10

EvacSkate 14

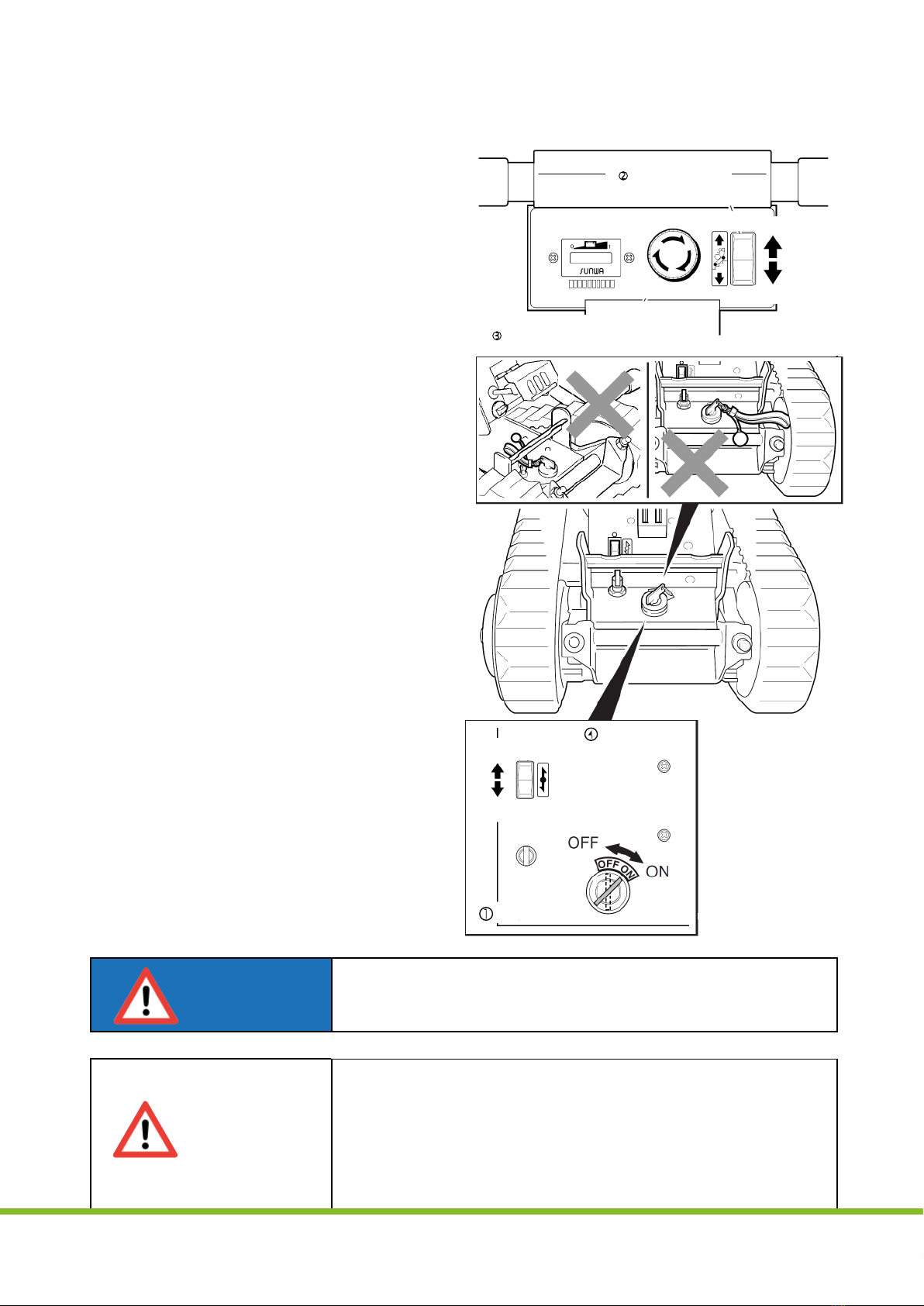

5. DESCRIPTION OF EACH UNIT

5.1 SWITCHES

1. Key Switch

It turns on/off the power supply. When it is

turned clockwise, the power will be ON and

when turned counter-clockwise, the power

will be off.

NOTE: When STAIRMATE is not to be used

(to be stored, to be charged, to be

transported), turn off Key Switch,

remove Key and keep it in an

appointed place.

2. UP/DOWN Switch

Selects ascent or descent mode. Only while

this Switch is pressed, does the machine

run. If UP Seesaw is pressed, the machine

will ascend. If DOWN Seesaw is pressed,

the machine will descend.When the finger is

released, Switch will automatically return its

neutral position and the machine will stop.

3. Emergency Stop Switch

When this Switch is pressed, the machine

will stop immediately. STAIRMATE won‘t

restart. Even when the other Switch is

pressed.Torelease the emergency stop

condition, turn Emergency Stop Switch in

the „arrow“ indicated direction.

4. Operation Switch on Drive Unit

When Forward or Reverse Switch top

is pressed, the machine will run in the

corresponding direction. When Switch

is released, Switch will return its neutral

position and the machine will stop.

NOTE: This Switch is not to be used for

stair work. Use it only for running

STAIRMATE without Handle Unit.

UP/DOWNSwitch

Ascending

Descending

Emergency Stop Switch

Operation Switch

on Drive Unit

Forward

reverse

Key Switch

Never attach the objects to Key.If any object is attached to Key,

it will be caught in Lock Unit preventing Frame from locking.

This could result in a serious accident

DANGER

• If Key Switch is kept in the ON position, Battery will more

quickly discharge.When the machine is not to be in use, be

sure to turn off Key Switch and remove it.

• Never attach the objects to Key. Doing so may cause the

objects to be caught by Rubber Crawler.

• Pay attention that the operator‘s fingers are not caught in a

Rubber Crawler while the operator pushes Operation Switch

on Drive Uint near floor level.

CAUTION

5. DESCIPTION OF EACH UNIT

10

5. DESCIPTION OF EACH UNIT

10