www.luminator.com Page 2

TABLE OF CONTENTS

1INTRODUCTION.......................................................................................................................................................3

1.1 Overview............................................................................................................................................................ 3

1.2 Disclaimer ......................................................................................................................................................... 3

1.3 Warranty, Service and Support Information .................................................................................................... 3

1.4 Safety Notes...................................................................................................................................................... 3

1.5 System Components and Accessories ........................................................................................................... 3

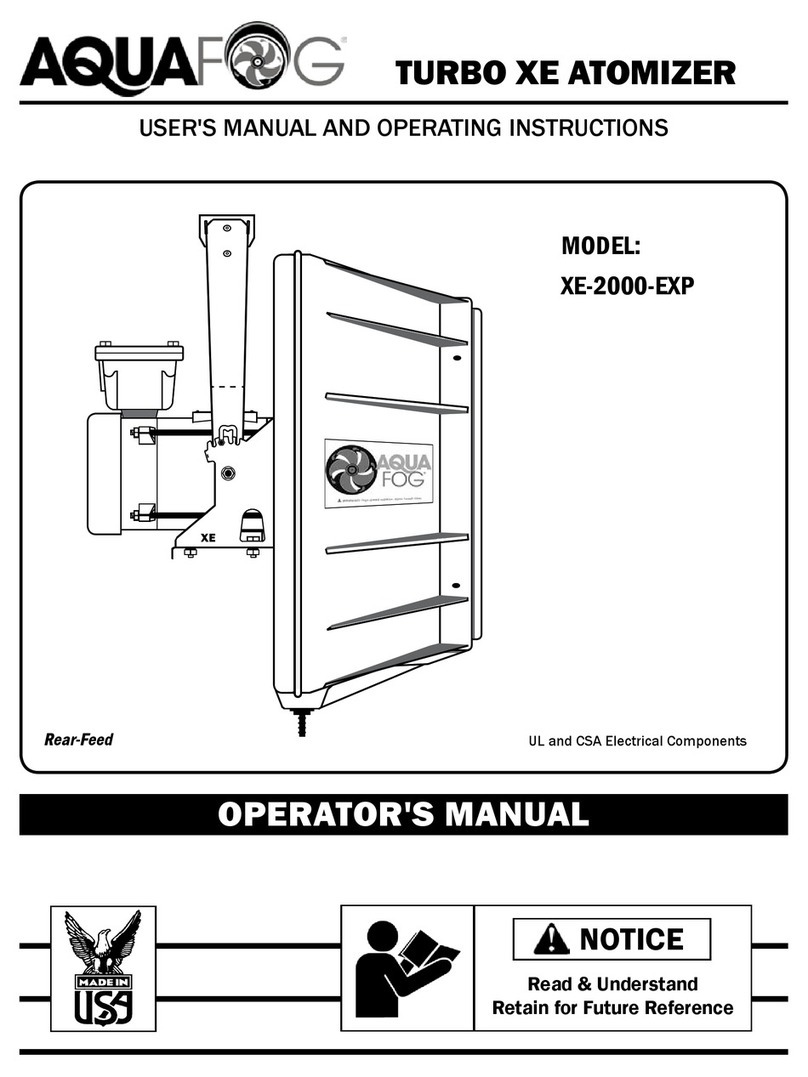

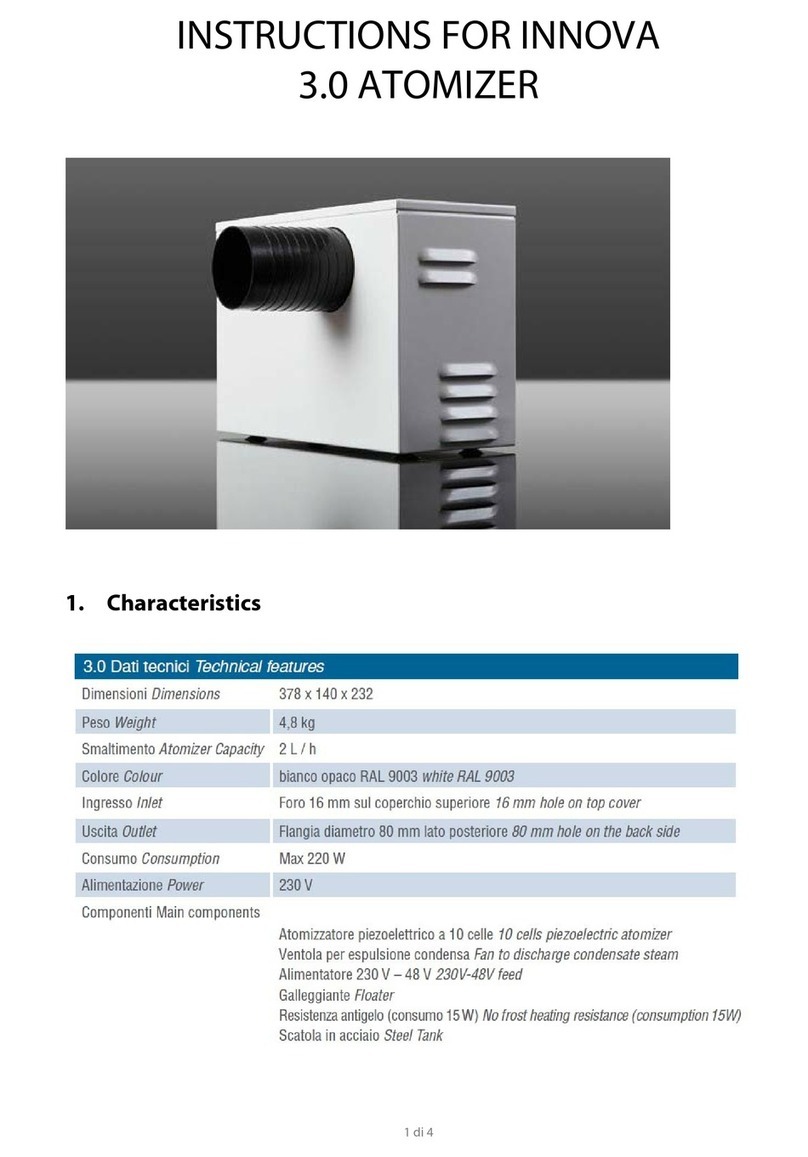

2System Atomizer.....................................................................................................................................................4

2.1 Introduction....................................................................................................................................................... 4

2.2 Power................................................................................................................................................................. 4

2.3 Mounting ........................................................................................................................................................... 4

2.4 Mounting Illustrations ...................................................................................................................................... 4

2.5 Connections ...................................................................................................................................................... 5

3System Controller....................................................................................................................................................6

3.1 Introduction....................................................................................................................................................... 6

3.2Power................................................................................................................................................................. 6

3.3 Mounting ........................................................................................................................................................... 6

3.4 Connections ...................................................................................................................................................... 6

3.5 Configuration Settings...................................................................................................................................... 8

4System Sensor ........................................................................................................................................................9

4.1 Introduction....................................................................................................................................................... 9

4.2 Power................................................................................................................................................................. 9

4.3 Mounting ........................................................................................................................................................... 9

4.4 Connections ...................................................................................................................................................... 9

5Initial System Setup...............................................................................................................................................10

5.1 Install the Atomizer......................................................................................................................................... 10

5.2 Install the Controller ....................................................................................................................................... 10

5.3 Install the Sensor ............................................................................................................................................ 10

5.4 Activate the Atomizer ..................................................................................................................................... 10

5.5 Activate the Controller.................................................................................................................................... 11

6Renew System Application....................................................................................................................................12

6.1 Introduction..................................................................................................................................................... 12

6.2 Accessing the Application.............................................................................................................................. 13

6.3 Controller Status ............................................................................................................................................. 13

6.4 Controller Configuration................................................................................................................................. 14

6.5 Controller Software Upgrade ......................................................................................................................... 15

6.6 Controller Date and Time Settings................................................................................................................. 16

APPENDIX ...................................................................................................................................................................17

Configure a Static IP Address........................................................................................................................................ 17

Copyright 2020 Luminator Technology Group, Inc.

The information contained in this document is proprietary to Luminator Technology Group, Inc., and shall not be used or reproduced for any purpose

without prior written consent.