M2 Antenna Systems 40M2C User manual

Other M2 Antenna Systems Antenna manuals

M2 Antenna Systems

M2 Antenna Systems 222-10EZ User manual

M2 Antenna Systems

M2 Antenna Systems 420-450-11HP User manual

M2 Antenna Systems

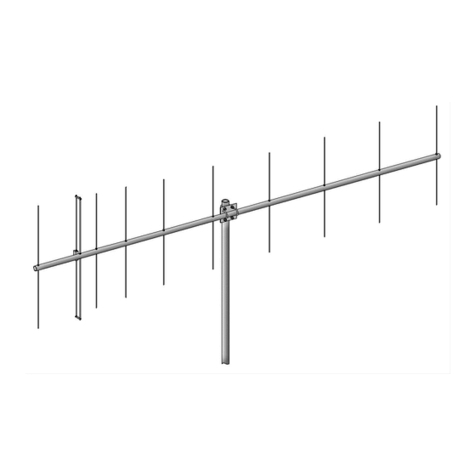

M2 Antenna Systems 303CP26 User manual

M2 Antenna Systems

M2 Antenna Systems 406-6SX User manual

M2 Antenna Systems

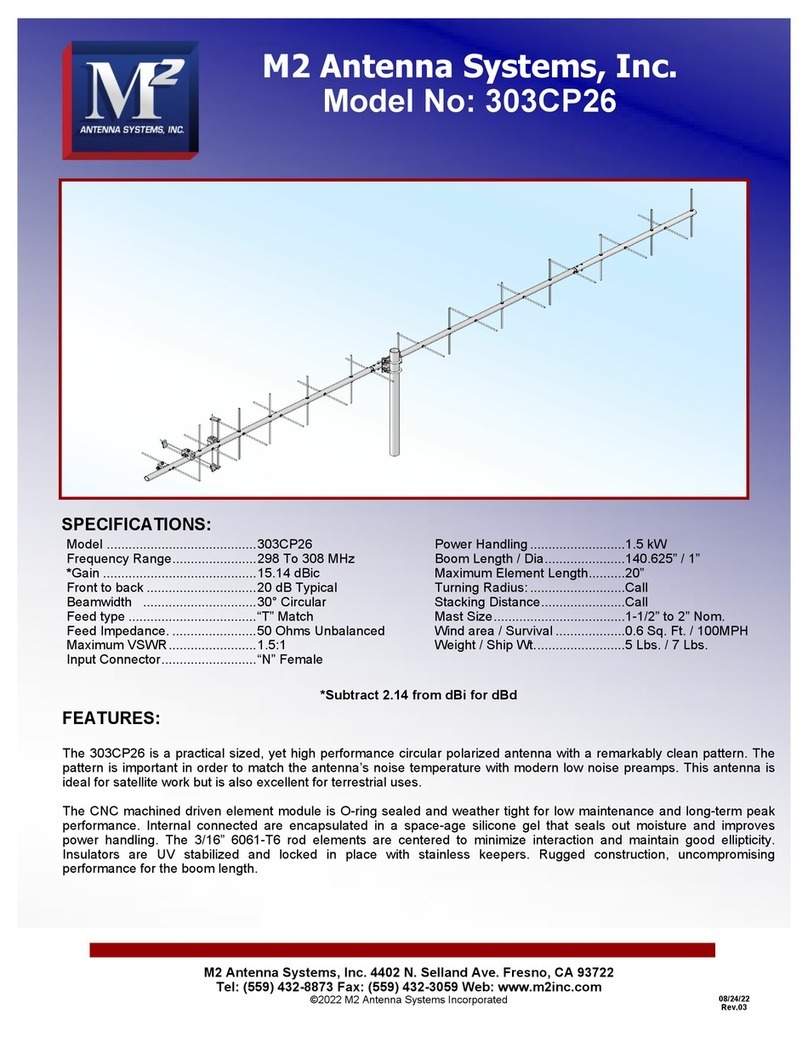

M2 Antenna Systems 10M7DX User manual

M2 Antenna Systems

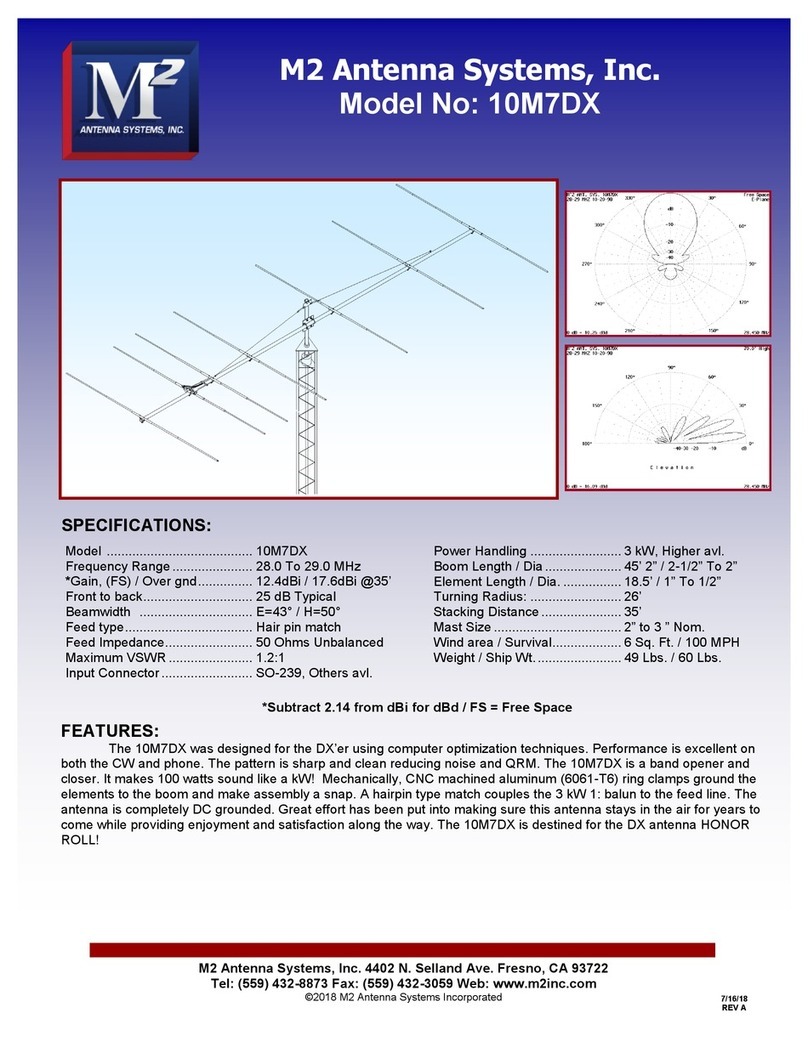

M2 Antenna Systems 6.9-4CDD-125 User manual

M2 Antenna Systems

M2 Antenna Systems 12M4DX User manual

M2 Antenna Systems

M2 Antenna Systems EB-432/RK70CM User manual

M2 Antenna Systems

M2 Antenna Systems KT34M2 User manual

M2 Antenna Systems

M2 Antenna Systems 40M1L User manual

M2 Antenna Systems

M2 Antenna Systems 75-5AS User manual

M2 Antenna Systems

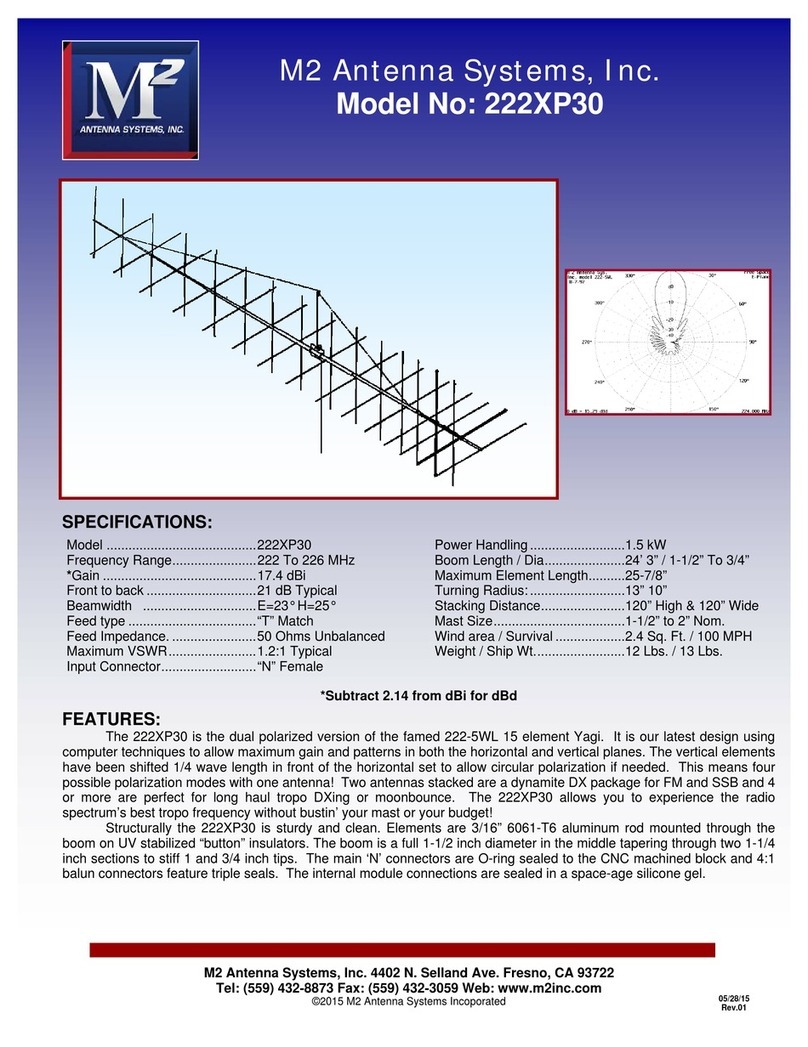

M2 Antenna Systems 222XP30 User manual

M2 Antenna Systems

M2 Antenna Systems 440-460-11HD User manual

M2 Antenna Systems

M2 Antenna Systems 2MCP22 User manual

M2 Antenna Systems

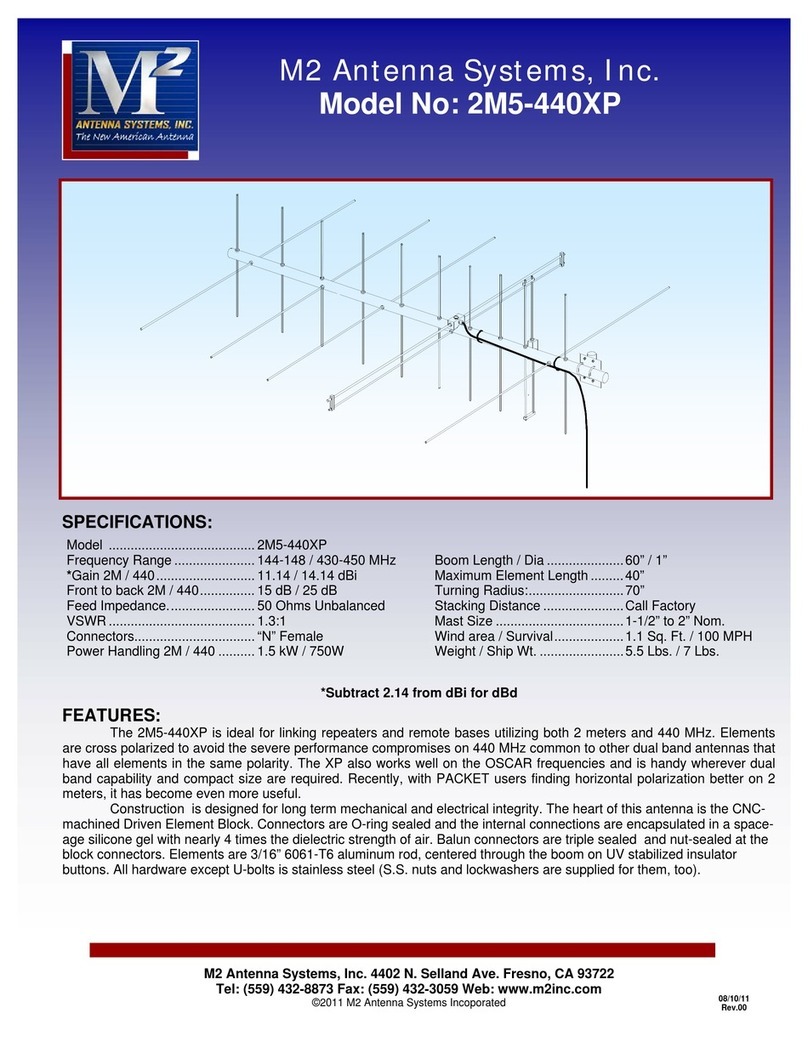

M2 Antenna Systems 2M5-440XP User manual

M2 Antenna Systems

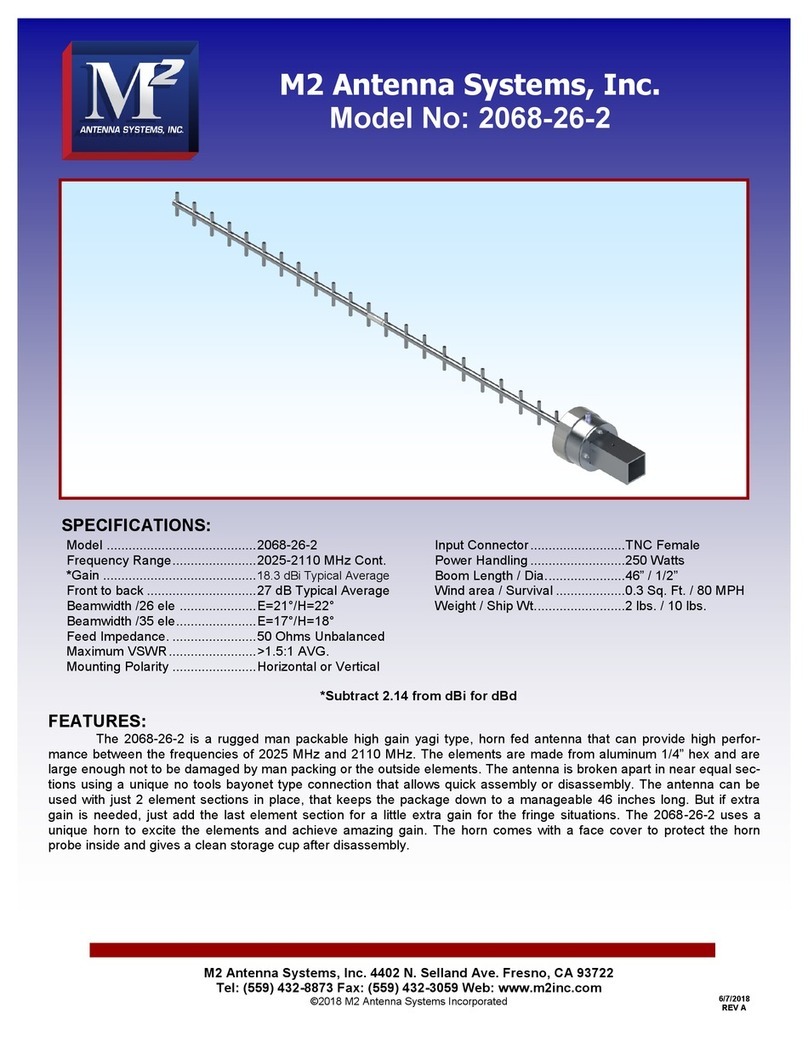

M2 Antenna Systems 2068-26-2 User manual

M2 Antenna Systems

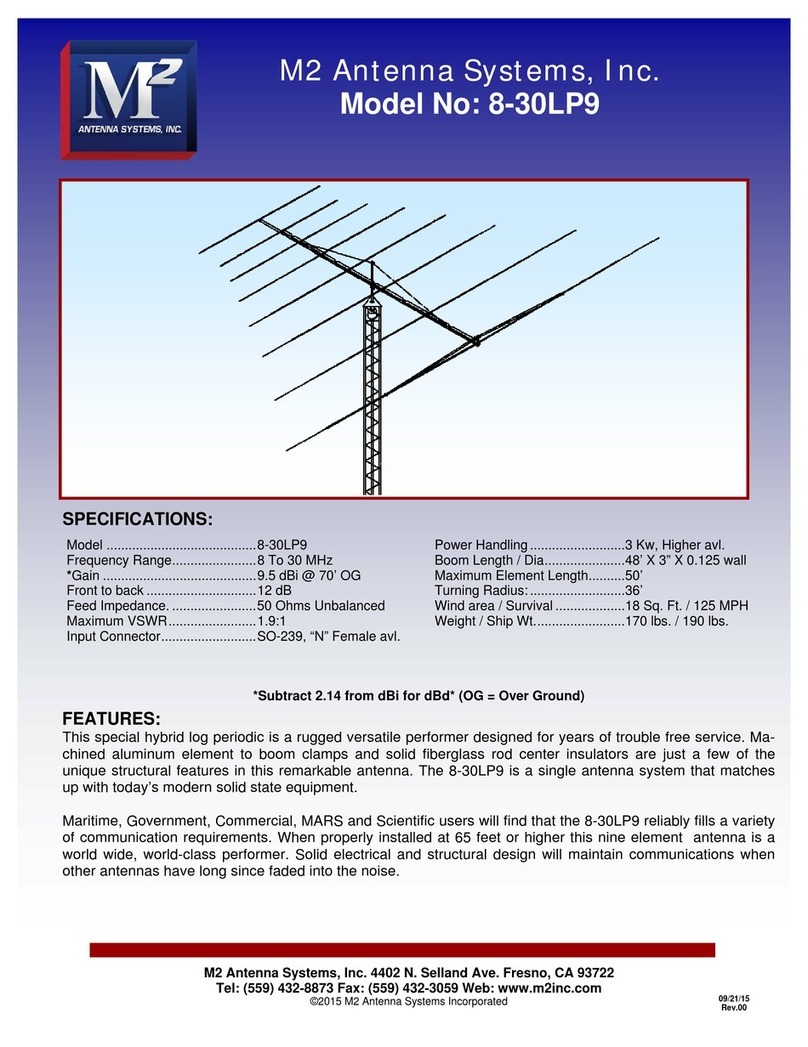

M2 Antenna Systems 8-30LP9 User manual

M2 Antenna Systems

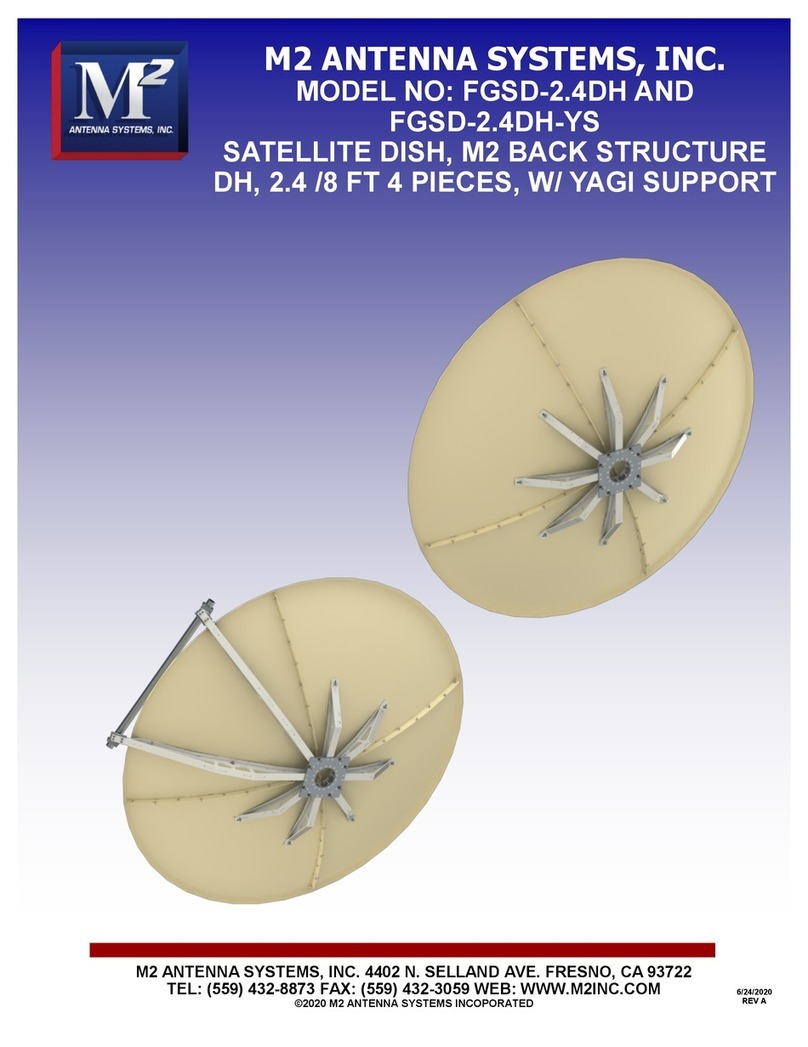

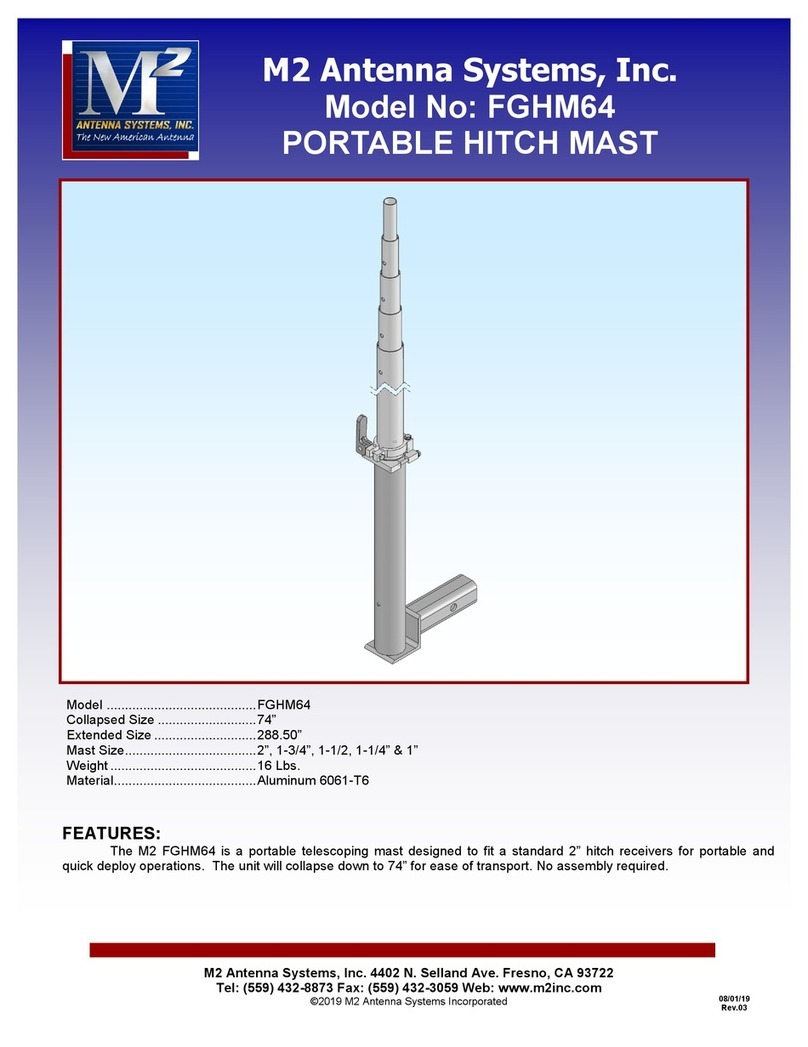

M2 Antenna Systems FGHM64 User manual

M2 Antenna Systems

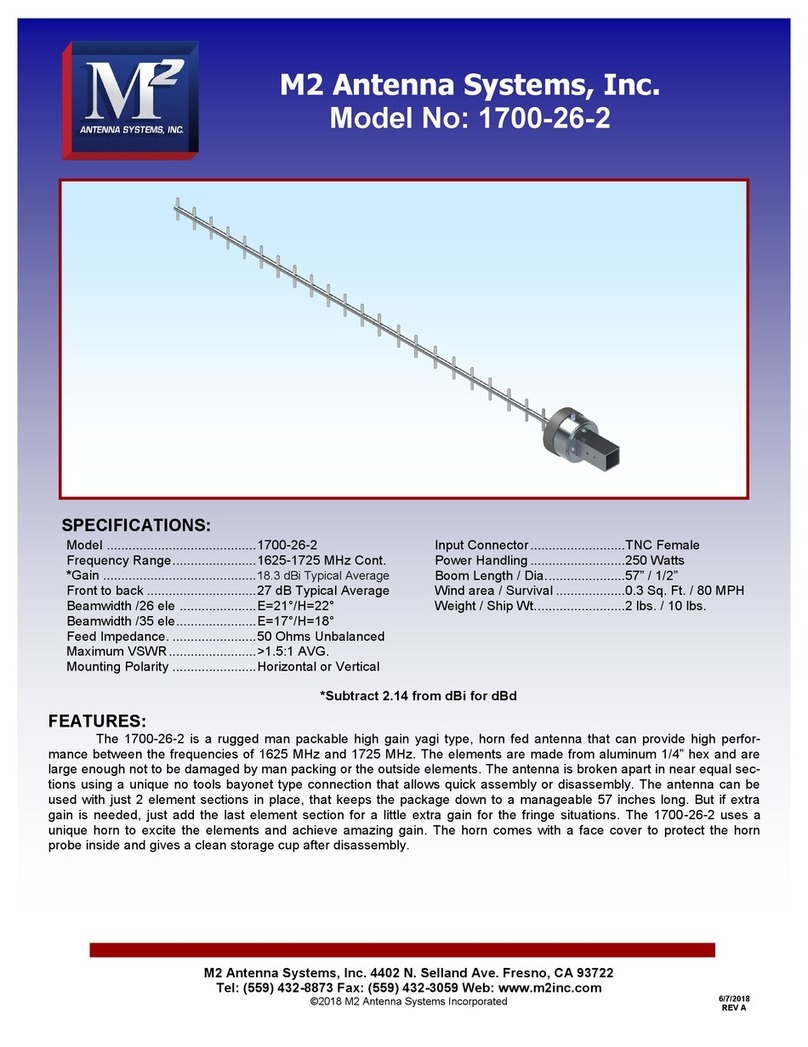

M2 Antenna Systems 1700-26-2 User manual

M2 Antenna Systems

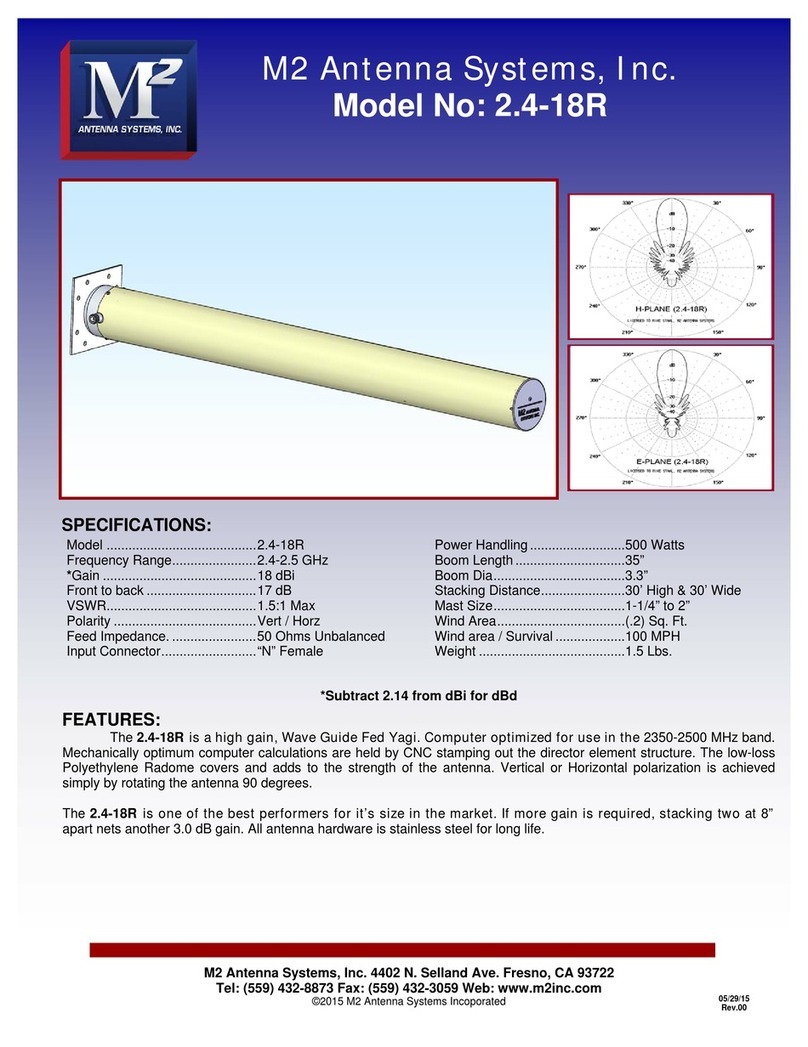

M2 Antenna Systems 2.4-18R User manual

Popular Antenna manuals by other brands

Alfa Network

Alfa Network APA-L01 Specifications

Naval

Naval PR-422CA Operation manual

Feig Electronic

Feig Electronic ID ISC.ANTH200/200 Series manual

TERK Technologies

TERK Technologies TV44 owner's manual

Directive Systems & Engineering

Directive Systems & Engineering DSE2324LYRMK quick start guide

HP

HP J8999A instructions

CommScope

CommScope CMAX-OMFX-43M-I53 Installation instruction

Ramsey Electronics

Ramsey Electronics DAP25 Kit assembly and instruction manual

COBHAM

COBHAM SAILOR 800 VSAT Replacement procedure

Trango Systems

Trango Systems AD900-9 Specification sheet

Steren

Steren ANT-100 user manual

IWCS

IWCS iriBelt II Quick start user guide