LUMBERJACK TOOLS PRO Series User manual

MODELS:

Pro Series - TTR0500

Pro Series - TTR0750

Pro Series - TTR1000

Pro Series - TTR1500

Pro Series - TTR2000

Home Series - TRH1000

Home Series - TRH1500

Home Series - TRH2000

Due to continuing improvements, actual product may differ slightly from the product described herein.

USER MANUAL

&

Dual Blade Tenon Cutters

All Rights Reserved.

© 2022 Lumberjack Group, LLC

DBA Lumberjack Tools

www.lumberjacktools.com

Email: [email protected]

Phone: 715-514-0319

2

Our lifetime guarantee covers the tool body and shank. The blades are

covered for 90 days from the date of purchase for breakage under normal

working conditions. Blades will dull faster cutting hardwoods vs

softwoods (peeled or unpeeled). Soil and other abrasive substances will

reduce blade life and is not covered under this warranty. When making a

claim, you must show proof of purchase from an authorized distributor.

This is valid only to the original buyer, and not for tools sold secondhand,

used, or sold “as is” to a second party.

WhatVoidsWarranty

In order to keep our lifetime and 90 day warranty you must AVOID the

following actions:

●Operating the tool in a drill press or lathe (or any system other than

a hand-held drill)

●Running the tool into a nail or foreign object

●Altering or modifying the tool

AboutYourProduct

Thank you for purchasing our Dual Blade - Radius Shoulder Tenon Cutter!

Lumberjack engineers, along with our craftsmen, have designed the

safest, easiest-to-use tenon cutters on the market. By combining old

world skills with 3D CAD modeling and CNC manufacturing, we have

created the ideal tenon cutter: straight tenons, smooth finish, precision

operation, and long tool life.

Dual-bladed tenon tools will cut a tenon in half the time of a single-bladed

tool. Wear is reduced by putting force of cutting across two blades

instead of one. The blades are stamped, heat treated and precision

ground to provide years of service if properly maintained. The Pro Series

tools are machined from a solid aluminum billet and the Home Series

tools are made of die-cast aluminum.

3

SAFETY

Before beginning any project, carefully read and follow ALL safety and

operational instructions for any tools or devices you will be using. Failure to do

so may cause physical harm to yourself or those around you. If you feel

uncomfortable using our tenon cutters or any other tool, STOP immediately.

Lumberjack Tools assumes no responsibility for injury caused to the operator,

bystander, or tools used in conjunction with the use or misuse of our tenon

cutters.

NEVER OPERATE POWER TOOLS UNDER THE INFLUENCE OF

DRUGS, ALCOHOL, OR ANY MEDICATIONS

ALWAYS WEAR SAFETY GLASSES, DUST MASK, AND ANY OTHER

PERSONAL PROTECTION ITEMS AS NEEDED

NEVER WEAR LOOSE ITEMS THAT COULD BE CAUGHT IN MOVING

PARTS. SECURE LOOSE OR LONG HAIR AWAY FROM AREA

WE STRONGLY RECOMMEND A SINGLE-SPEED, GEAR DRIVEN DRILL

WITH RPMS OF 500 OR LESS. EXCEEDING THESE RPMS MAY

RESULT IN DAMAGE TO THE TOOL

ALWAYS DISCONNECT POWER AND ALLOW DRILL TO COME TO A

COMPLETE STOP BEFORE INSTALLING, REMOVING, OR ADJUSTING

THE TOOL

NEVER APPLY BENDING FORCE (SIDE LOADING) TO THE TOOL. SIDE

LOADING COULD CAUSE THE SHANK TO FAIL, OR MAY RESULT IN

BLADE DAMAGE

ALWAYS SECURE THE LOG IN A VISE OR CLAMP PRIOR TO

STARTING YOUR DRILL. FAILURE TO DO SO MAY RESULT IN INJURY

ALWAYS HANDLE THE BLADES WITH EXTREME CARE! FAILURE TO

DO SO MAY RESULT IN SERIOUS INJURY

WHEN EXCESSIVE FORCE IS REQUIRED TO CUT, RE-SHARPEN OR

REPLACE THE BLADES. A SHARP TOOL IS A SAFE TOOL!

NEVER PUT HANDS OR ANY BODY PART INSIDE THE TOOL WHILE THE

BLADES ARE ATTACHED! DOING SO MAY CAUSE SERIOUS INJURY

4

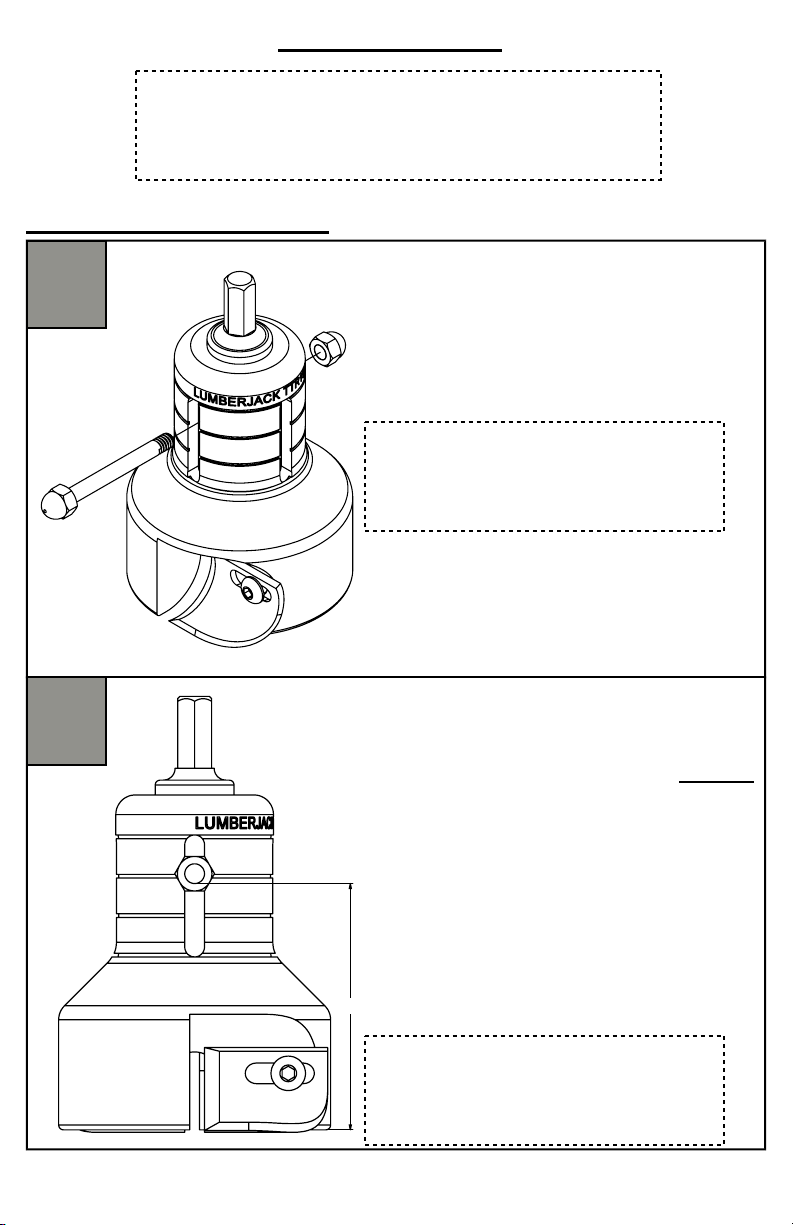

ProSeriesONLY

QuickStopInstallation

●Install the quick stop pin through

the tool body

●Secure with the supplied acorn nut

●The length of the tenon is

determined by measuring from

the face of the tool to the bottom

of the Quick Stop Pin and

subtracting 3/4”

●In the image to the left, dimension

“X” - 3/4” = approximate length of

the tenon

1

2

X

The Quick Stop Pins are not included

with individual tools

NOTE:

NOTE:

For sale separately or

included with kits

NOTE:

For sale separately or

included with kits

5

3/16”

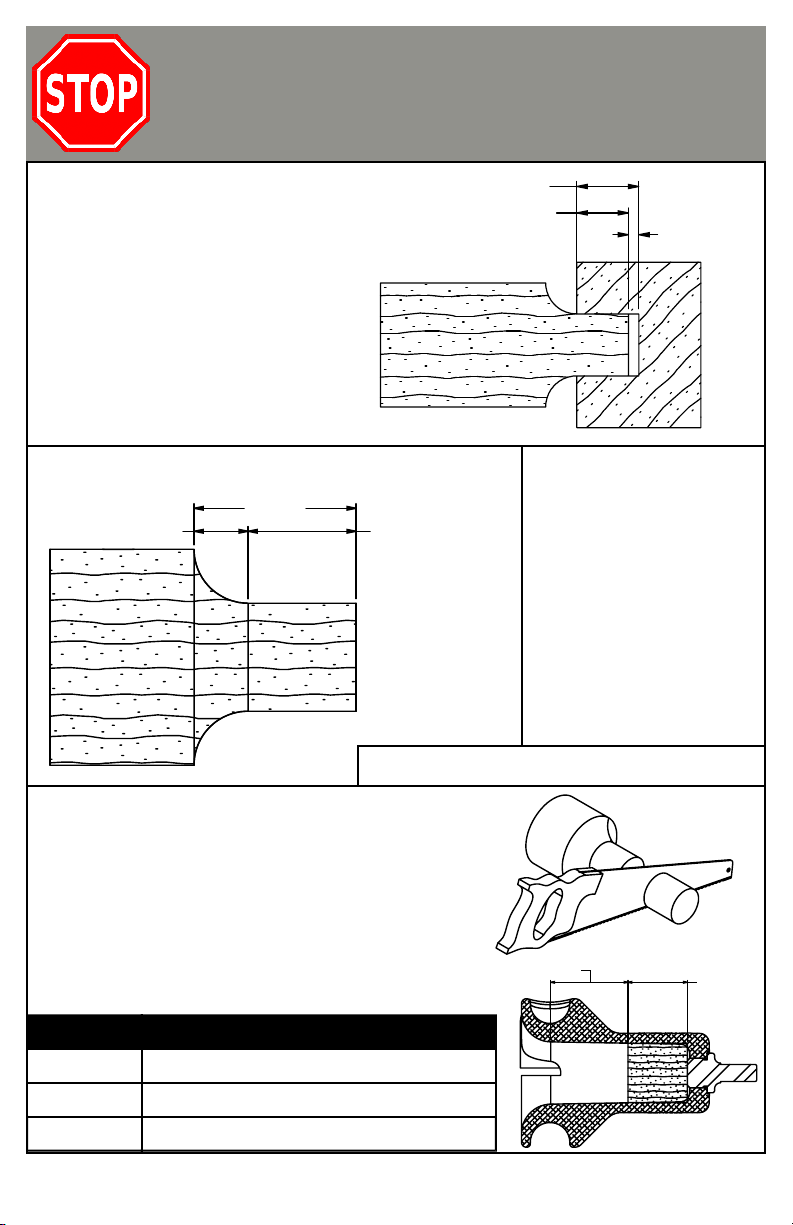

SettingtheBlades

●Install and secure

the blades with the

Button Head Cap

Screws

●Take your time and

make sure blade

offset/spacing is

equal (see below)

Cardboard

Spacer

BladeOffset (Spacing)

MaxLog

Capacity

Series MaxDia.

TTR0500

2.00”

TTR0750

2.25”

TTR1000

2.50”

TTR1500

3.00”

TTR2000

3.50”

TRH1000

2.50”

TRH1500

3.00”

TRH2000

3.50”

●The cardboard box that the tool

comes in is about 3/16”

●Remove a piece of thebox to use

as a quick spacer for blade

setting

Tip

It is critical that both blades have the same “offset”. Blade offset refers to

the gap size between the blade cutting edge and the side of the pocket.

3/16” is the standard gap size to use.

●The tool will not cut with 5/16” or greater spacing

●The tool will not cut with 1/16” or less spacing

Correct (Blade too far)

WRONG

(Blade too close)

WRONG

6

Determine tenon length before cutting

●The key is to have a gap

between the end of the

tenon and bottom of the

mortise hole

●This can be done by making

the tenon 1/8” to 1/4”

shorter than the mortise

hole is deep

Hole Depth

1/8” to 1/4”

Gap

Tenon Length

Calculated Tenon Length

Simple Tenon Length

●Tenon length can be controlled without

having the Industrial Series or Quick

Stop Pins

●Cut off a piece of tenon to use as a plug

to stop cutting at a set length

Cut Mark = desired tenon length + 3/4”

Gather the following

information and use the

calculation provided

below:

●Desired tenon

length

Cut Mark

3/4" Desired Tenon Length

Series TenonLength

TRH1000

2½”–PlugLength

TRH1500

3½”–PlugLength

TRH2000

4½”–PlugLength

Plug Length

Tenon Length

7

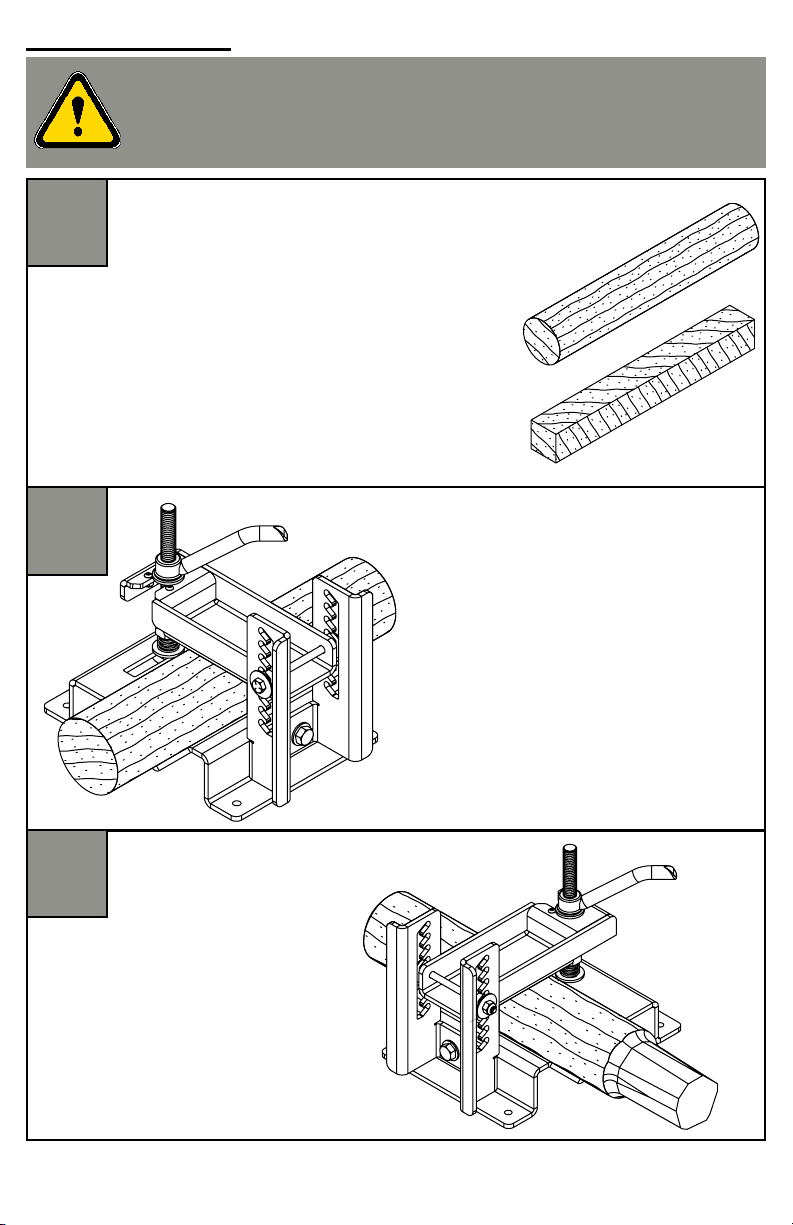

CuttingTenons

●Secure the stock in a vise, clamp,

or fixture with a “V” shaped

notch

●The Log Lock (LL1545) is a safe,

easy, economical way to clamp

material, and is available on our

website

WARNING: If the stock comes loose or unclamped while cutting, DO NOT

drop the drill or try to grab the stock! Stop cutting and remove the tool

from the end of the stock. Re-secure the stock, and resume cutting

●Obtain the stock you want to cut

●Check that the diameter fits the tool capacity

●Cut stock to length and make sure the ends

are flat. If the ends are not even/flat, the

tenon will be crooked

●If the diameter is larger

than the tool can accept,

taper the end with a

hatchet or draw knife

1

2

3

8

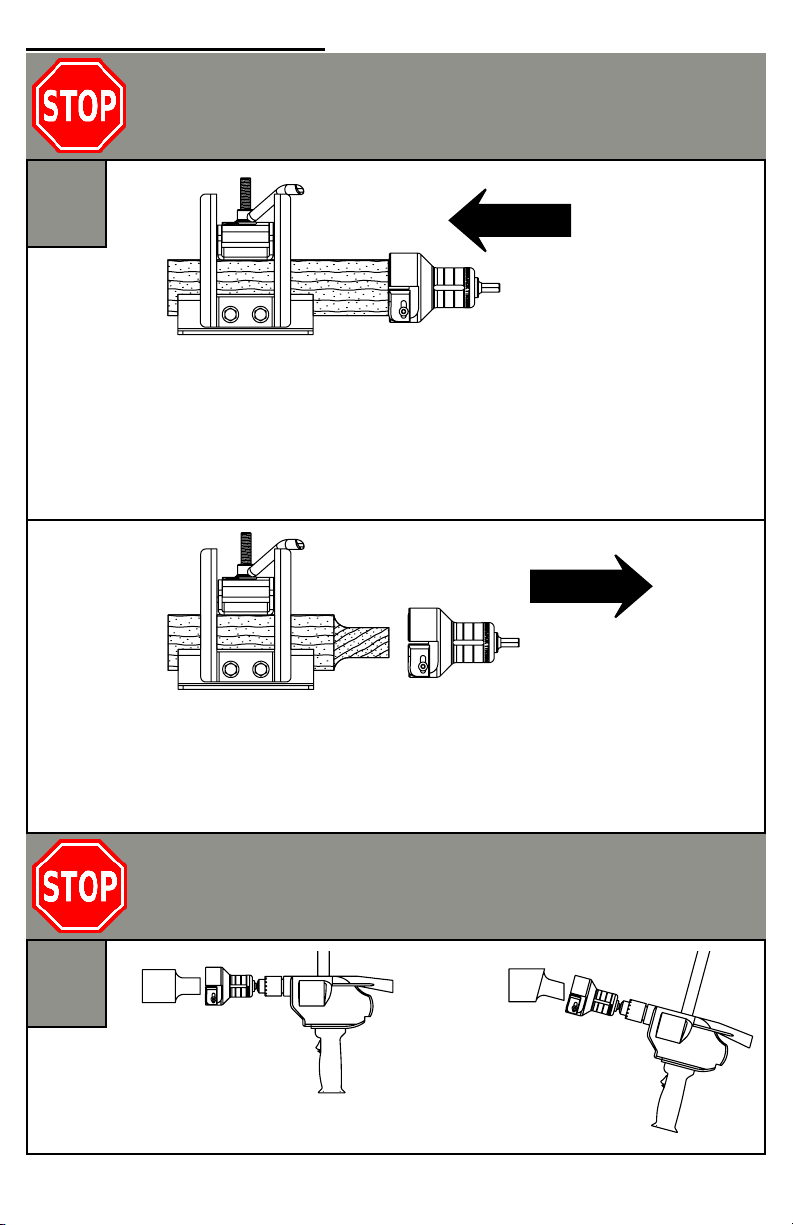

CuttingTenons(cont.)

ALWAYS unplug the drill before adjusting the blades or

adjusting the chuck

4.5

CORRECT

Drill in-line with log

WRONG

Drill not in-line with log (crooked)

●Make sure the tool is square against the end of the stock

before cutting

●If the tool is held at an angle the tenon will be cut angled

Maintain

constant

pressure

Pull tool back once

drill has stopped

4

●Carefully install the tenon cutter into an unplugged 1/2” drill, and

tighten it firmly by using the chuck key

●With the tool installed, square up to the stock so that the cutting face is

flush with the end of the stock

●Apply body pressure by leaning against the back of the drill

●Pull drill trigger to cut a tenon. Continue applying body pressure as the

tool cuts

●Wait until the drill comes to a complete stop before removing the tool

from the stock

9

Tip

Measure and mark the locations of all holes before drilling

DrillingHoles(Mortise)

1

2

●Drill mortise between

1/3 and 1/2 of the log

diameter

●Do not drill more than

1/2 of the log diameter

unless a specific project

calls for a deeper mortise

1/2 Diameter

1/3 Diameter

●Place the center of the bit on the

desired hole location

●Hold the drill perpendicular to the log

(unless angled holes are desired)

●Maintain constant pressure while

drilling down

●Pull drill bit out in a controlled manner

We recommend using a forstner bit or self-feeding bit to drill the hole.

Spade/paddle bits will work but cut rough

10

Maintenance

●Body

- Cleaning

○ Keep the tenon cutter body clear of sap and other build-up

○ Always remove the blades before cleaning

○ Clean the tool with a solvent (such as mineral spirits)

●Blades

- Care

○ Always wipe blades with a thin film of oil at the end of the day

to help prevent oxidation

- Cleaning

○ Clean the blades with a solvent (such as mineral spirits) and

immediately apply a thin film of oil to prevent oxidation

- Sharpening

○ Use a sharpening stone, file or the Blade Boss (BB2575) to re-

sharpen the blades, then clean the blades and apply a thin film

of oil

●Shank

- Replacement

○ If your shank breaks, we offer replacement shanks (see first

page for contact information)

○ Turn the shank counter-clockwise to remove

○ Turn the shank clockwise to install

WARNING: ALWAYS HANDLE THE BLADES WITH EXTREME CARE!

FAILURE TO DO SO MAY RESULT IN SERIOUS INJURY

TASK EACH USE MONTHLY

Clean blade pockets X

Clean cutter bore X

Clean blades X

Inspect blades X

Oil blades X

Oil shank & screws X

Visit our website or call

for more information

about our Blade Boss

Other manuals for PRO Series

1

This manual suits for next models

9

Table of contents

Popular Cutter manuals by other brands

Milwaukee

Milwaukee HEAVY DUTY M12 FCOT Original instructions

SignWarehouse.com

SignWarehouse.com Bobcat BA-60 user manual

Makita

Makita 4112HS instruction manual

GEISMAR STUMEC

GEISMAR STUMEC MTZ 350S manual

Hitachi

Hitachi CM 4SB2 Safety instructions and instruction manual

Dexter Laundry

Dexter Laundry 800ETC1-20030.1 instruction manual