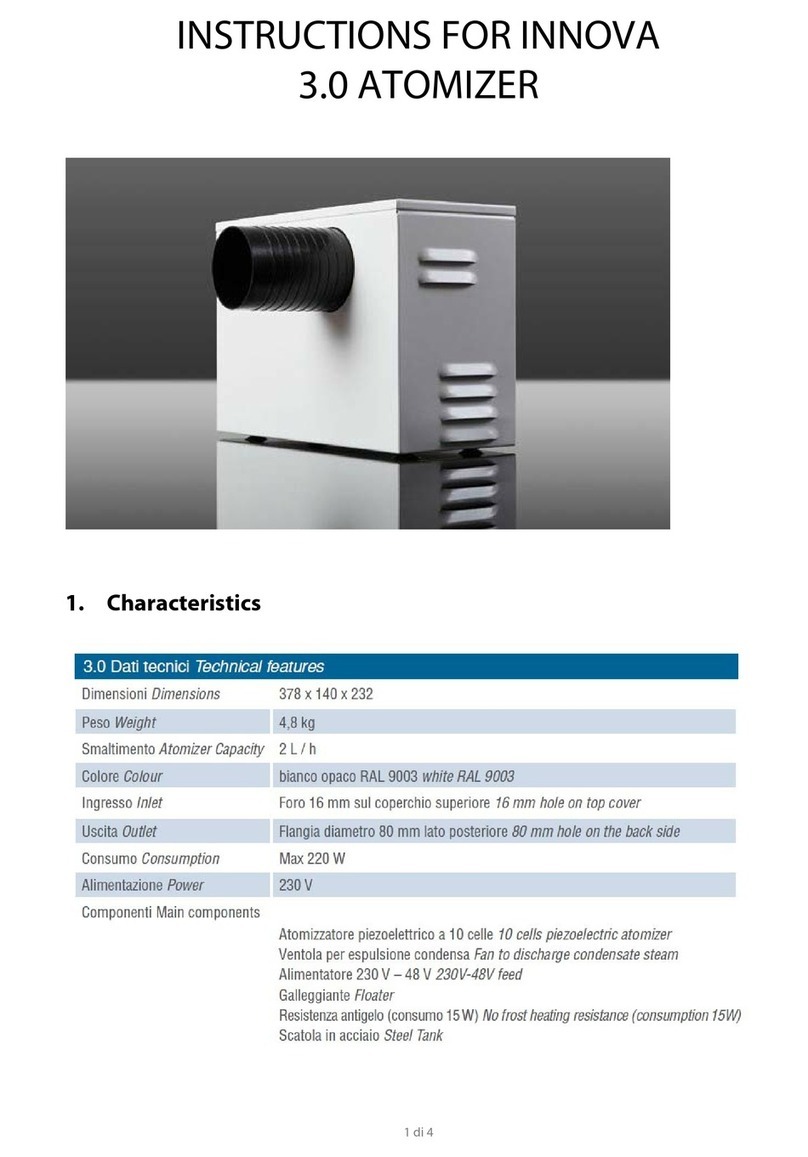

MU-iCAT-1120 iCAT 7 - 40

The service rules described in this manual are an integral part of the supply of the Air Sprayer.

These rules are, moreover, designed for an operator already expressly trained to use this type of machine, and contain all the

information necessary and essential for the operational safety and optimal use of the Air Sprayer.

Hurried preparations cause improvisation and this is a cause of many accidents.

Before starting work, carefully read and thoroughly observe the following tips:

- familiarise yourself, before you begin to operate the Atomizer, with any acceptable operation and position;

- the operator should always have the Instruction Manual at his/her disposal;

- schedule each task with care;

- obtain all the necessary information for the road transport of the Atomizer.

- know in detail where and how the use of the Atomizer is required;

- make sure you always have at your disposal the necessary equipment;

- before beginning work, make secure that the safety devices work correctly; moreover, be certain about their functioning,

otherwise do not to use the machine under any circumstances;

- carry out mixtures change properly and safely;

- constant and accurate preventive maintenance always guarantees the machine a high level of operational safety.

Never put off the necessary operations, and ensure they are performed exclusively by specialised personnel, using only original

spare parts.

Terminology:

Mixture: product, diluted or not, containing biocides, plant protection products, pesticides, disinfestation products, deodorization

products and/or any product used for treatments performed with this machine.

TIFONE AMBIENTE s.r.l. guarantees its machines from any defect in design, manufacturing or materials used, which may become

manifest within 12 months from delivery of the Atomizer.

The customer must notice TIFONE AMBIENTE s.r.l. about vices and/or defects detected within 8 days from detection, in writing,

otherwise the warranty shall be void.

The guarantee applies only to the vices and defects that occur in the conditions of correct use of the Atomizer, following the

instructions in this Manual and carrying out the planned periodic maintenance.

Failures arising from improper use of the Atomizer, atmospheric agents, damage caused by transport, are expressly excluded from

warranty.

All consumables and regular maintenance materials are not covered under the warranty and their costs are entirely borne by the

customer; in each case, the warranty is automatically voided wherever the Atomizer has suffered tampering or interventions by

technicians not authorized by TIFONE AMBIENTE s.r.l..

The warranty is voided when:

- the oil level of the pump is not regularly checked;

- the pump is not stopped immediately in the event of breakage of the membranes;

The following is not covered by warranty:

- damage caused by frost to the pump and/or to other parts;

- damage due to failure to thoroughly clean the main circuit each time the Air Sprayer is used;

- damage caused by an excess of pressure of the circuit.

- damage caused by any improper use of the atomizer.

WARNING: The materials provided by the company TIFONE AMBIENTE s.r.l. are covered by a guarantee of 12

months from the date of commissioning, proven by the delivery note to the customer.

The company TIFONE AMBIENTE s.r.l. reserves the right to repair or replace, during the warranty period, the

parts recognized as being faulty.

With the replacement of the part considered defective, TIFONE AMBIENTE s.r.l. shall be free from any other

expenses incurred by the Dealer and by the Customer of the Dealer as perceived damage (present or future),

including loss of earnings, conventional penalty, etc...

Ordinary and extraordinary maintenance must be performed in accordance with the instructions contained in

this Manual.

In all cases not included and for any kind of assistance, it is recommended that you contact directly TIFONE

AMBIENTE s.r.l. via registered mail or by fax, even in the case of agreements made by phone.

TIFONE AMBIENTE s.r.l. shall not be liable for any delays or non-action.

TIFONE AMBIENTE s.r.l. shall not be liable for any damages or malfunctions due to technical interventions

performed on the machine by unauthorized personnel.

DANGER: Use by persons under 18 years of age is prohibited.

1.3 INTRODUCTION

1.4 WARRANTY