Remarks concerning the operator safety:

1. General

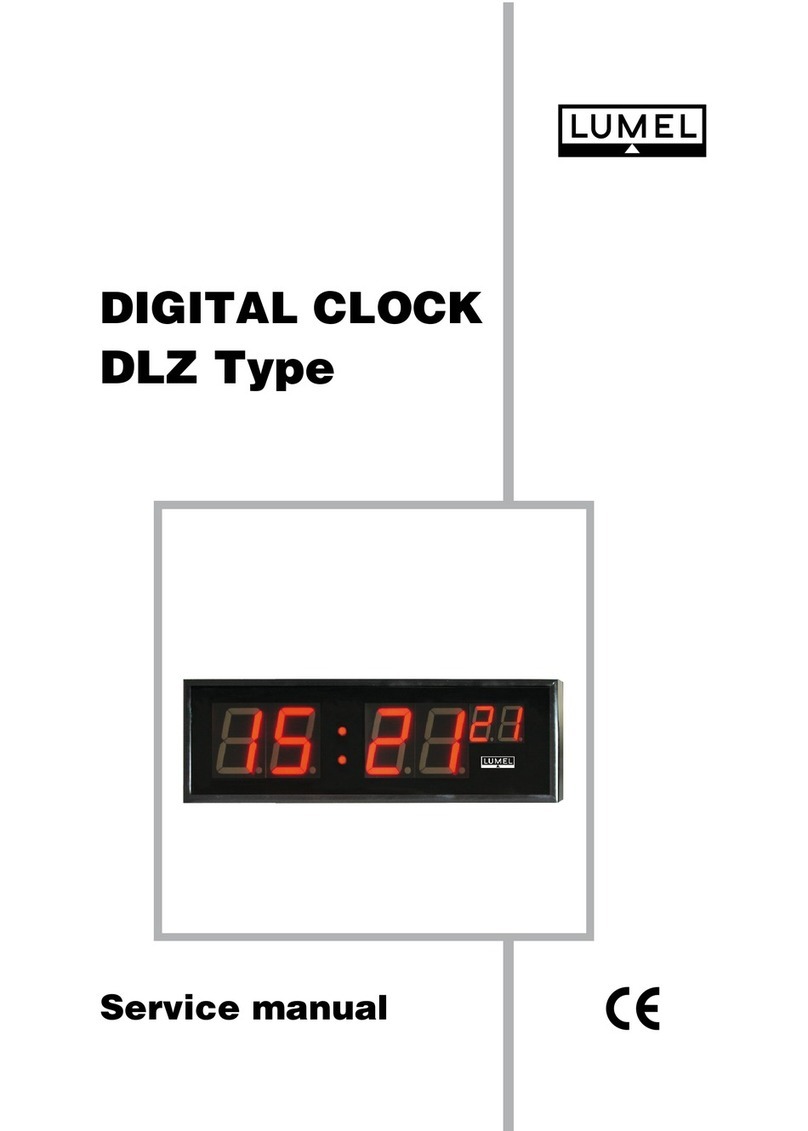

nThe digital clock is destined to be installed inside or outside buildings.

nNon-authorized removal of the required housing, inappropriate use, incorrect installation or opera-

tion create the risk of injury to personnel or damage to equipment. For more detailed information

please study the user’s manual.

nAll operations concerning transport, installation, and commissioning as well as maintenance must be

carried out by qualified, skilled personnel and national regulations for the prevention of accidents

must be observed.

nAccording to this basic safety information, qualified, skilled personnel are persons who are familiar

with the installation, assembly, commissioning, and operation of the product and who have qualifi-

cations necessary for their occupation.

2. Transport, storage

Please observe the notes on transport, storage and appropriate handling.

Observe the climatic conditions given in Technical Data.

3. Installation

nThe DZ digital clock must be installed according to the regulation and instructions given in this user’s

manual.

nEnsure proper handling and avoid mechanical stress.

nDo not bend any components and do not change any insulation distances.

nDo not touch any electronic components and contacts.

nElectronic devices may contain electrostatically sensitive components, which can easily be dama-

ged by inappropriate handling.

nDo not damage or destroy any electrical components since this might endanger your health!

4. Electrical connection

nBefore switching the digital clock on, one must check the correctness of connection to the network.

nIn case of the protection terminal connection with a separate lead one must remember to connect it

before the connection of the digital clock to the mains.

nWhen working on live instruments or devices, the applicable national regulations for the prevention

of accidents must be observed.

nThe electrical installation must be carried out according to the appropriate regulations (cable cross-

sections, fuses, PE connection). Additional information can be obtained from the user’s manual.

nDo not connect the digital clock to the mains via an autotransformer.

nThe documentation contains information about installation in compliance with EMC (shielding, groun-

ding, filters and cables). These notes must be observed for all CE-marked products.

nThe manufacturer of the installation or installed auxiliary devices is responsible for the compliance

with the required limit values demanded by the EMC legislation.

nThe RS-485 socket serves only for the connection of digital clocks operating with the MODBUS

protocol.

5. Operation

nInstallations including DZ2 or DZ3 digital clocks must be equipped with protection devices accor-

ding to the corresponding standard and regulations for prevention of accidents.

nAfter the digital clock has been disconnected from the supply voltage, live components and power

connections must not be touched immediately because capacitors can be charged.

nThe housing must be closed during operation.