Contents

Operator and Equipment Safety ............................................................................................................................................5

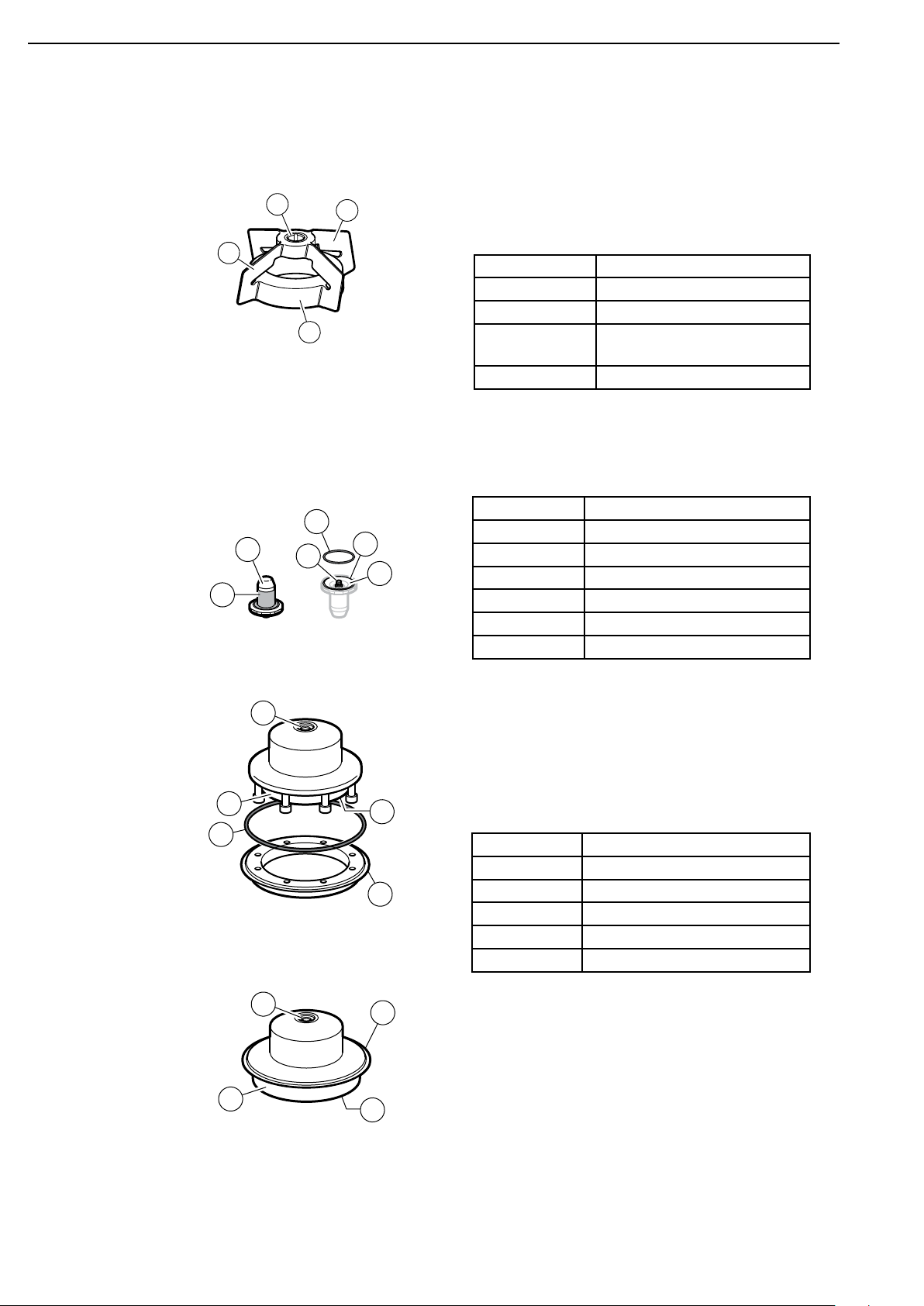

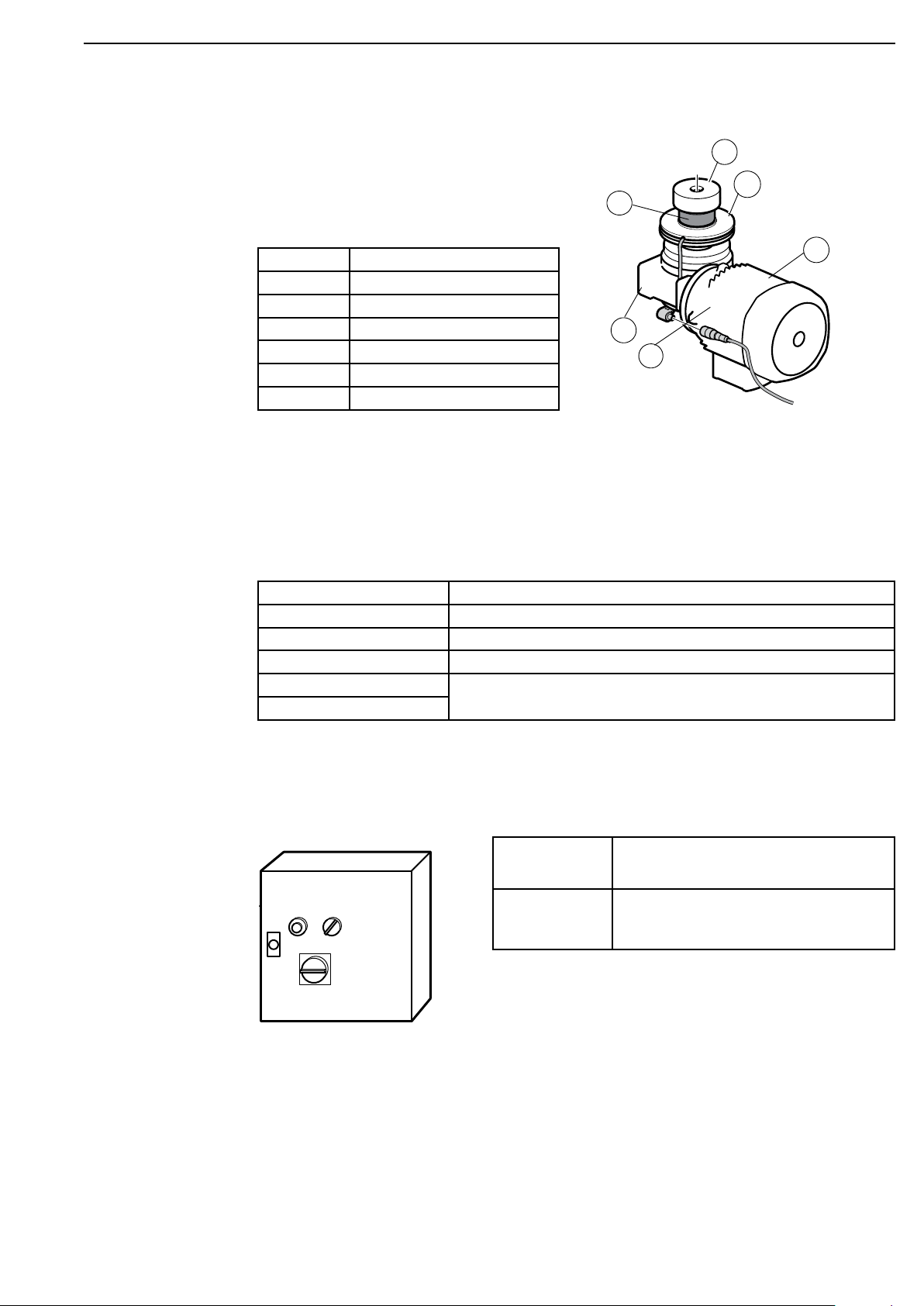

NovAseptic®GMP Mixer Components ..................................................................................................................................6

Required Tools..................................................................................................................................................................7

Additional Equipment....................................................................................................................................................7

Optional Equipment........................................................................................................................................................8

Installation and Operating Parameters................................................................................................................................9

Installation................................................................................................................................................................................ 10

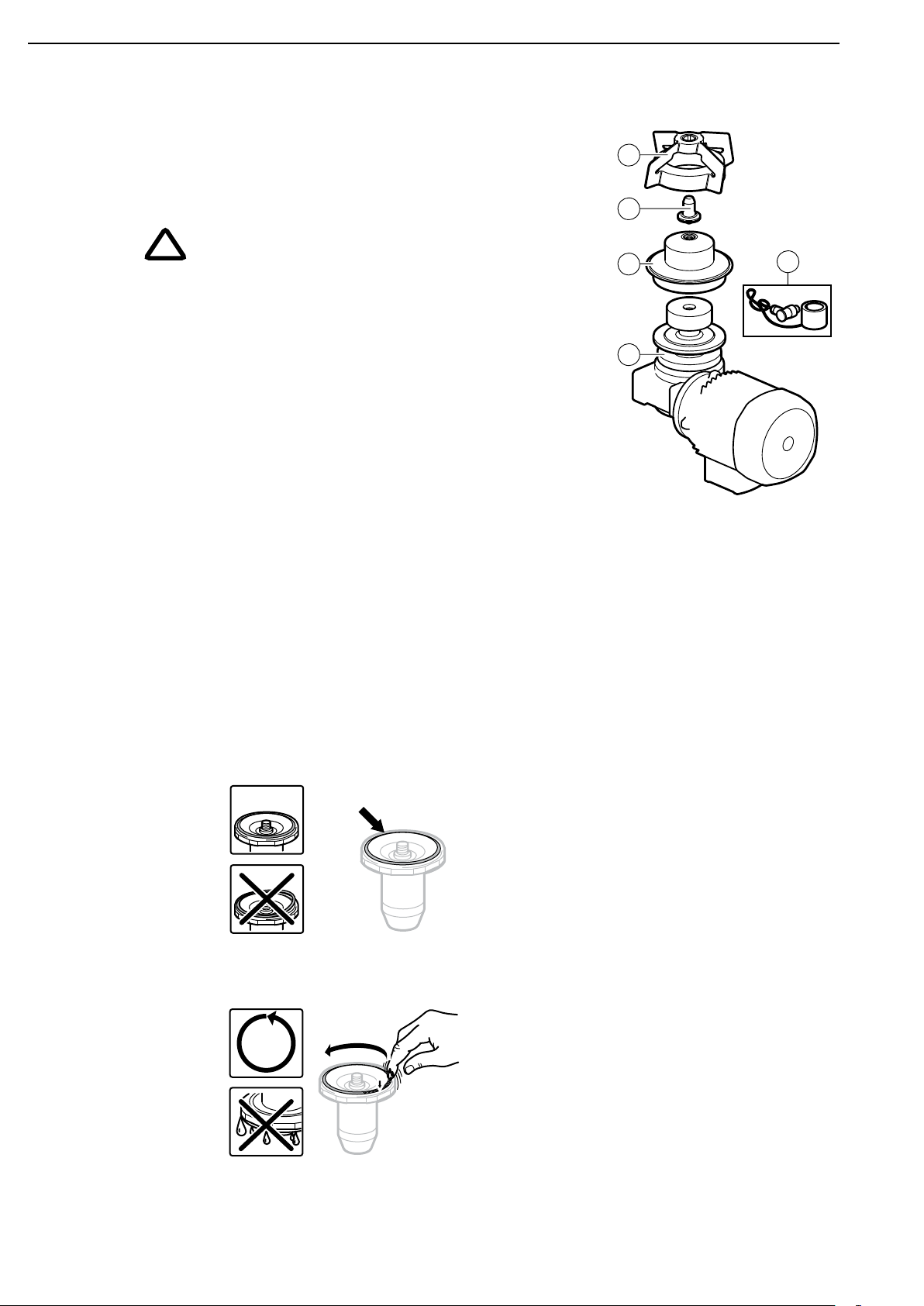

Male Bearing Installation.......................................................................................................................................... 10

Mixing Head Installation ........................................................................................................................................... 11

Drive Unit Installation ................................................................................................................................................ 12

Electrical Installation.................................................................................................................................................. 14

Operation................................................................................................................................................................................... 20

Starting the Mixer ....................................................................................................................................................... 20

Disassembly ................................................................................................................................................................... 21

Storage............................................................................................................................................................................ 21

Recycle and Disposal................................................................................................................................................... 21

Cleaning and Sterilizing Procedures.................................................................................................................................. 22

Cleaning in Place (CIP) ............................................................................................................................................... 22

Sterilizing in Place (SIP) ............................................................................................................................................. 22

Installation Checklist ............................................................................................................................................................. 24

Commissioning ........................................................................................................................................................................ 26

Valid Regulations ......................................................................................................................................................... 26

Installation Qualification Checklist ................................................................................................................................... 27

Installation Qualification ........................................................................................................................................ 27

Check Points.................................................................................................................................................................. 27

Maintenance Checklist.......................................................................................................................................................... 29

Spare Parts................................................................................................................................................................................ 30

Troubleshooting ....................................................................................................................................................................... 31

Standard Product Warranty ................................................................................................................................................. 33

Technical Assistance............................................................................................................................................................... 34

NovAseptic®GMP Mixer Installation and User Guide 3