SECURITY

This section gives a comprehensive overview of all

important safety aspects for optimal protection of

the operator, as well as safe and trouble-free

operation.

Failure to follow the instructions and safety

information provided in this guide may result in

considerable danger.

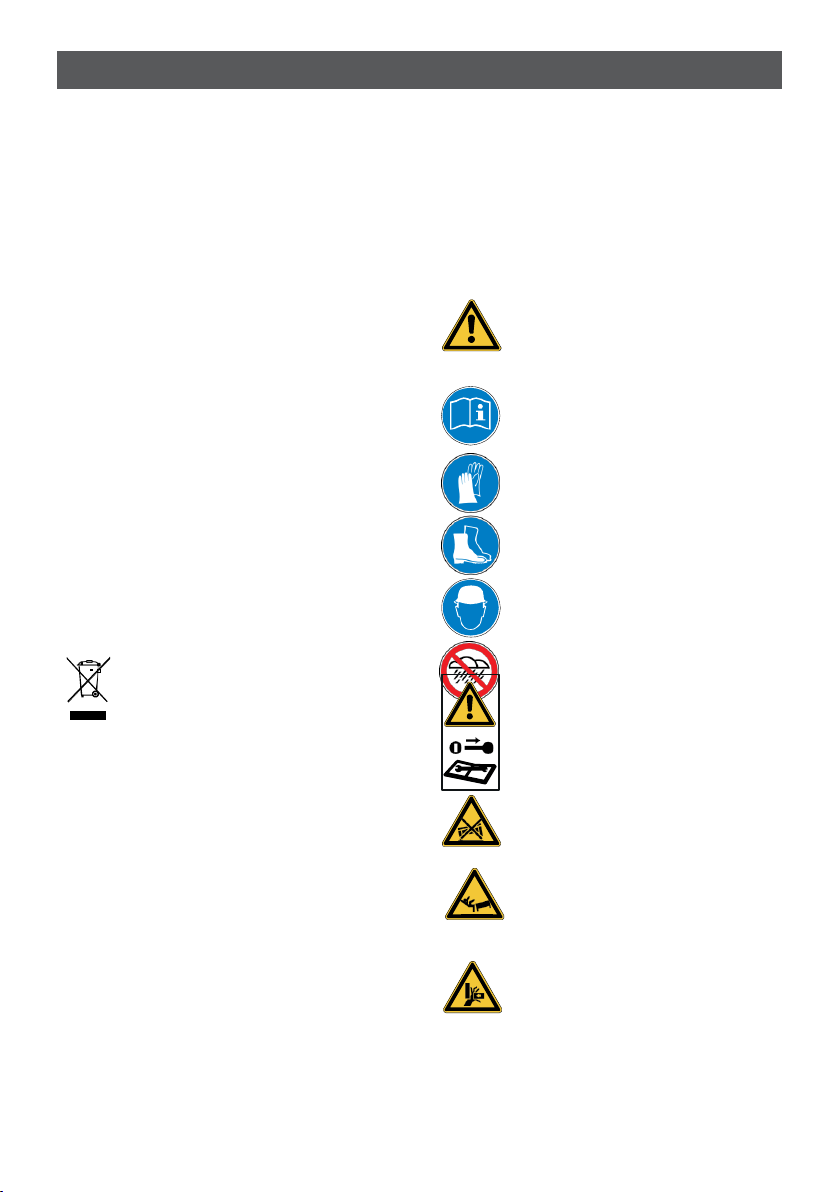

8.1 WARNINGS

Warnings are indicated in this manual by symbols.

The notices referring to your personal safety are

highlighted by a warning triangle, notices referring

only to property damage have no warning triangle.

The instructions must be followed to prevent

accidents, personal injury and property damage.

DANGER!

Failure to follow these instructions highest danger

to life or the risk of life-threatening injuries.

Failure to follow these instructions can be fatal or

serious injury.

Failure to follow these instructions slight to

moderate injury.

Notes

Failure to follow these instructions can result in risk

of damaging the machine or other property.

In addition, the manual contains other important

text which are marked with the word ATTENTION.

8.2 BATTERIES / CHARGER

Use and care of batteries and chargers

Batteries and chargers are not toys and should be

kept out of reach of children. Keep batteries and

chargers out of the reach of children.

Do not open batteries and chargers. There is a risk

of a short circuit. With open components no

guarantee can be given.

Protect batteries and chargers from heat (eg, also

against continuous sun exposure), fire and

immersion in water or other liquids. Risk of

explosion. Likewise, the components must not enter

into the fire or be cremated.

Recharge your battery only with the chargers that

are recommended by the manufacturer. If other

chargers a fire hazard cannot be excluded.

Use Only batteries that are approved by the

manufacturer for the machine. Just so the battery is

protected from dangerous overload. The use of

other batteries can cause injury or fire.

Keep unused batteries away from paper clips,

coins, nails,

screws or other small metal objects that can make

a connection from one terminal. A short-circuit the

battery terminals together may cause burns or a

fire.

If used incorrectly, fluid can leak from the battery.

Avoid contact with. If contact with water rinse. If the

liquid contacts eyes, additionally seek medical help.

Escaping battery fluid may cause skin irritation or

burns.

In case of damage and improper use of batteries

and charger vapors can escape. Run fresh air and

look at complaints consult a physician. The vapors

can irritate the respiratory tract.

7