M2 Antenna Systems 80M1L User manual

Other M2 Antenna Systems Antenna manuals

M2 Antenna Systems

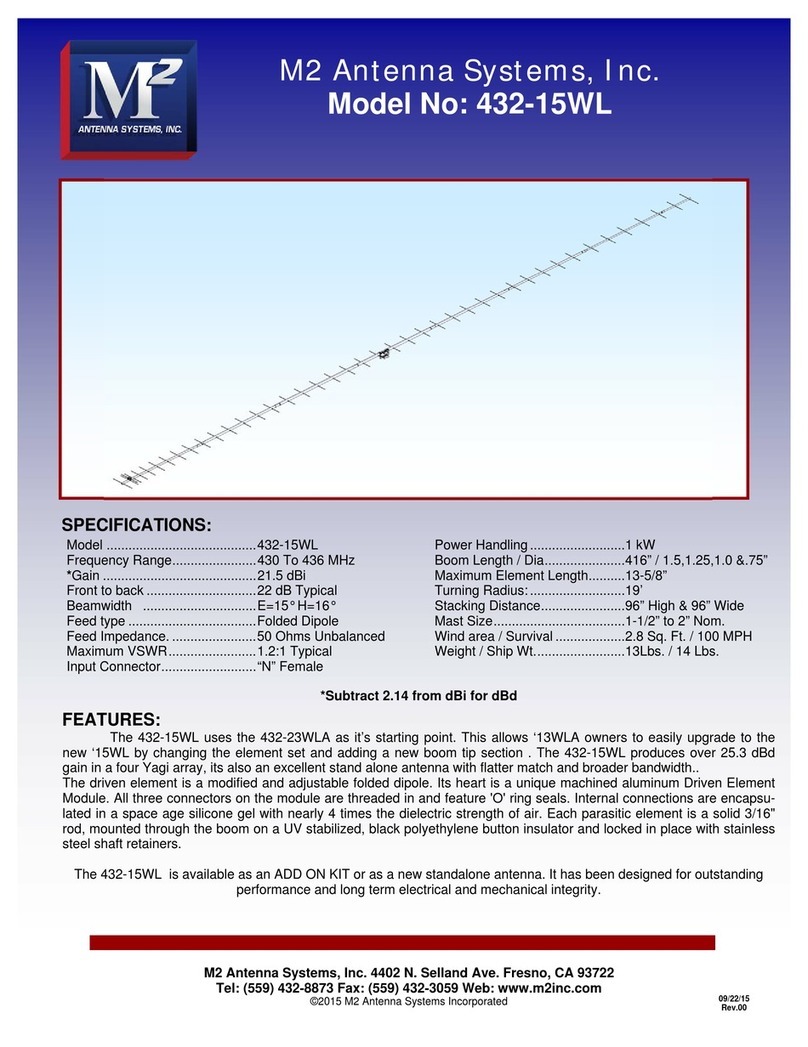

M2 Antenna Systems 432-15WL Quick start guide

M2 Antenna Systems

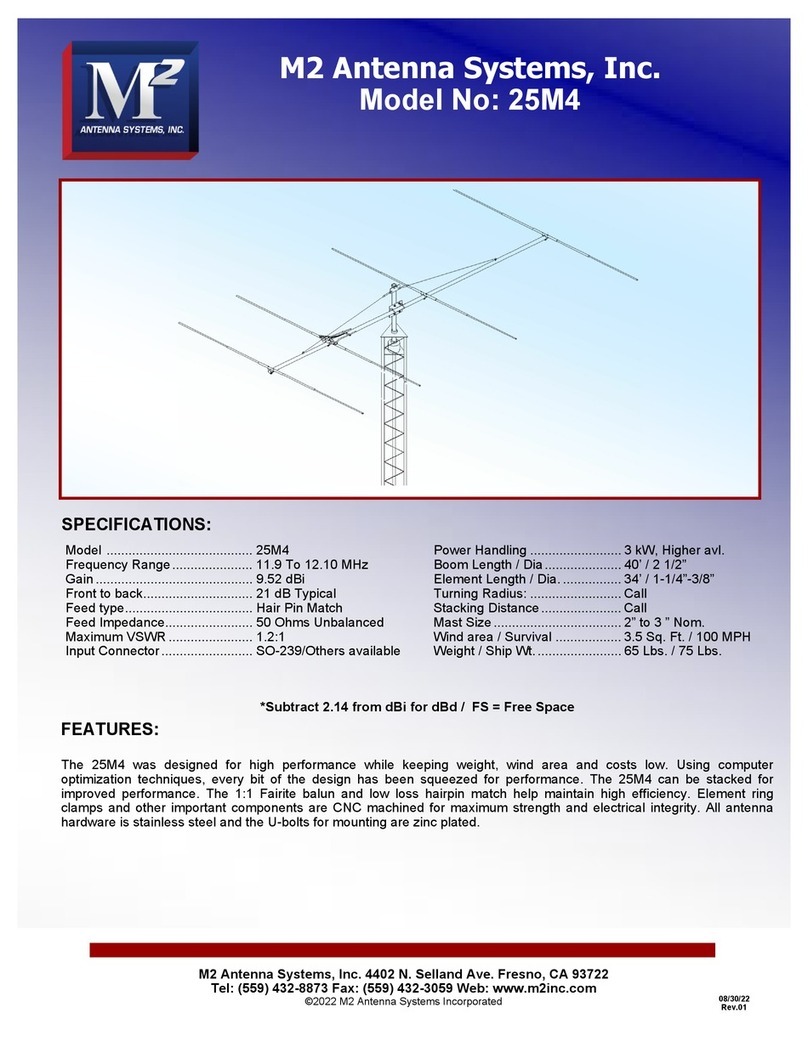

M2 Antenna Systems 25M4 User manual

M2 Antenna Systems

M2 Antenna Systems 432-6WL User manual

M2 Antenna Systems

M2 Antenna Systems 137CP14HD User manual

M2 Antenna Systems

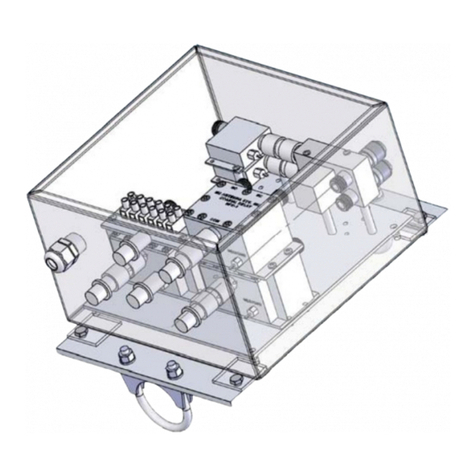

M2 Antenna Systems Relay/Preamp Housing with MAP65 User manual

M2 Antenna Systems

M2 Antenna Systems 436CP42UG User manual

M2 Antenna Systems

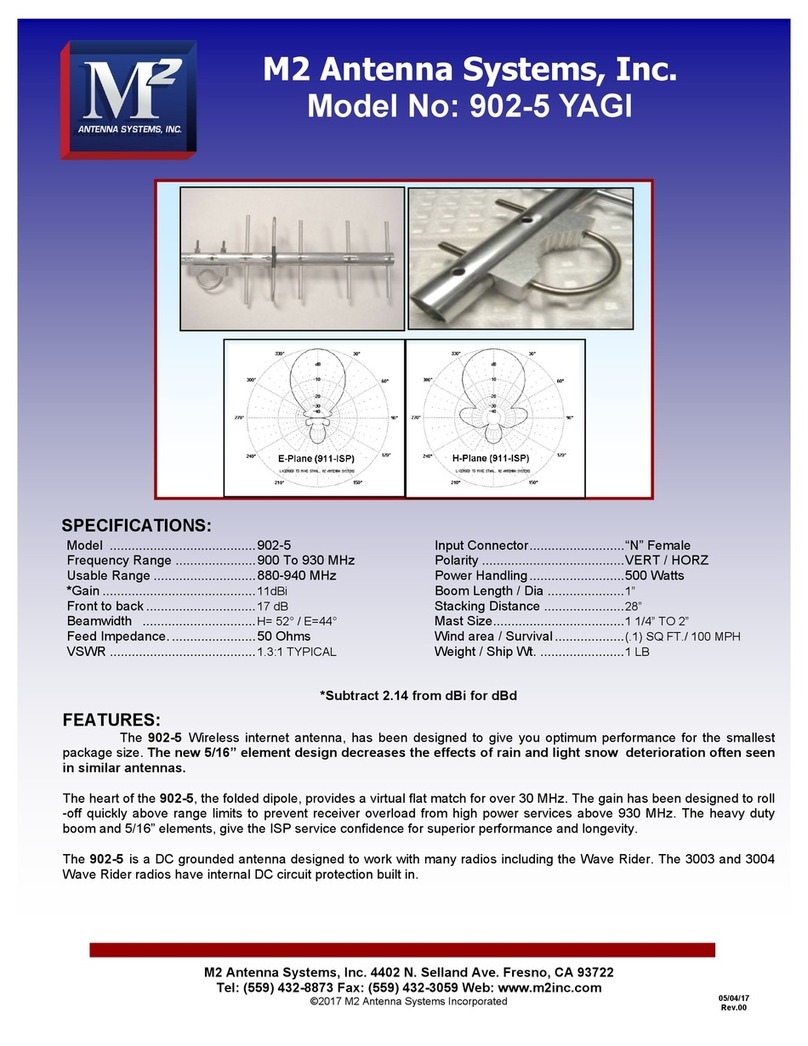

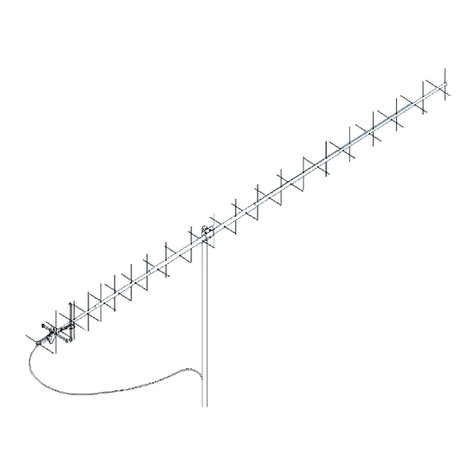

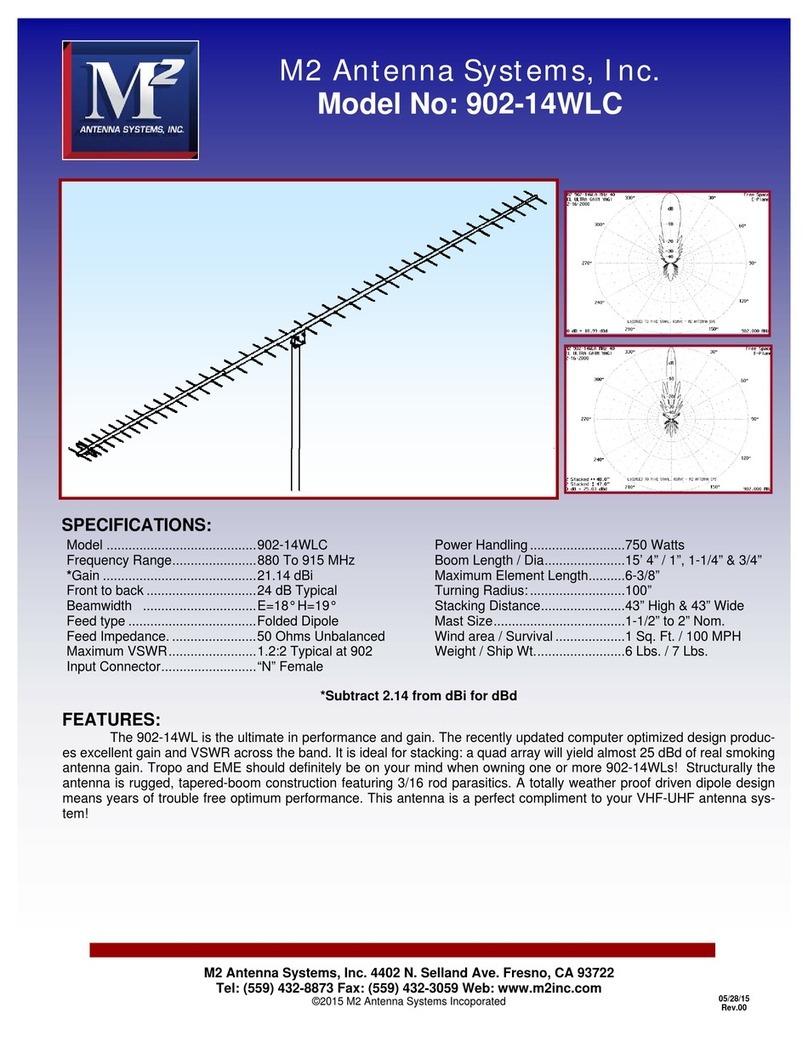

M2 Antenna Systems 902-14WLC User manual

M2 Antenna Systems

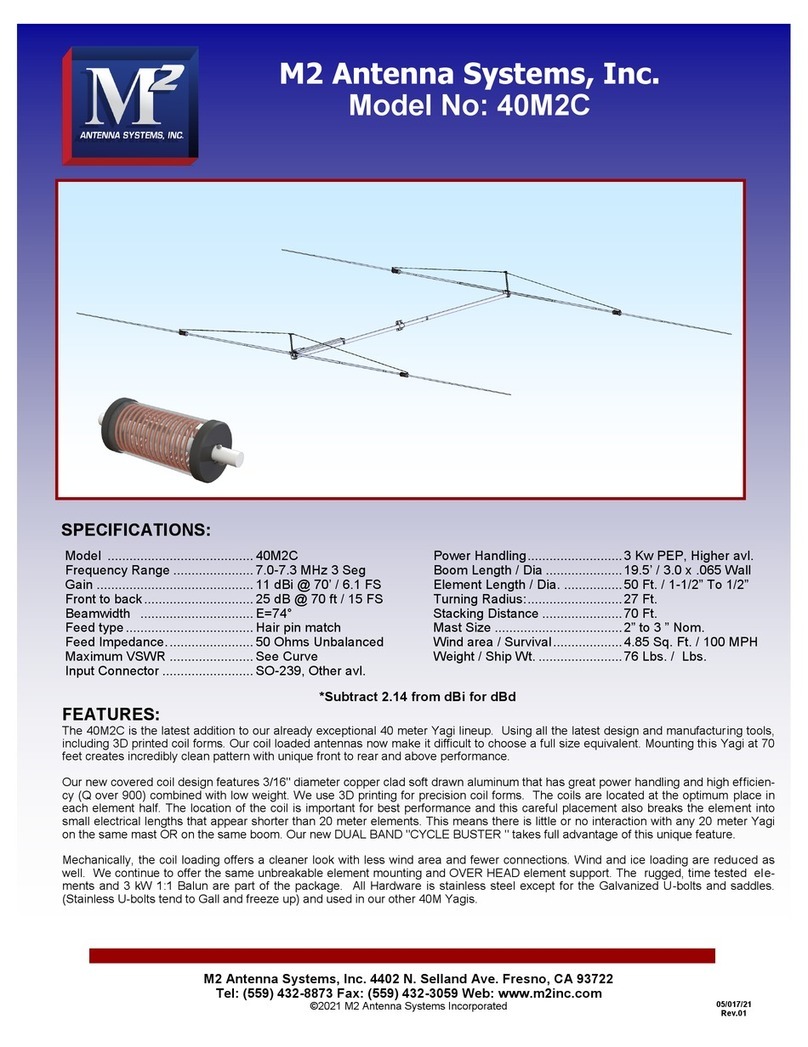

M2 Antenna Systems 40M2C User manual

M2 Antenna Systems

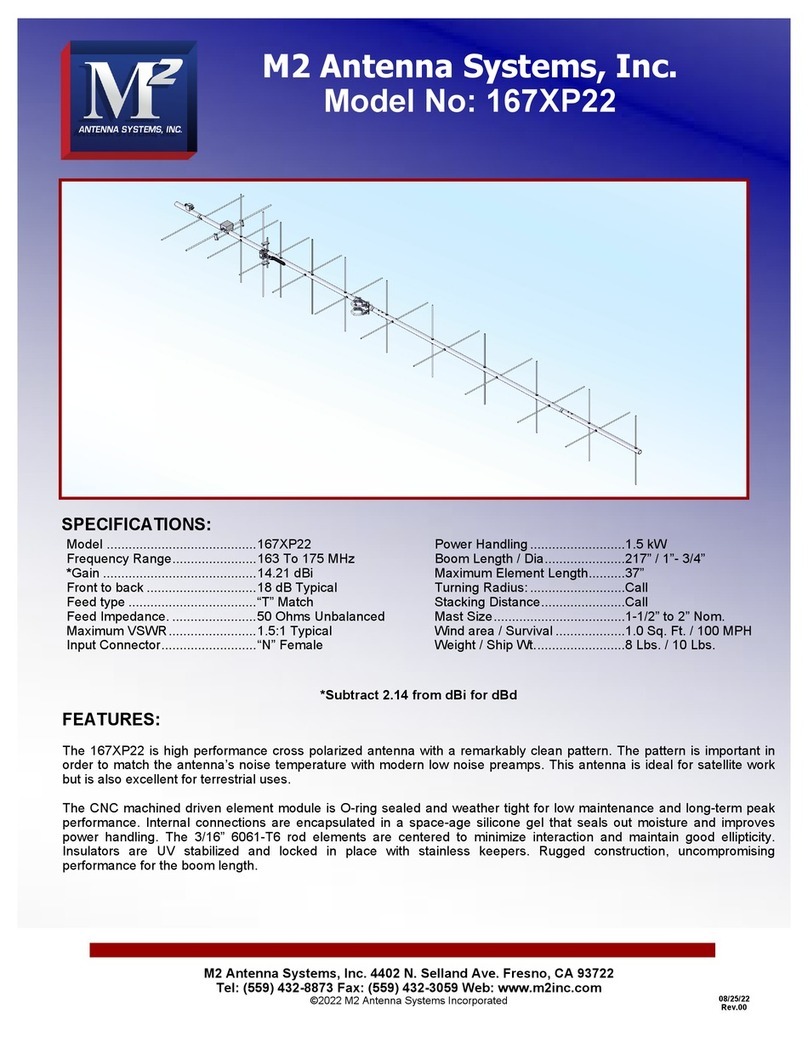

M2 Antenna Systems 167XP22 User manual

M2 Antenna Systems

M2 Antenna Systems SYSTEM SAMPLE 3 User manual

M2 Antenna Systems

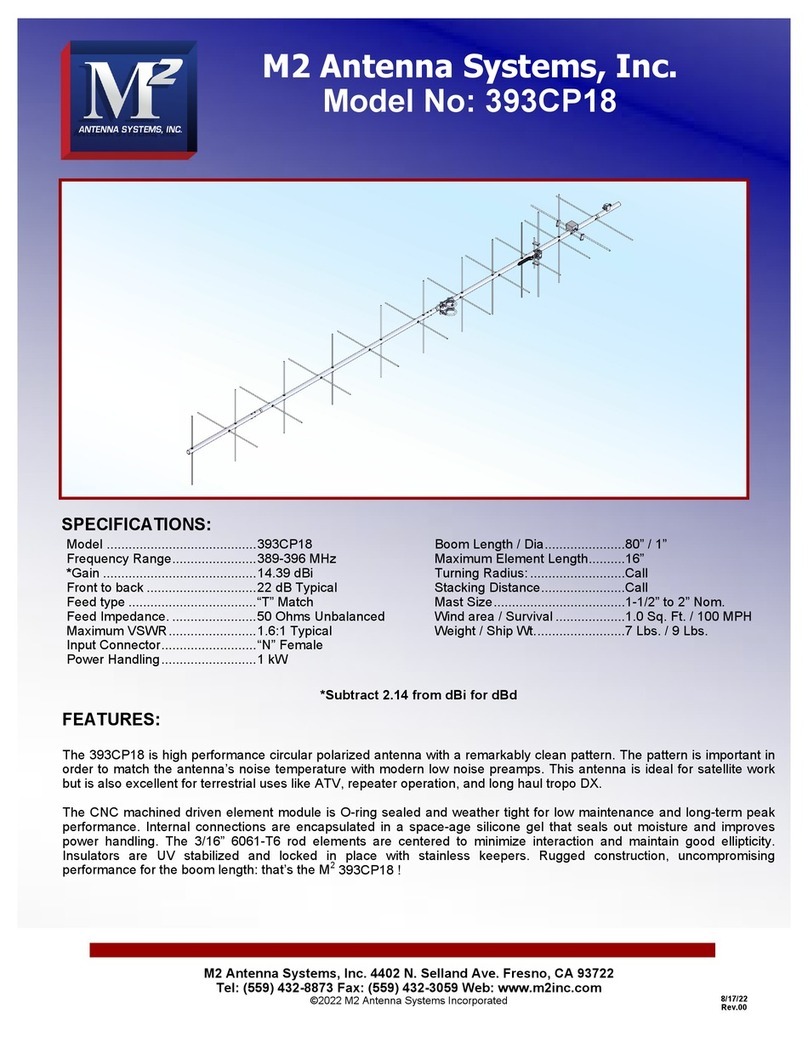

M2 Antenna Systems 393CP18 User manual

M2 Antenna Systems

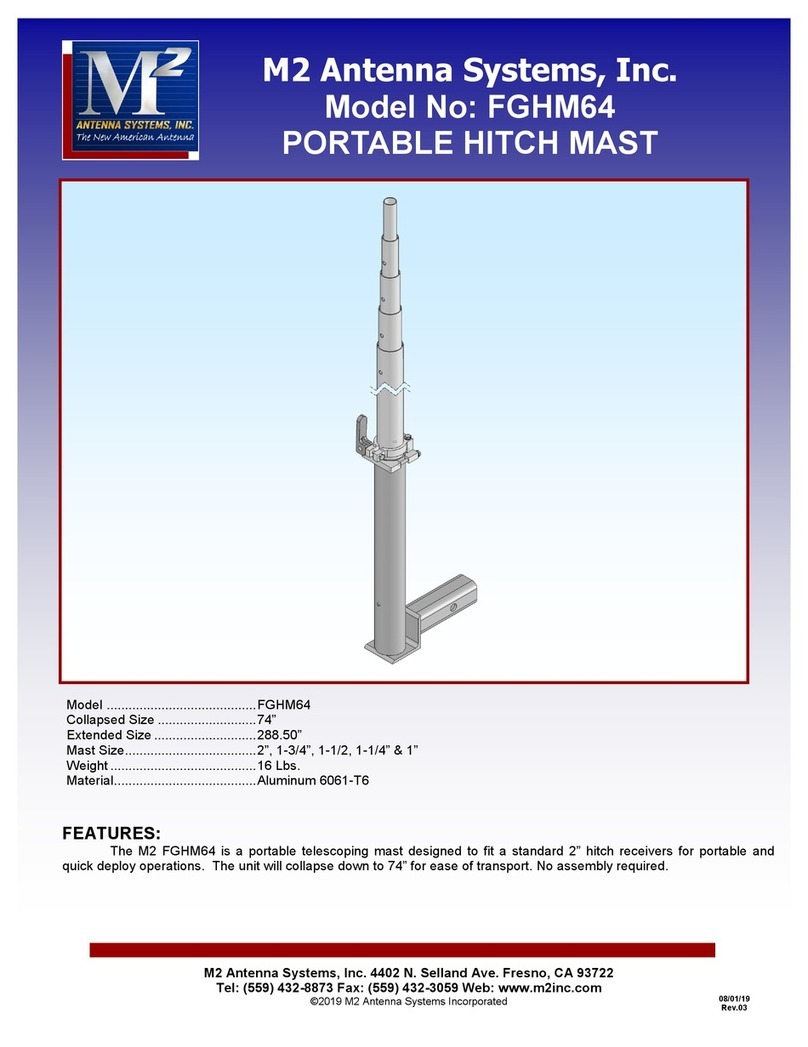

M2 Antenna Systems FGHM64 User manual

M2 Antenna Systems

M2 Antenna Systems 40M3C User manual

M2 Antenna Systems

M2 Antenna Systems FGSD-2.4DH User manual

M2 Antenna Systems

M2 Antenna Systems DCN100-500 User manual

M2 Antenna Systems

M2 Antenna Systems 146CP8 User manual

M2 Antenna Systems

M2 Antenna Systems 248CP22A User manual

M2 Antenna Systems

M2 Antenna Systems 1700-26-2 User manual

M2 Antenna Systems

M2 Antenna Systems 6M5XHG User manual

M2 Antenna Systems

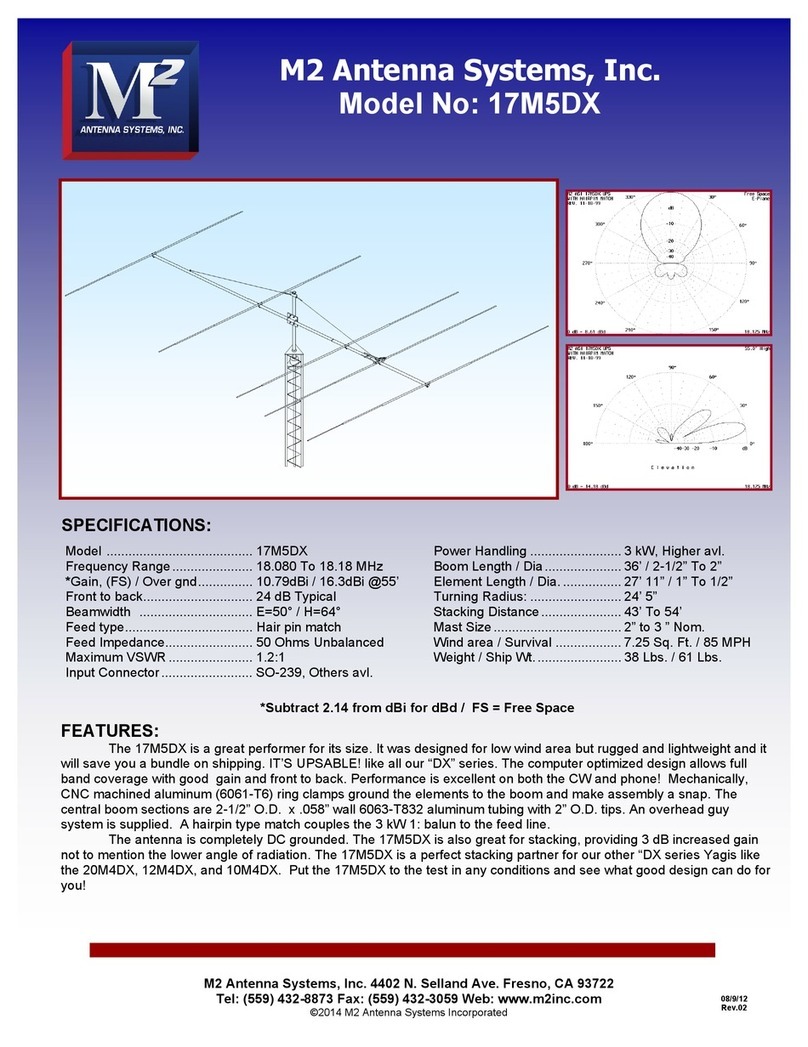

M2 Antenna Systems 17M5DX User manual

Popular Antenna manuals by other brands

Alfa Network

Alfa Network APA-L01 Specifications

Naval

Naval PR-422CA Operation manual

Feig Electronic

Feig Electronic ID ISC.ANTH200/200 Series manual

TERK Technologies

TERK Technologies TV44 owner's manual

Directive Systems & Engineering

Directive Systems & Engineering DSE2324LYRMK quick start guide

HP

HP J8999A instructions

CommScope

CommScope CMAX-OMFX-43M-I53 Installation instruction

Ramsey Electronics

Ramsey Electronics DAP25 Kit assembly and instruction manual

COBHAM

COBHAM SAILOR 800 VSAT Replacement procedure

Trango Systems

Trango Systems AD900-9 Specification sheet

Steren

Steren ANT-100 user manual

IWCS

IWCS iriBelt II Quick start user guide