DISCLAIMERS:

(SSPUMVYTH[PVUPSS\Z[YH[PVUZHUKZWLJPÄJH[PVUZPU[OPZTHU\HSHYLIHZLKVU[OLSH[LZ[PUMVYTH[PVUH]HPSHISLH[

[OL[PTLVMW\ISPZOPUN;OLPSS\Z[YH[PVUZ\ZLKPU[OPZTHU\HSHYLPU[LUKLKHZYLWYLZLU[H[P]LYLMLYLUJL]PL^ZVUS`

4VYLV]LYILJH\ZLVMV\YJVU[PU\V\ZWYVK\J[PTWYV]LTLU[WVSPJ`^LTH`TVKPM`PUMVYTH[PVUPSS\Z[YH[PVUZHUKVY

ZWLJPÄJH[PVUZ[VL_WSHPUHUKVYL_LTWSPM`HWYVK\J[ZLY]PJLVYTHPU[LUHUJLPTWYV]LTLU[>LYLZLY]L[OLYPNO[

[VTHRLHU`JOHUNLH[HU`[PTL^P[OV\[UV[PJL:VTLPTHNLZTH`]HY`KLWLUKPUN\WVU^OPJOTVKLSPZZOV^U

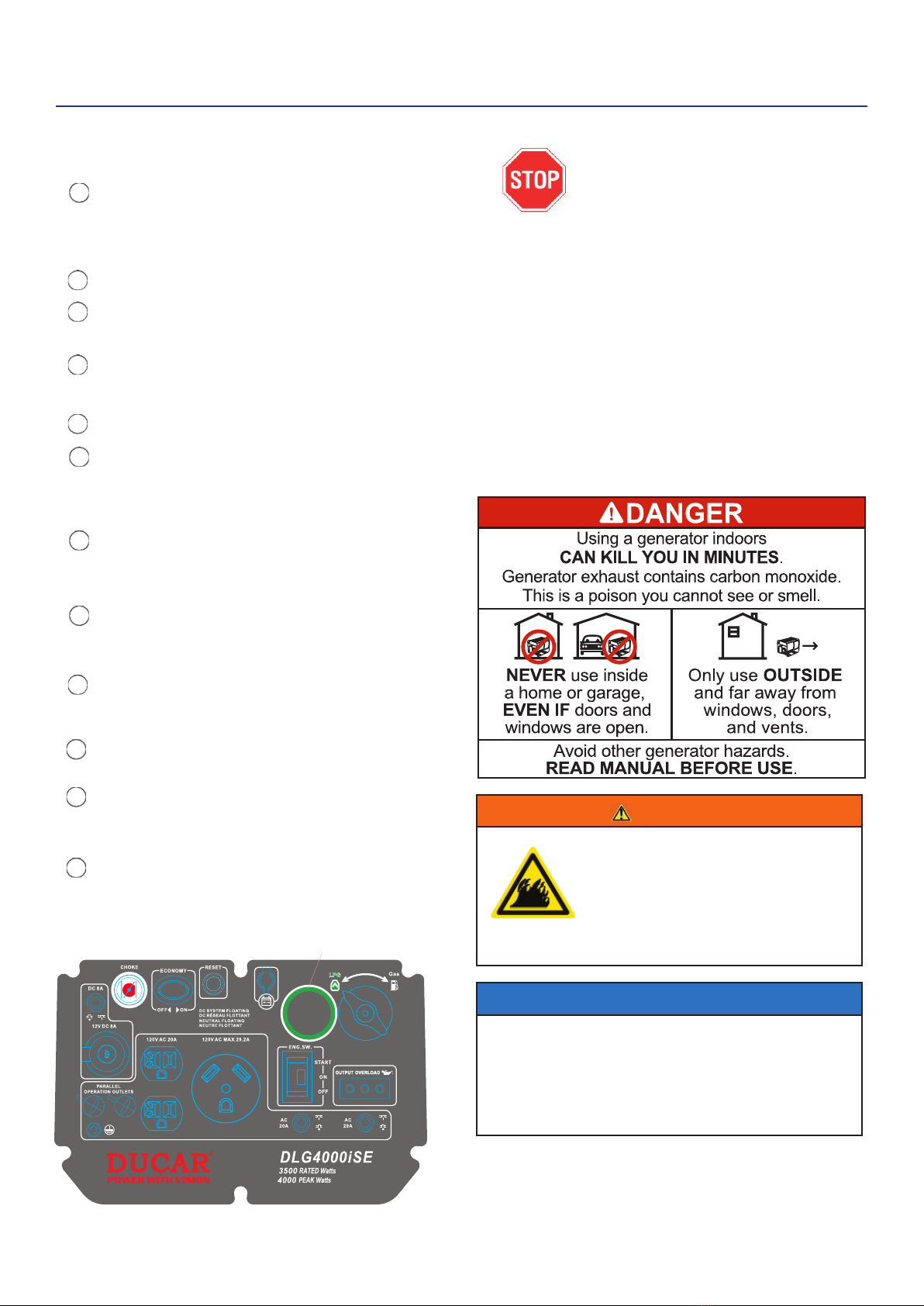

DANGER

;OPZTHU\HSJVU[HPUZPTWVY[HU[PUZ[Y\J[PVUZMVYVWLYH[PUN[OPZNLULYH[VY-VY`V\YZHML[`HUK[OLZHML[`VMV[OLYZILZ\YL

[VYLHK[OPZTHU\HS[OVYV\NOS`ILMVYLVWLYH[PUN[OLNLULYH[VY-HPS\YL[VWYVWLYS`MVSSV^HSSPUZ[Y\J[PVUZHUKWYLJH\[PVUZ

JHUJH\ZL`V\HUKV[OLYZ[VILZLYPV\ZS`O\Y[VYRPSSLK

"

#"

#"

$ %&

! '

(

)*!(

+

,-!+

) *+

. /

/

$*/

01/

-,2

*-12

*1!34

,5!!34

,5134

$!33

,.-$33

*36

! 3"

*3"

753"

1%3"

3&

3&

513'

,513'

513'

,513(

!3(

,!3(

#!)3+

-3+

, 3/

,89.3/

,*32

) 32

64

63

WARRANTY ........................................................................................................................................................................................................................................................................ 22