M2 Antenna Systems 6.9-4CDD-125 User manual

Other M2 Antenna Systems Antenna manuals

M2 Antenna Systems

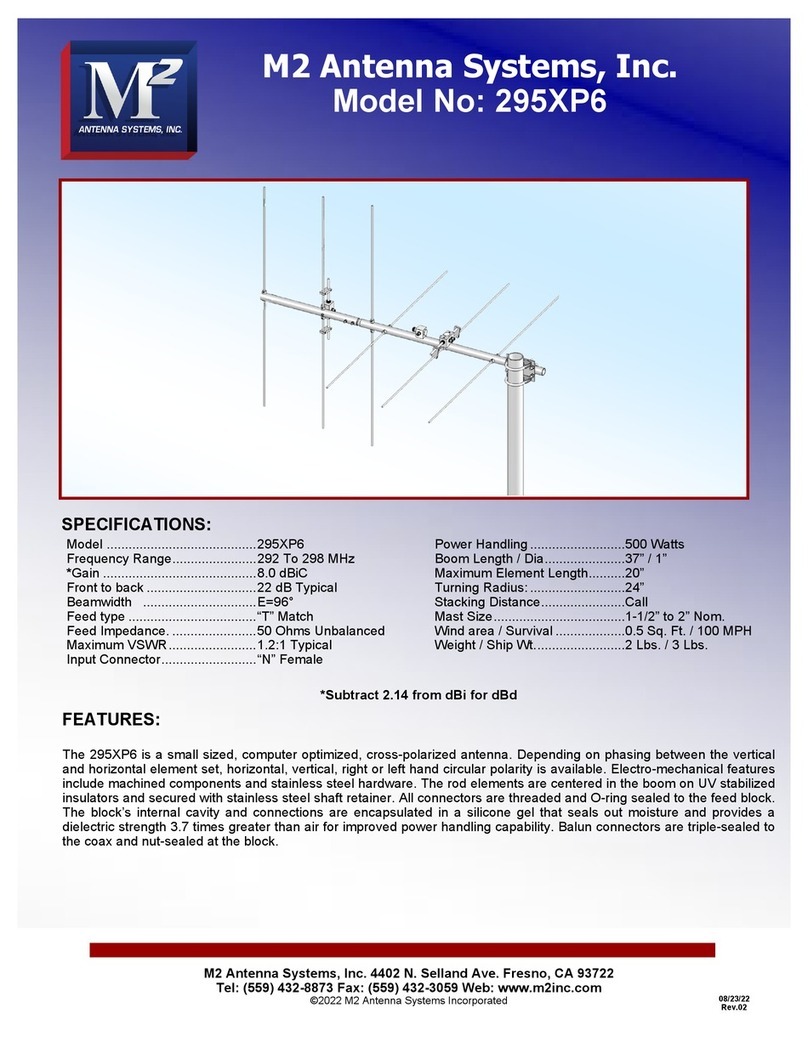

M2 Antenna Systems 295XP6 User manual

M2 Antenna Systems

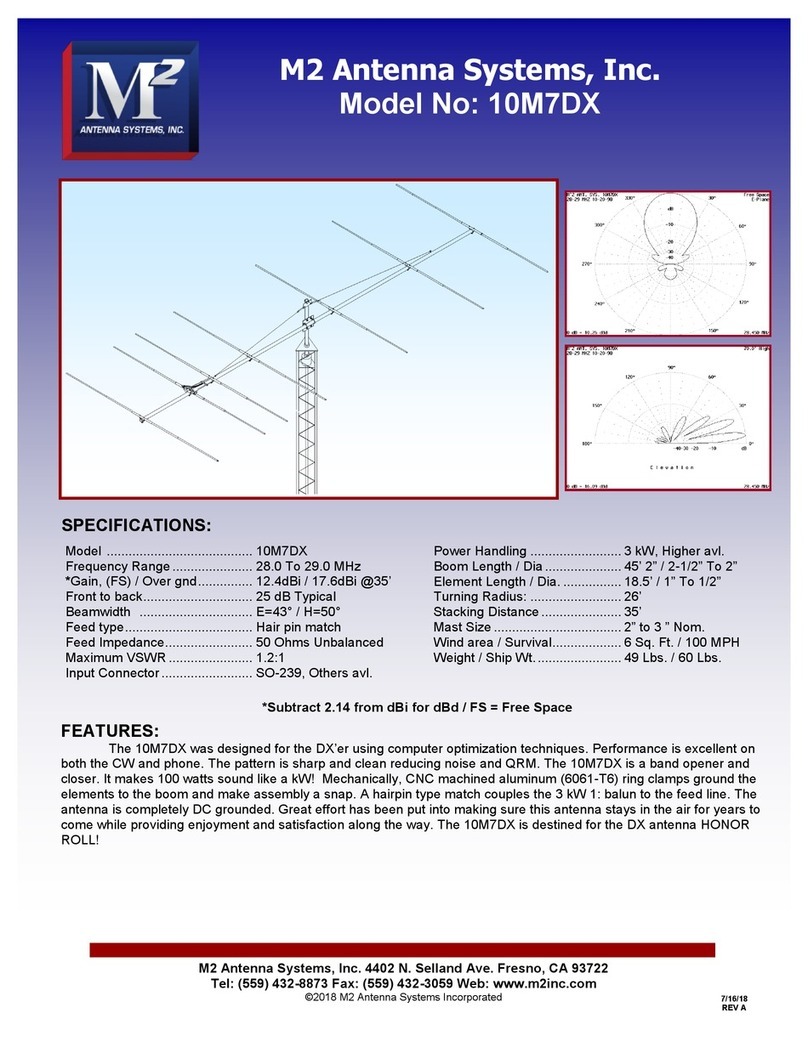

M2 Antenna Systems 10M7DX User manual

M2 Antenna Systems

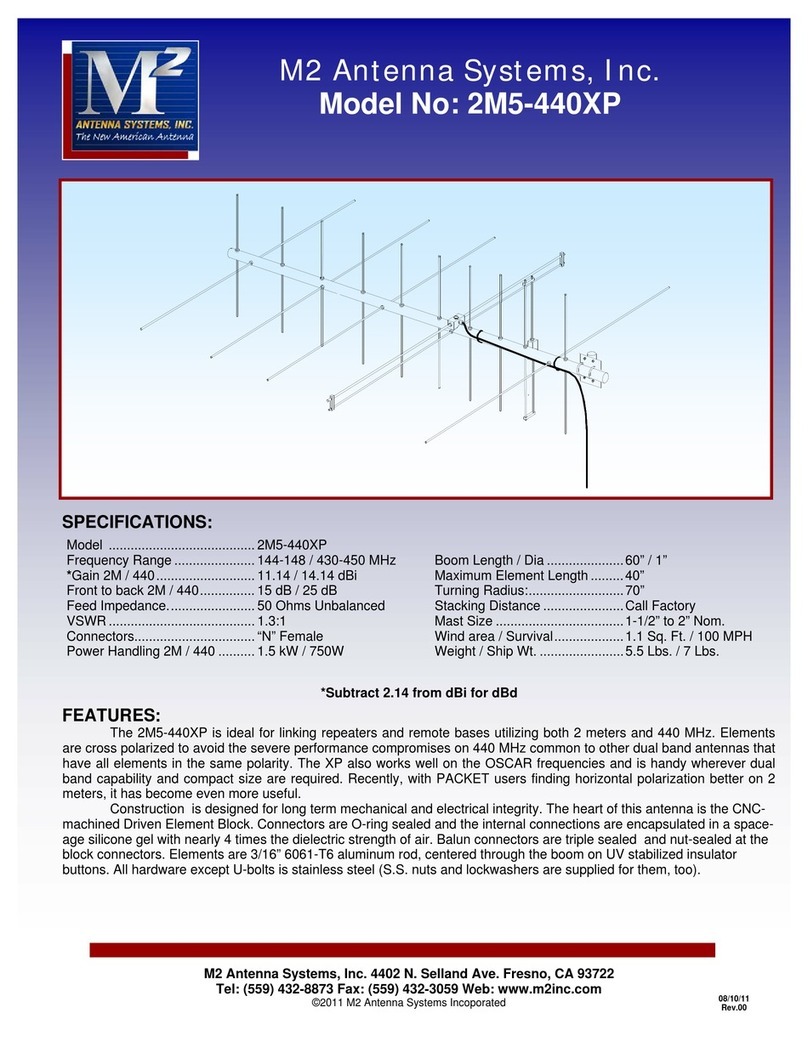

M2 Antenna Systems 2M5-440XP User manual

M2 Antenna Systems

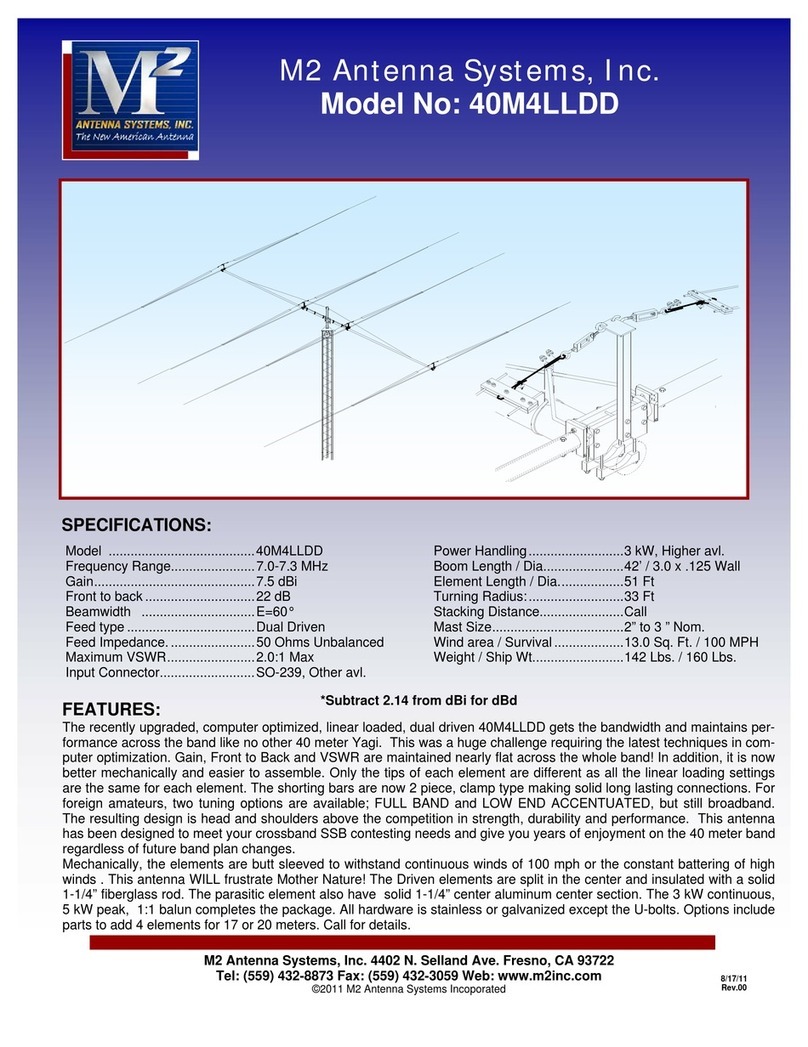

M2 Antenna Systems 40M4LLDD User manual

M2 Antenna Systems

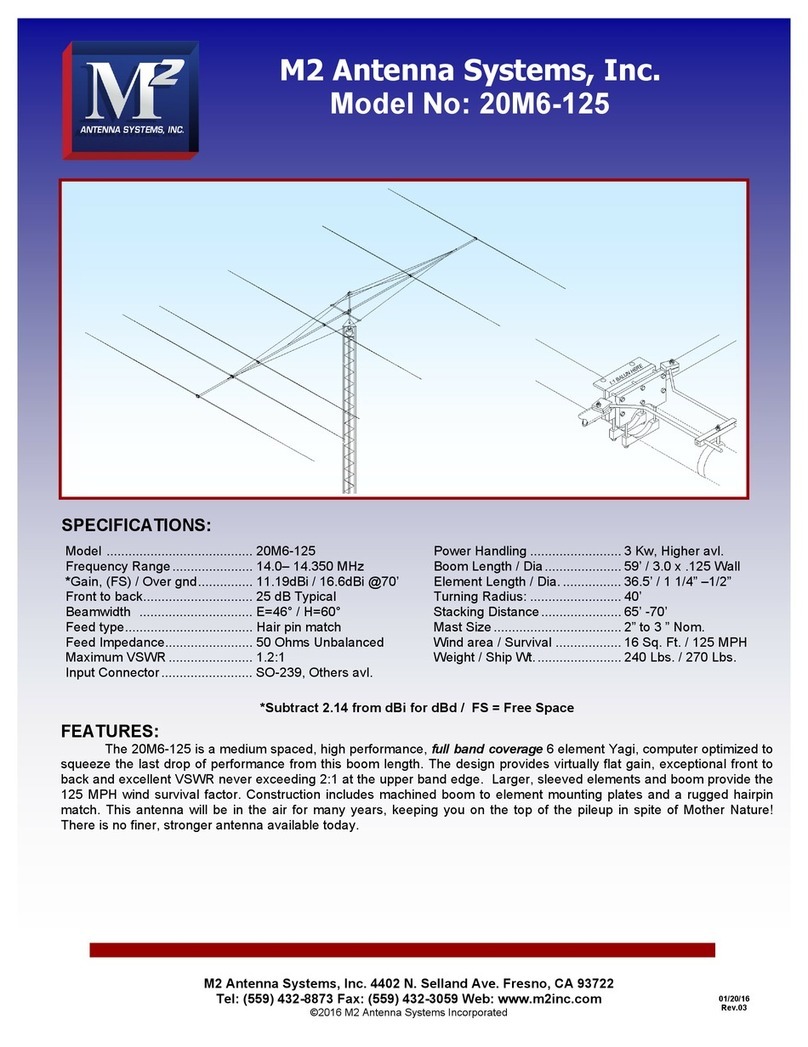

M2 Antenna Systems 20M6-125 User manual

M2 Antenna Systems

M2 Antenna Systems 20M5-125 User manual

M2 Antenna Systems

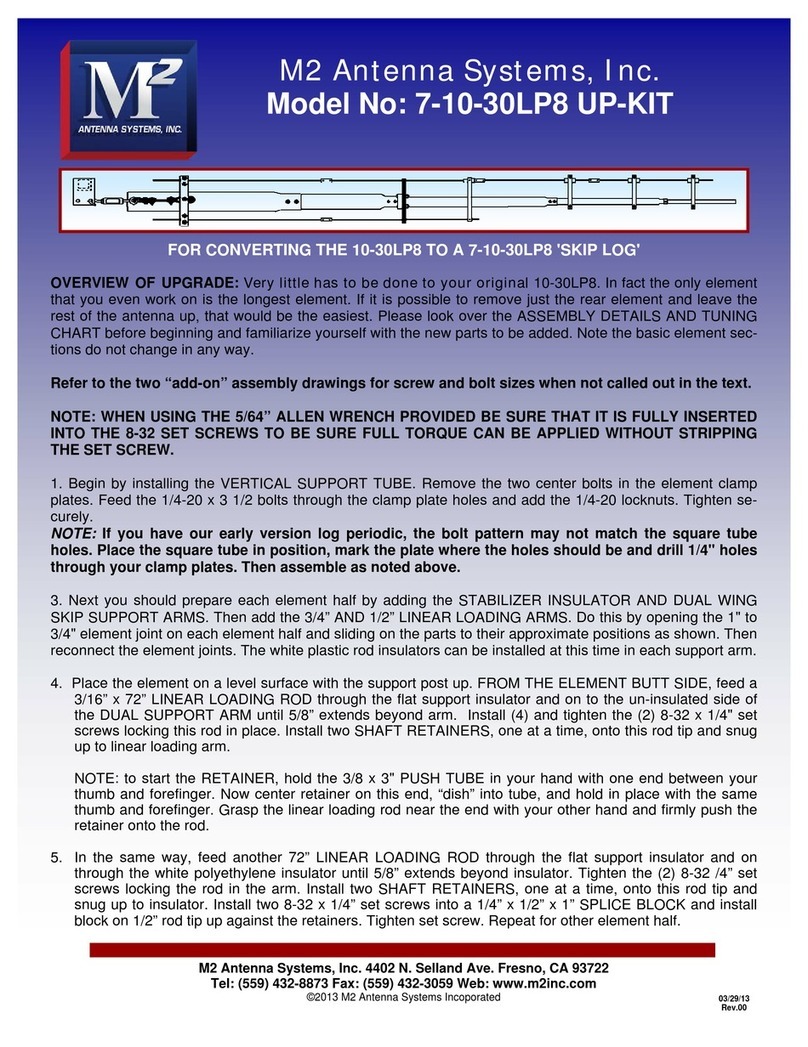

M2 Antenna Systems 7-10-30LP8 UP-KIT User manual

M2 Antenna Systems

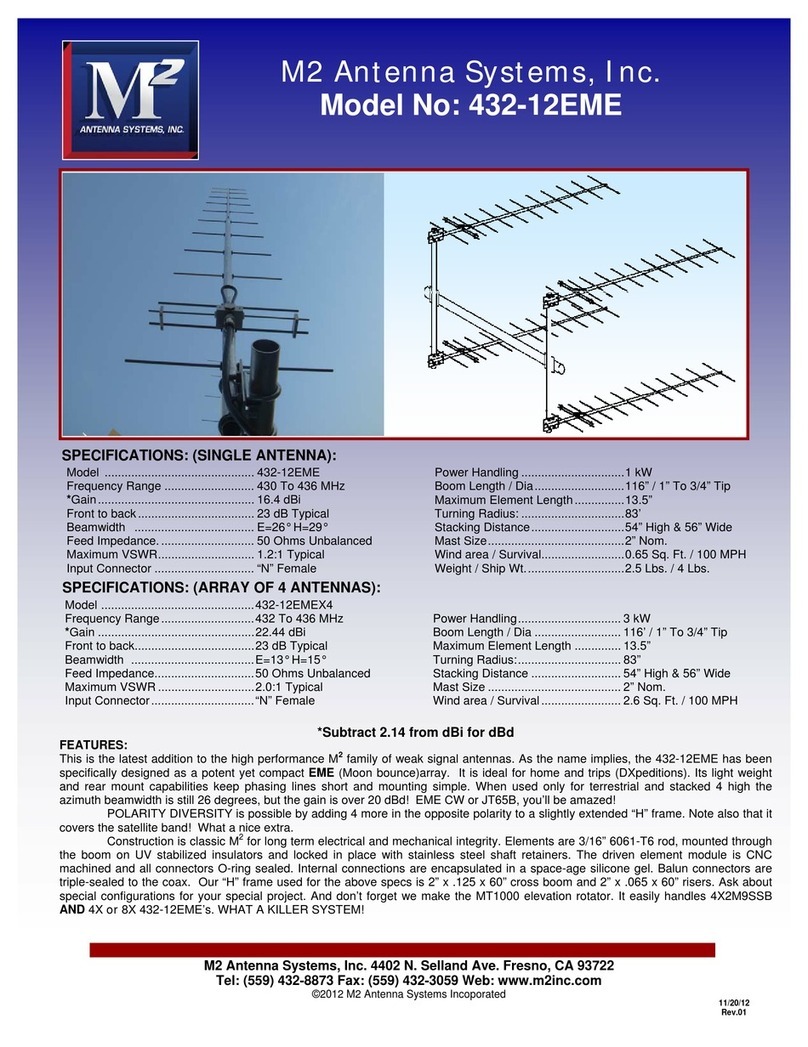

M2 Antenna Systems 432-12EME User manual

M2 Antenna Systems

M2 Antenna Systems 75-5AS User manual

M2 Antenna Systems

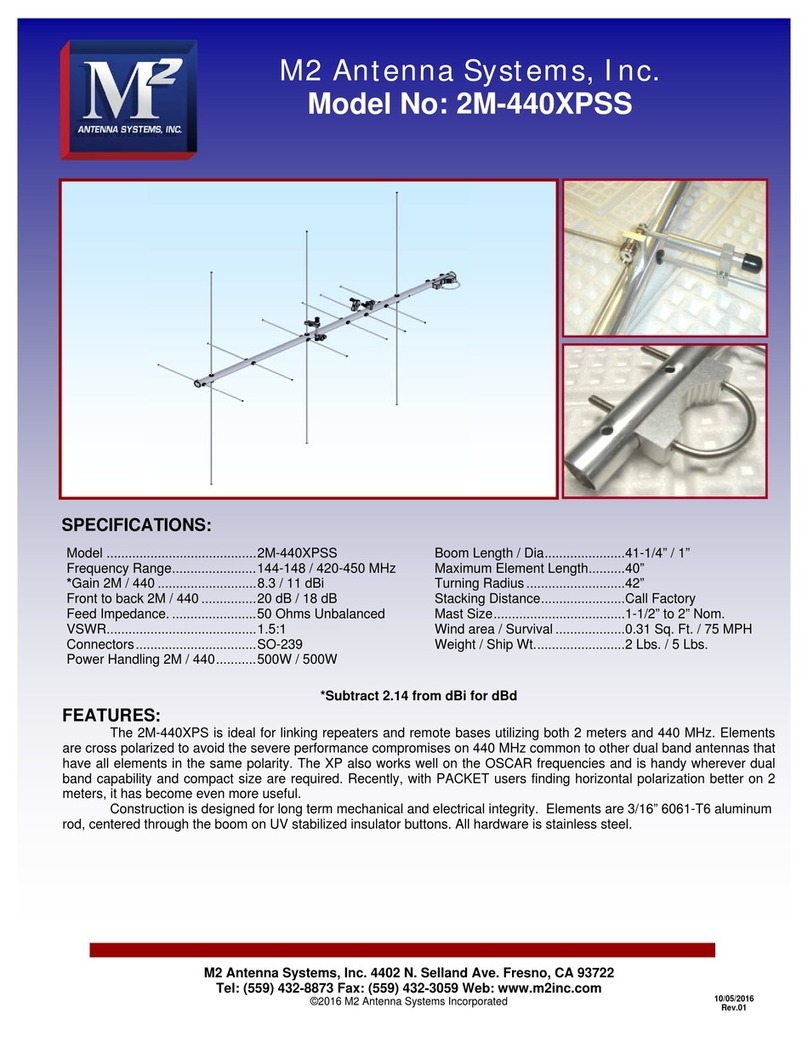

M2 Antenna Systems 2M-440XPSS User manual

M2 Antenna Systems

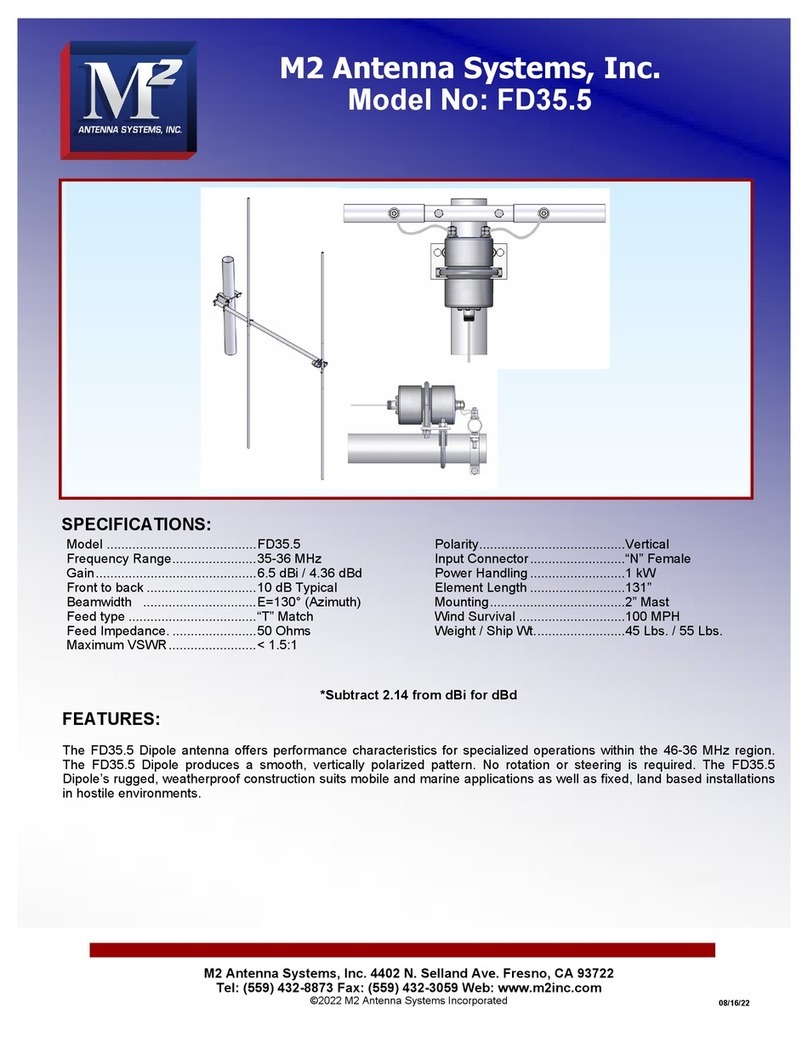

M2 Antenna Systems FD35.5 User manual

M2 Antenna Systems

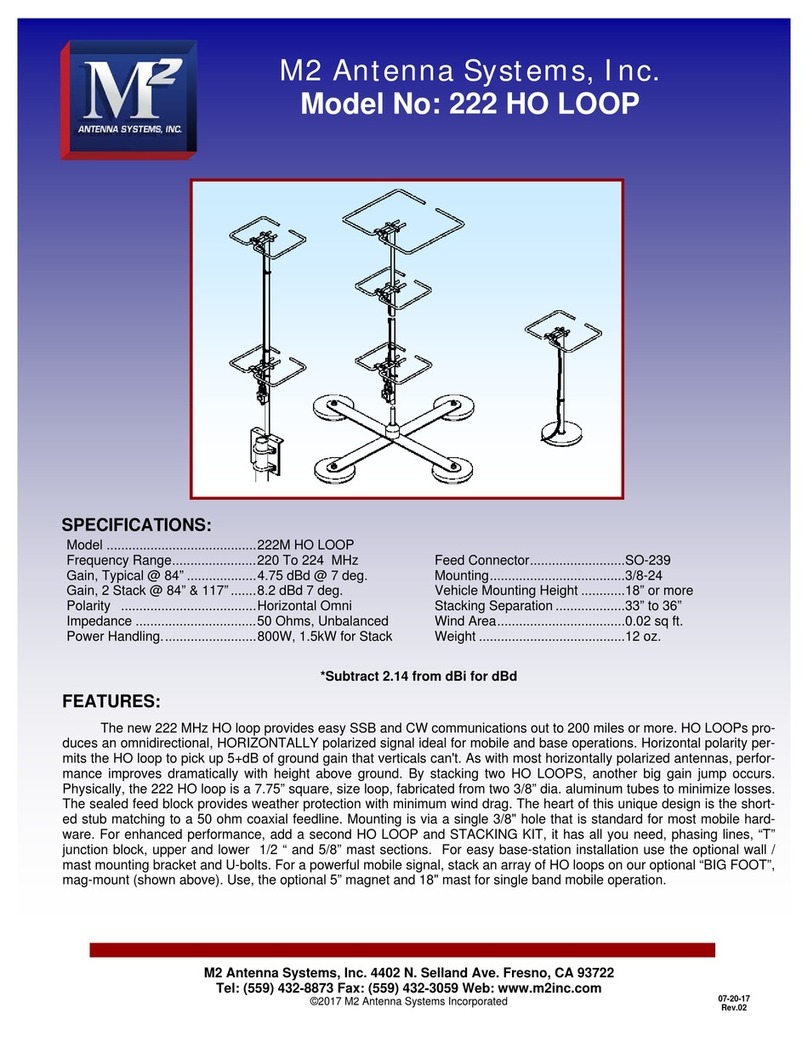

M2 Antenna Systems 222 HO LOOP User manual

M2 Antenna Systems

M2 Antenna Systems 2M5WL User manual

M2 Antenna Systems

M2 Antenna Systems 2MCP8A User manual

M2 Antenna Systems

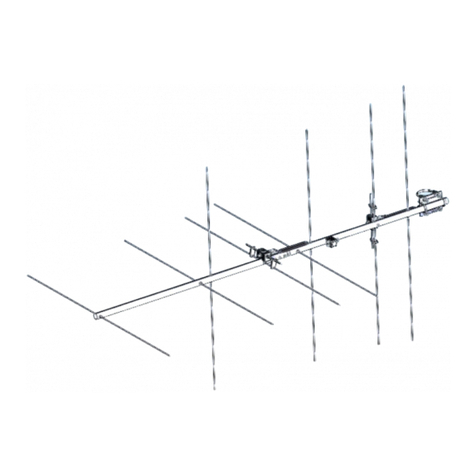

M2 Antenna Systems 2M4 User manual

M2 Antenna Systems

M2 Antenna Systems 450-800-12 User manual

M2 Antenna Systems

M2 Antenna Systems FG2227-21X4CP User manual

M2 Antenna Systems

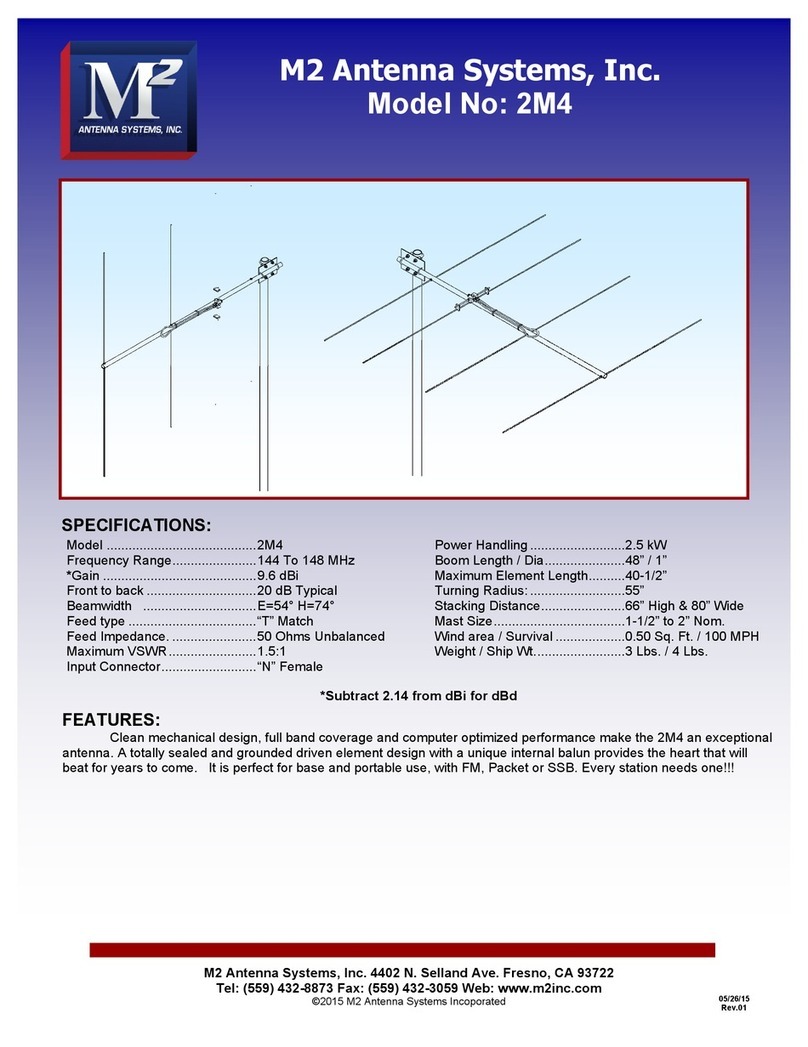

M2 Antenna Systems 400-800-8 User manual

M2 Antenna Systems

M2 Antenna Systems 2M8WL User manual

M2 Antenna Systems

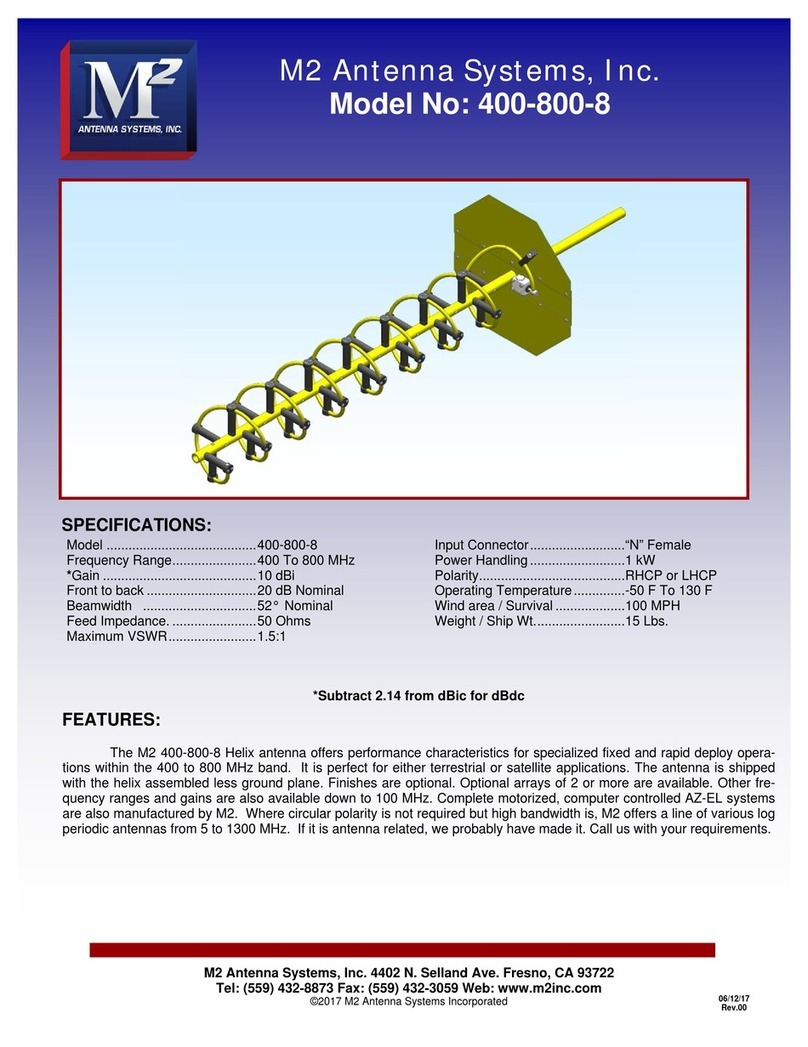

M2 Antenna Systems 40M2C User manual

Popular Antenna manuals by other brands

Alfa Network

Alfa Network APA-L01 Specifications

Naval

Naval PR-422CA Operation manual

Feig Electronic

Feig Electronic ID ISC.ANTH200/200 Series manual

TERK Technologies

TERK Technologies TV44 owner's manual

Directive Systems & Engineering

Directive Systems & Engineering DSE2324LYRMK quick start guide

HP

HP J8999A instructions

CommScope

CommScope CMAX-OMFX-43M-I53 Installation instruction

Ramsey Electronics

Ramsey Electronics DAP25 Kit assembly and instruction manual

COBHAM

COBHAM SAILOR 800 VSAT Replacement procedure

Trango Systems

Trango Systems AD900-9 Specification sheet

Steren

Steren ANT-100 user manual

IWCS

IWCS iriBelt II Quick start user guide