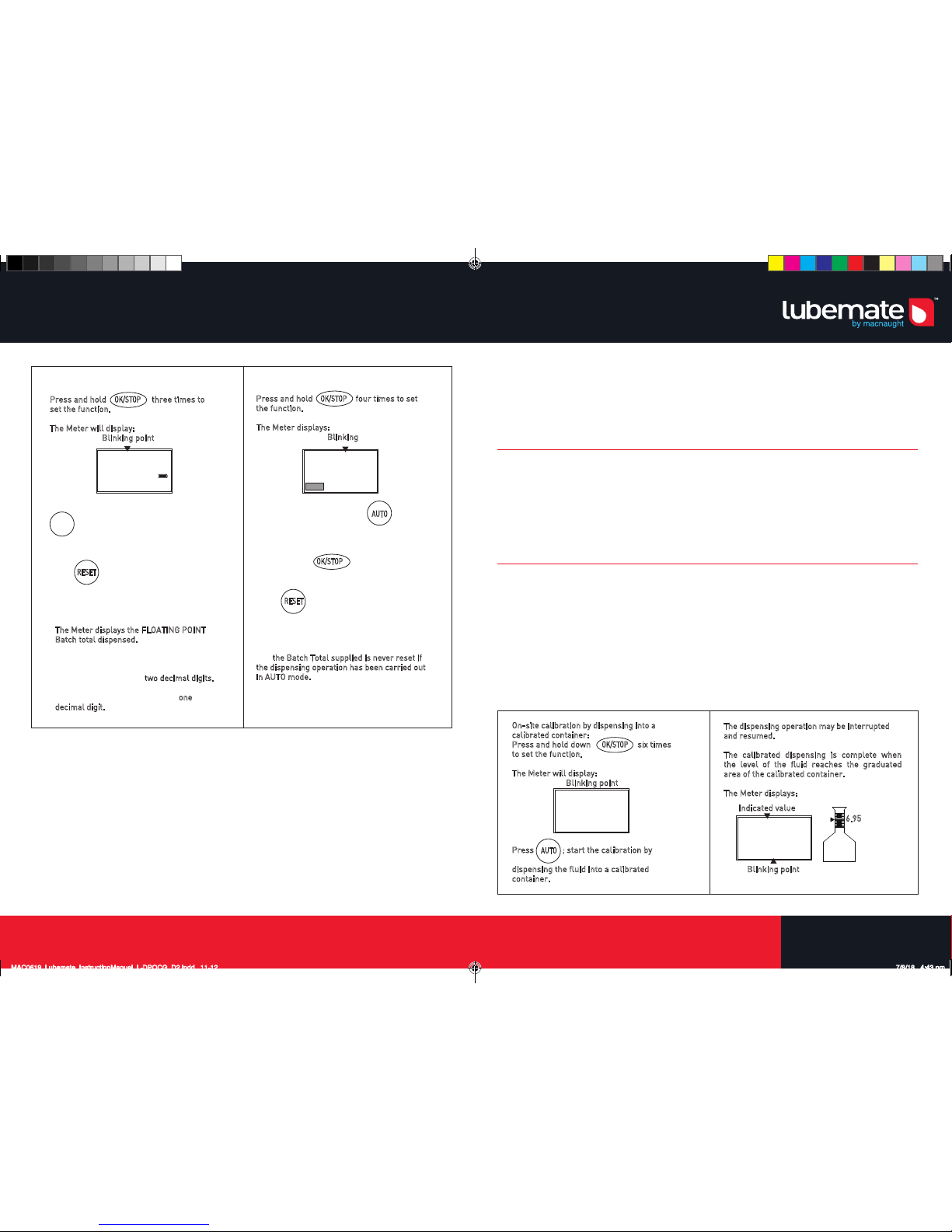

C-6. Auto reset setting

The function described in this paragraph concerns only those who want to obtain the maximum

dispensing stop precision in AUTO mode. If a slight excess of the pre-set value (a few hundredths of a

quart) does not cause any problem, the following paragraphs can be ignored.

The Meter in AUTO mode allows the user to obtain a highly precise stop, thus dispensing exactly the

pre-set amount without exceeding the PRESET value.

To guarantee this high stop precision, especially when the unit operates at the maximum allowed flow

rates, dispensing does not stop when the PRESET value is reached, but instead when the PRESET value

reaches a few Unit hundredths.

To guarantee the stop precision, this pre-stop value must not be fixed, but is dependent on the flow rate

used. To allow the operator to obtain the highest stop precision, the unit is equipped with a Stop Precision

factor, called PS factor.

The operator can customize the Meter to select a PS factor between ZERO and FOUR.

WHY CALIBRATE?

If the METER is used:

• With fluids having a viscosity close to the limits of the allowed range (such as low-viscosity

antifreeze fluids or high-viscosity oils for gear boxes).

• In extreme flow rate conditions (close to the min. and max. value of the allowed range),

it may be necessary to carry out an on-site calibration.

HOW TO CALIBRATE

The Meter allows the user to carry out a rapid electronic calibration by modifying the

Calibration factor (K Factor).

At delivery all meters are given the same calibration factor:

K Factor = 1.000

This calibration factor guarantees the best accuracy in the following operating conditions:

Fluid: Motor oil type 10W 30 Temperature: 68°F Flow-rate: 2.6 GPM

The calibration can be done either as:

• An on-site calibration by dispensing into a calibrated container or

• A direct modification of the calibration factor.

MAC0619_Lubemate_InstructionManual_L-DPOCG_D2.indd 11-12 7/8/18 4:43 pm