M-D Pneumatics COMPETITOR PLUS 2002 User manual

LEADING THE SEARCH FOR NEW SOLUTIONS

4840 West KearneyStreet, P. O. Box 2877

Springfield, Missouri USA 65801-2877

Tel 417 865-8715 800 825-6937 Fax417 865-2950

www.mdpneumatics.com

Rotary Positive Blowers

COMPETITOR PLUS rotar

y

blowers are desi

g

ned to be

interchan

g

eable with e

q

uivalent sizes of Roots Universal

RAI®, and man

y

Sutorbilt® California Series B and F, and

Le

g

end™ Series L and P blowers. COMPETITOR PLUS

models are rated up to 15 PSIG dischar

g

e pressure or 16” H

g

dr

y

vacuum.

In addition to interchan

g

eabilit

y

, M-D has improved on

existin

g

desi

g

ns with the followin

g

superior features ordinaril

y

found onl

y

on premium blowers:

Helical Gearing

COMPETITOR PLUS blowers are timed with hardened,

precision helical

g

ears, ke

y

ed to the rotor shafts, not taper fit

spur

g

ears offered b

y

other manufacturers which have

g

reater

backlash, and can slip and lose timin

g

. Helical

g

ears are also

q

uieter, reducin

g

mechanical noise.

Stronger Bearings

COMPETITOR PLUS blowers include double row ball

bearin

g

s at the

g

ear end, stron

g

er than sin

g

le row ball

bearin

g

s offered b

y

other manufacturers. Drive shaft bearin

g

is c

y

lindrical roller t

y

pe for additional stren

g

th a

g

ainst side

loadin

g

from V-belt drives. As a result of this superior desi

g

n,

COMPETITOR PLUS blowers offer an avera

g

e desi

g

n

bearin

g

life of up to 50%

g

reater than models offered b

y

other

manufacturers.

Rotors with Integral Shafts

COMPETITOR PLUS blowers include precision machined

ductile iron rotors with lar

g

e, inte

g

rall

y

cast shafts, not press

fit and/or pinned shafts offered b

y

other manufacturers, which

can loosen over time and cause rotor clash. All rotors are

d

y

namicall

y

balanced for vibration-free rotation.

Positive End Clearances

End clearances are positivel

y

established at the blower

g

ear

end, eliminatin

g

the risk of shiftin

g

end clearances when

installin

g

or removin

g

drive components. This also eliminates

the need for those special fork and saddle tools re

q

uired b

y

other brands to reset end clearances.

Polished Sealing Surfaces

All shaft surfaces in contact with sealin

g

members are

polished to reduce seal wear and risk of leaka

g

e.

Individually Tested

Ever

y

COMPETITOR PLUS blower is factor

y

tested to assure

y

ou of the hi

g

hest

q

ualit

y

. While some manufacturers perform

onl

y

sample testin

g

, M-D

g

oes the distance to insure that

y

our

blower meets our ri

g

id ISO 9001 re

g

istered

q

ualit

y

standards.

ISO 9001 Registration

COMPETITOR PLUS blowers are manufactured under M-D’s

ISO 9001 re

g

istered

q

ualit

y

assurance pro

g

ram, the first

American manufacturer of rotar

y

blowers to

g

ain such

international reco

g

nition.

Warranty

Ever

y

COMPETITOR PLUS blower is backed b

y

M-D’s limited

warrant

y

for a period of 18 months after installation or 2

y

ears

after ori

g

inal blower shipment, whichever occurs first.

Versatility

COMPETITOR PLUS blowers can be field converted from

horizontal to vertical flow, or vice versa, without an

y

special

tools or

additional components.

Metric Availability

All COMPETITOR PLUS blowers are available with metric drive

shaft and process connections.

Worldwide Sales and Service

With sales offices and service facilities located on six continents,

y

ou can be assured of availabilit

y

and service for

y

our

COMPETITOR PLUS blowers.

Material Specifications:

Housin

g

: Cast iron

End Plates: Cast iron

End Cover: Cast iron

Rotors: Ductile iron

Shafts: Ductile iron cast inte

g

rall

y

with rotors

Bearin

g

s: Gear end - Double row ball, both rotors

Drive end - C

y

lindrical roller on drive rotor

Sin

g

le row ball on driven rotor

Drive Shaft: Ductile iron, cast inte

g

rall

y

with drive rotor

Gears: Heat treated allo

y

steel, helical cut

Seals: Lip seals on rotor shafts and drive shaft

Lubrication: Oil splash on

g

ear end,

g

rease on drive end

Model

Size Max.

Press.

PSI

Max.

Vac.

(in. Hg)

Nominal Min.

RPM @ Max.

Disch. Press.

Nominal Max.

RPM @ Max.

Disch. Press.

Displ.

CFR

2002 12 16 2940 5275 .016

2004 7 14 1480 5275 .032

3003 12 15 2080 3600 .0616

3006 7 12 1150 3600 .102

4002 15 16 1820 3600 .061

4005 10 14 1300 3600 .121

4007 7 14 1000 3600 .160

5003 15 16 1900 2850 .132

5006 10 15 980 2850 .221

5009 7 14 700 2850 .323

6005 15 16 1240 2350 .246

6008 12 16 890 2350 .395

6015 6 12 600 2350 .740

Blower SPEED 2 PSIG 4 PSIG 6 PSIG 7 PSIG 10 PSIG 12 PSIG 15 PSIG Max. Vacuum

Model (RPM) CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP “ Hg CFM BHP

2002 1170

3600

5275

7

46

73

0.3

0.8

1.2 41

68 1.3

1.9 38

64 1.8

2.7 36

63 2.1

3.1 32

59 2.8

4.2 29

56 3.3

4.9

6

14

16

3

28

51

0.3

2.1

3.4

2004 1170

3600

5275

19

97

150

0.4

1.3

1.9

12

89

143

0.8

2.3

3.4 83

137 3.3

4.9 81

134 3.8

5.6

6

14

14

13

69

122

0.6

3.8

5.5

3003 1170

2700

3600

49

143

198

0.8

1.9

2.5

39

133

188

1.4

3.3

4.5

31

126

181

2.1

4.8

6.4

28

122

178

2.4

5.5

7.4 114

169 7.7

10 109

164 9.1

12

10

14

15

27

107

158

1.7

5.4

7.7

3006 1170

2700

3600

86

242

334

1.2

2.8

3.8

72

228

320

2.3

5.2

7.0

62

218

310

3.3

7.6

10

57

213

305

3.8

8.9

12

10

12

14

56

202

283

2.7

7.5

12

4002 880

1760

3600

34

87

198

0.6

1.3

2.6

26

79

190

1.1

2.2

4.5

19

73

184

1.6

3.1

6.4

17

70

181

1.8

3.6

7.4 63

174 5.0

10 59

170 5.9

12 164 15

10

14

16

16

57

159

1.3

3.5

8.2

4005 880

1760

3600

70

177

399

1.1

2.2

4.5

55

162

384

2.0

4.1

8.3

44

150

373

3.0

5.9

12

39

145

368

3.4

6.9

14 132

355 9.6

20

8

13

14

47

127

349

2.0

63

13

4007 880

1760

3600

93

234

527

1.4

2.8

5.7

74

214

508

2.6

5.3

11

59

199

493

3.9

7.7

16

52

193

486

4.5

8.9

18

8

12

14

63

176

472

2.6

7.6

18

5003 710

1760

2850

64

203

346

1.0

2.6

4.1

52

191

334

1.6

4.6

7.4

43

181

325

2.7

6.6

11

39

177

321

3.1

7.6

12 167

310 11

17 160

304 13

21 152

295 16

25

10

14

16

37

158

289

2.2

7.5

14

5006 710

1760

2850

108

340

581

1.6

3.9

6.4

87

319

560

3.0

7.3

12

71

303

544

4.3

11

17

65

297

537

5.0

12

20 278

519 17

28

10

14

15

62

263

496

3.6

12

21

5009 710

1760

2850

173

513

865

2.2

5.5

8.9

151

490

842

4.2

10

17

133

472

824

6.2

15

25

125

464

816

7.2

18

29

10

12

14

122

445

779

5.1

15

28

6005 710

1760

2350

129

387

532

1.8

4.5

6.0

110

368

513

3.3

8.3

11

95

354

499

4.9

12

16

89

347

492

5.6

14

19

72

330

476

7.9

20

26 160

304 23

31 307

452 29

38

12

16

16

73

300

445

4.8

16

21

6008 710

1760

2350

207

621

854

2.7

6.8

9.1

176

591

824

5.2

13

17

153

568

801

7.6

19

25

143

557

790

8.9

22

29

116

530

764

13

31

41 515

748 37

50

12

16

16

117

481

714

7.5

25

33

6015 710

1760

2350

387

1164

1601

4.9

12

16

330

1107

1544

9.5

23

31

286

1063

1500

14

35

46

8

12

12

300

996

1433

9.3

34

46

Performance

Pressure performance is based on inlet conditions

of 14.70 PSIA and 70oF.

Vacuum performance is based on inlet temperature

of 70oF and discharge pressure of 14.70 PSIA.

In conjunction with our program of continuous

testing and upgrading, all specifications are subject

to change without notice.

All data are approximate. Request a quotation for

your specific application.

Your Local M-D Sales Professional is:

LEADING THE SEARCH FOR NEW SOLUTIONS

4840 West KearneyStreet, P. O. Box 2877

Springfield, Missouri USA 65801-2877

Tel 417 865-8715 800 825-6937 Fax417 865-2950

www.mdpneumatics.com

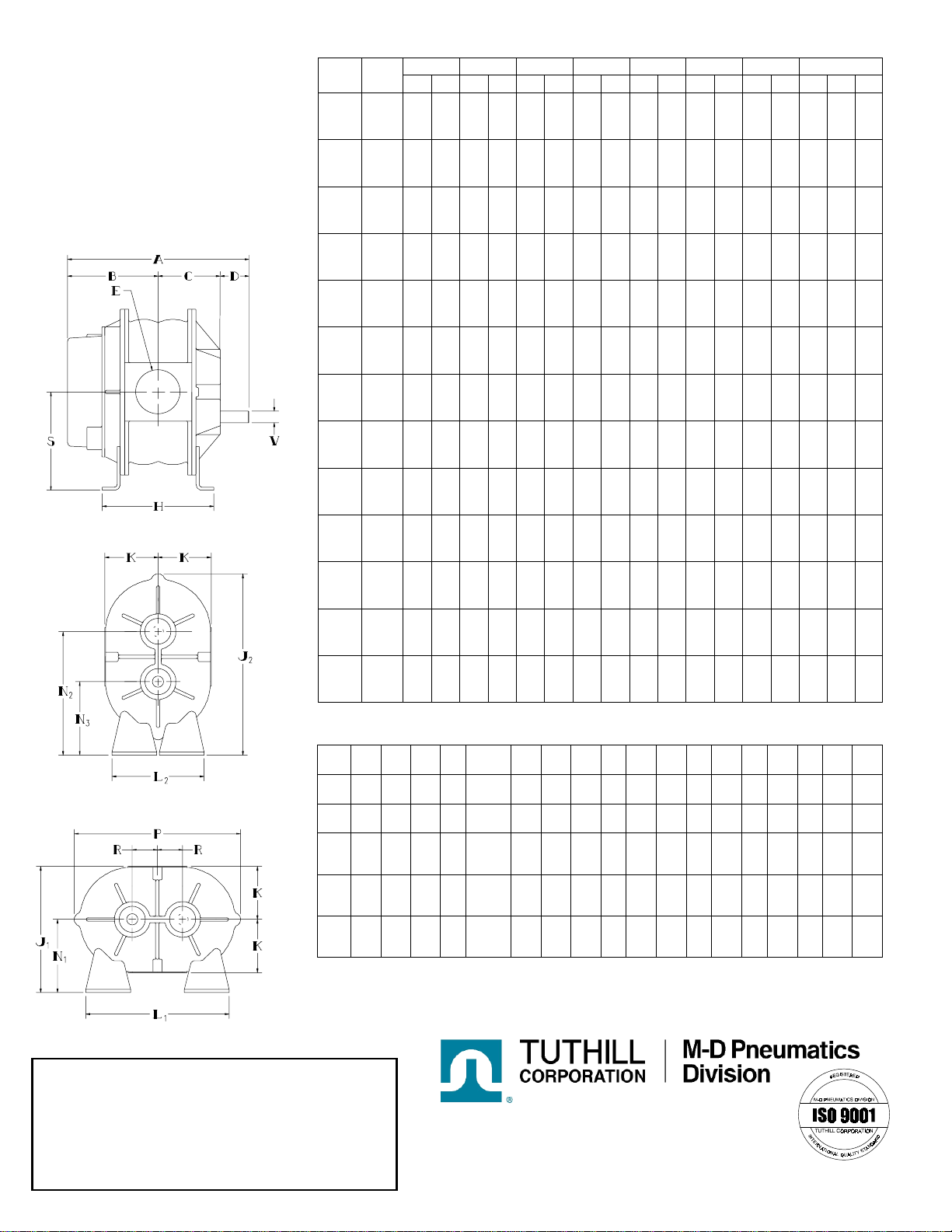

Model

Size A B C D E H J1 J2 K L1 L2 N1 N2 N3 P R S V

2002

2004 9.75

11.75 4.63

5.63 2.63

3.63 2.50 1” NPT

2” NPT 5.00

7.00 6.88 9.69 3.13 5.13 5.13 3.75 6.25 3.75 9.38 1.25 5.00 .625

3003

3006 12.19

14.56 5.94

7.13 3.75

4.94 2.50 2” NPT

2½” NPT 7.63

10.00 8.94 12.81 3.94 7.25 7.25 5.00 8.50 3.75 12.19 1.75 6.75 .750

4002

4005

4007

12.56

15.31

17.06

5.88

7.25

8.13

3.69

5.06

5.94 3.00 1½” NPT

2½” NPT

3” NPT

7.25

10.00

11.75 10.63 15.13 4.38 8.00 8.00 6.25 10.25 5.00 13.69 2.00 8.25 .875

5003

5006

5009

14.88

17.50

20.50

7.00

8.31

9.81

4.50

5.81

7.31 3.38 2½” NPT

4” NPT

4” NPT

8.38

11.00

14.00 12.13 17.38 5.38 10.50 10.50 6.75 11.25 6.25 17.19 2.50 8.75 1.125

6005

6008

6015

18.38

21.38

28.38

9.06

10.56

14.06

5.63

7.13

10.63 3.69 3” NPT

5” NPT

6” FLG

10.13

13.13

20.18 15.06 21.69 6.25 17.00 11.00 8.75 14.75 8.75 19.81 3.00 11.75 1.375

Dimensions

Values shown are approximate and should not be used for construction.

Certified drawin

g

s are available throu

g

h

y

our local M-D Sales Professional.

0899

Tuthill Pneumatics

Rotary Positive Displacement

Air Blower

2002 3003 4002 5003 6005

2004 3006 4005 5006 6008

4007 5009 6015

Models

INSTALLATION

OPERATION

MAINTENANCE

REPAIR

01/2001

WARNING

DO NOT OPERATE BEFORE

READING MANUAL.

LEADING THE SEARCH FOR NEW SOLUTIONS

4840 West Kearney Street, P. O. Box 2877

Springfield, Missouri USA 65801-2877

Tel 417 865-8715 800 825-6937 Fax 417 865-2950

E-mail: [email protected]

www.mdpneumatics.com

!WARNING

!WARNING

SAFETY INSTRUCTIONS

1. Do not operate before reading

the enclosed instruction manual.

2. Use adequate protection,

warning and safety equipment

necessary to protect against

hazards involved in installation

and operation of this equipment.

Do not operate

without guards

in place

Do not touch

hot surfaces

SAFETY WARNING

• Keep hands and clothing away from rotating machinery, inlet and discharge openings.

• Blower and drive mounting bolts must be secured.

• Drive belts and coupling guards must be in place.

• Noise level may require ear protection.

• Blower heat can cause burns if touched.

TUTHILL PNEUMATICS GROUP Springfield, MO USA

NOTICE

The above safety instruction tags were attached to your unit prior

to shipment. Do not remove, paint over or obscure in any manner.

Failure to heed these warnings could result in serious bodily injury

to the personnel operating and maintaining this equipment.

!WARNING

Keep body and

clothing away from

machine openings

Hearing

Protection

Required

!CAUTION

2

TABLE OF CONTENTS

SECTION PAGE

INTRODUCTION 4

OPERATING DATA 4

INSTALLATION 5

LUBRICATION 6

PREVENTATIVE MAINTENANCE 7

STARTUP CHECKLIST 7

TROUBLESHOOTING 8

RECOMMENDED SHUTDOWN PROCEDURE 9

DISASSEMBLY AND INSPECTION 10

BLOWER DISASSEMBLY 10

BLOWER ASSEMBLY 12

MAINTENANCE AND SERVICE SPECIFICATIONS SHEET 14

SPECIAL TOOL DRAWINGS 15

CUTAWAY VIEW AND PARTS LIST 16

WARRANTY STATEMENT 17

SAFETY PRECAUTIONS

For equipment covered specifically or indirectly in this instruction book, it is important that all personnel observe

safety precautions to minimize the chances of injury. Among many considerations, the following should particularly be

noted:

• Blower casing and associated piping or accessories may become hot enough to cause major skin burns on

contact.

• Internal and external rotating parts of the blower and driving equipment can produce serious physical injuries.

Do not reach into any opening in the blower while it is operating, or while subject to accidental starting. Cover

external moving parts with adequate guards.

• Disconnect power before doing any work, and avoid bypassing or rendering inoperative any safety or protective

devices.

• If blower is operated with piping disconnected, place a strong, coarse screen over the inlet and avoid standing

in discharge air stream.

• Avoid extended exposure in close proximity to machinery with high intensity noise levels.

• Use proper care and good procedures in handling, lifting, installing, operating, and maintaining the equipment.

• Other potential hazards to safety may also be associated with operation of this equipment. All personnel

working in or passing through the area should be warned by signs and trained to exercise adequate general

safety precautions.

• Hearing protection may be required depending on silencing capabilities.

CAUTION!

Most COMPETITOR PLUS™blowers are

shipped from the factory in a left hand drive,

vertical flow configuration.

If drive shaft location is changed, the oil level

plug and breather must be relocated to proper

positions, as shown to the right.

Failure to change plug location will result in

blower failure and void the product warranty.

This manual suits for next models

12

Table of contents