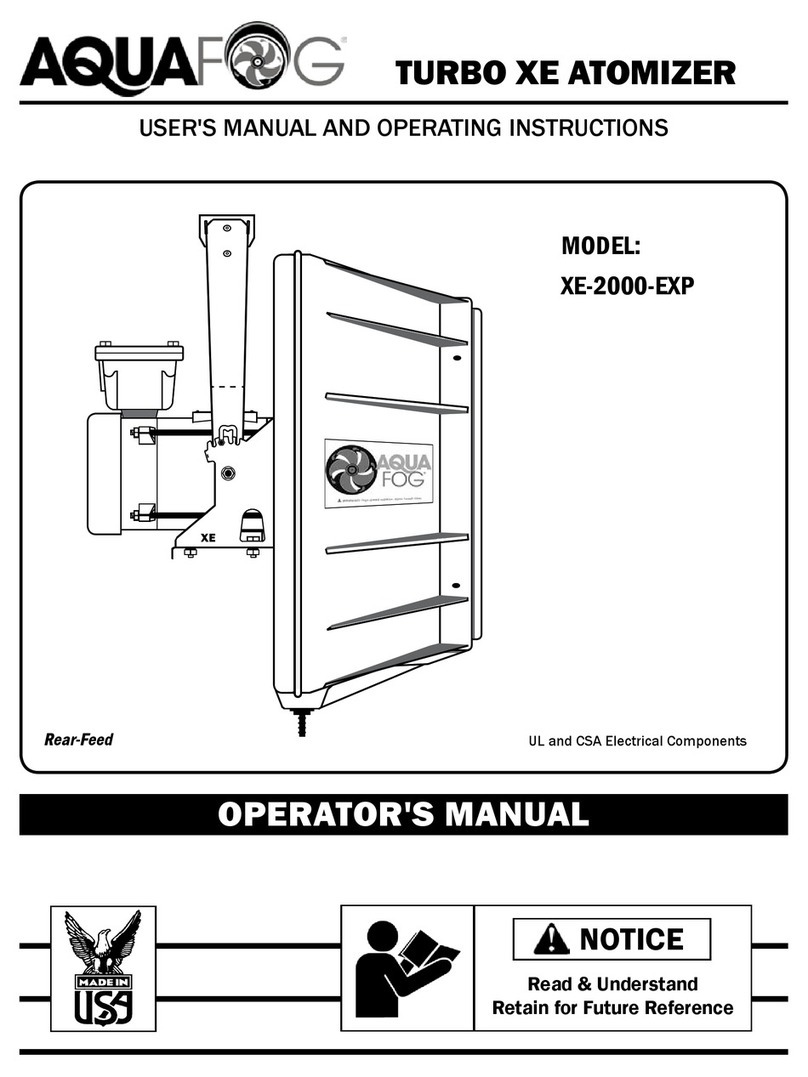

GENERAL INFORMATION

The ultrasonic power supply converts 50/60 Hz line voltage to high frequency electrical

energy at 20 kHz or 40 kHz (20,000 or 40,000 cycles per seconds), depending on the

model. This high frequency electrical energy is transmitted to the piezoelectric transducer

within the converter, where it is changed to mechanical vibrations. The ultrasonic

vibrations are intensified by the probe and focused at the tip where the atomization takes

place. The liquid travels through the probe, and spreads out as a thin film on the

atomizing surface. The oscillating tip disintegrates the liquid into micro-droplets, and

ejects them to form a gentle, low velocity spray.

Unlike conventional atomizing nozzles that rely on pressure and high-velocity motion to

shear a fluid into small drops, the ultrasonic atomizer uses only low ultrasonic vibrational

energy for atomization. The liquid can be dispensed to the atomizing probe (nozzle) by

either gravity or a small low-pressure metering pump, and atomize continuously or

intermittently. The rate at which the liquid is atomized depends, within limits, solely on

the volume that is being delivered onto the atomizing surface, and the frequency. The

amount of material atomized can be as little as 2 µl/sec. Because the droplets typically

drift downward at low velocity under the influence of gravity, the probe should be

mounted with tip facing downward, and air disturbances kept to a minimum. A wide

variety of coatings, chemicals, lubricants, and particulate suspensions can readily be

atomized. However, factors such as viscosity, miscibility, and solid content deserve

consideration. For optimum atomization, the viscosity should be under 500 cps and the

solid concentration kept below 30%. Because the atomization process depends on setting

a liquid film into motion, typically the higher the viscosity – the lower the flow rate, and

the more difficult the application. The atomization of liquids containing long-chained

polymer molecules is problematic, even in diluted form, due to the highly cohesive nature

of the material. In many cases, mixtures with particulates can be atomized, because the

solids are simply carried along in the drops. The low transport velocity of the liquid

through the probe permits even abrasive slurries to be processed with negligible erosion

of the passageway. Compared with conventional pressurized nozzles, the feed channel

running through the probe and exit orifice are relatively large, and practically

uncloggable. Drop size is primarily a function of frequency, and the higher the frequency,

the smaller the drop diameter. The median drop size at 40 kHz is 50 microns.

Atomizing probes are one-half wavelength long tools that act as mechanical transformers

to increase the amplitude of vibration generated by the converter. They are fabricated

from high grade titanium alloy Ti-6Al-4V because of its high tensile strength, good

acoustical properties at ultrasonic frequencies, high resistance to corrosion, low toxicity,

and excellent resistance to cavitation erosion.