Index

Index .................................................................................................................................................................................................................. 2

Chapter 1 Safety Precautions................................................................................................................................................................. 3

Chapter 2 Overview .................................................................................................................................................................................... 5

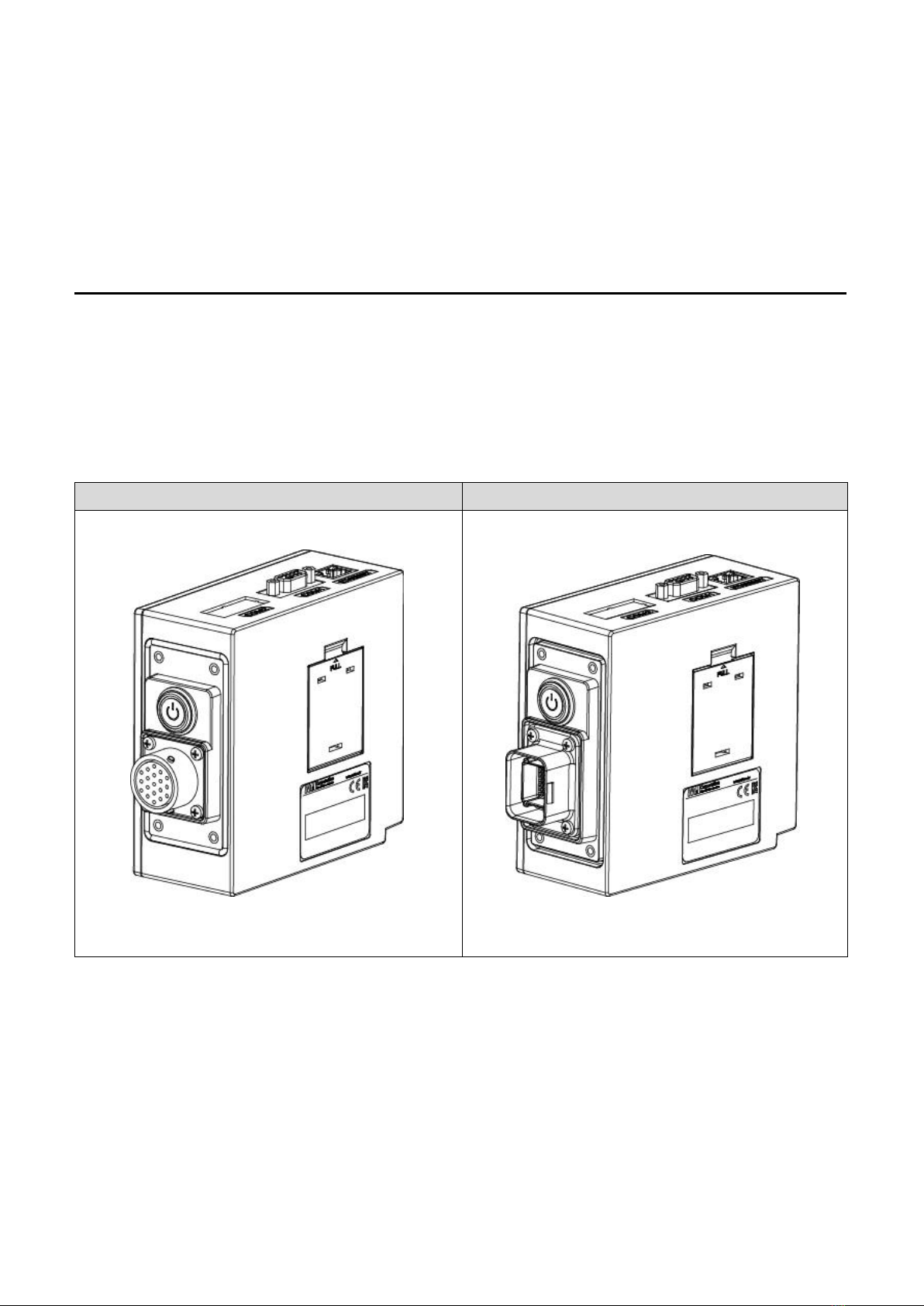

2.1 Product Introduction....................................................................................................................................................... 5

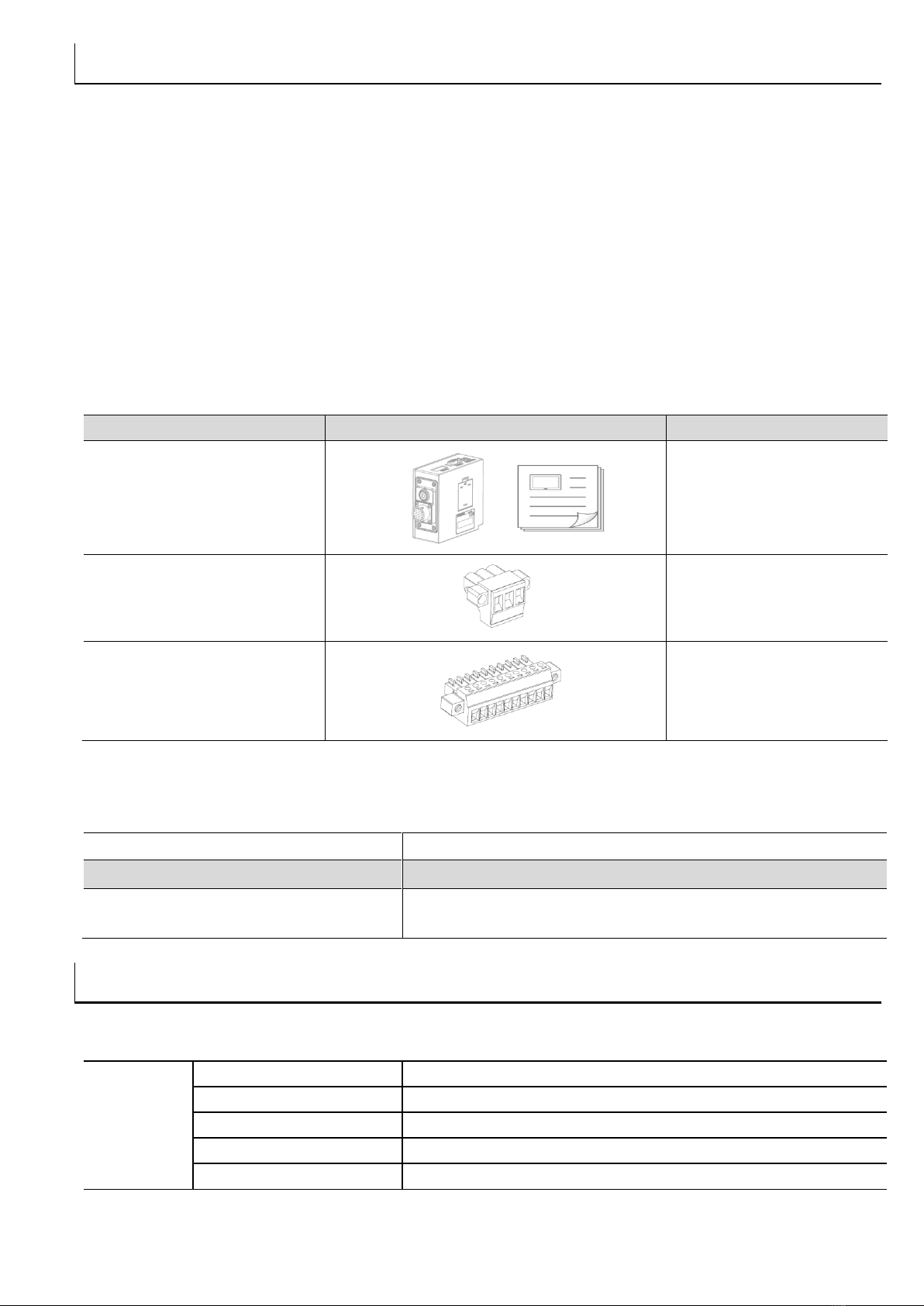

2.2 Components........................................................................................................................................................................ 5

2.3 Model Name Description ............................................................................................................................................. 5

Chapter 3 General Specifications ......................................................................................................................................................... 5

3.1 Power Specifications ....................................................................................................................................................... 5

3.2 Environment Specifications.......................................................................................................................................... 6

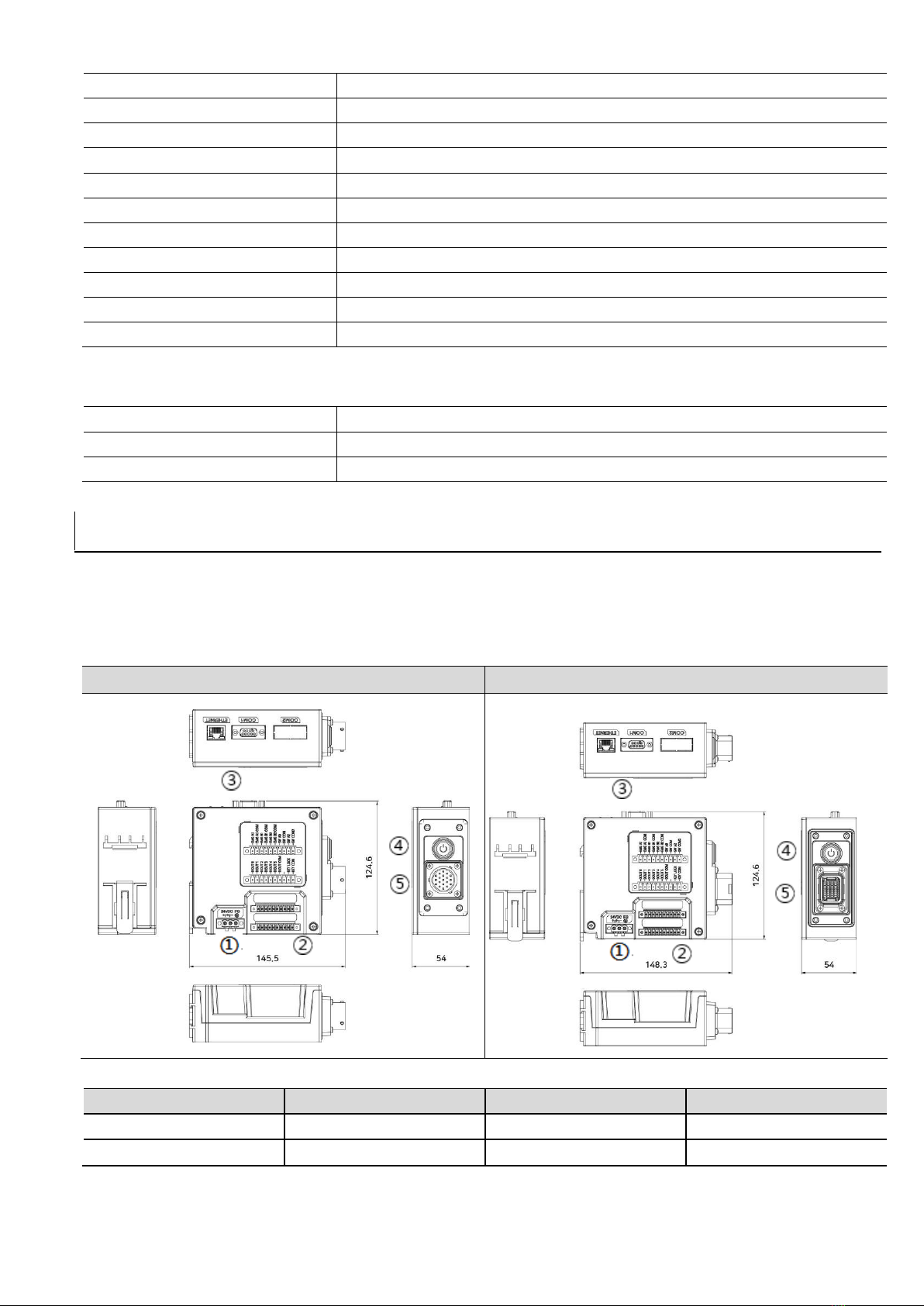

3.3 Structure Specifications ................................................................................................................................................. 6

Chapter 4 Parts and Detail Specifications........................................................................................................................................ 6

4.1 TOPRHWS Series............................................................................................................................................................... 6

Chapter 5 Interface with Other Devices............................................................................................................................................ 7

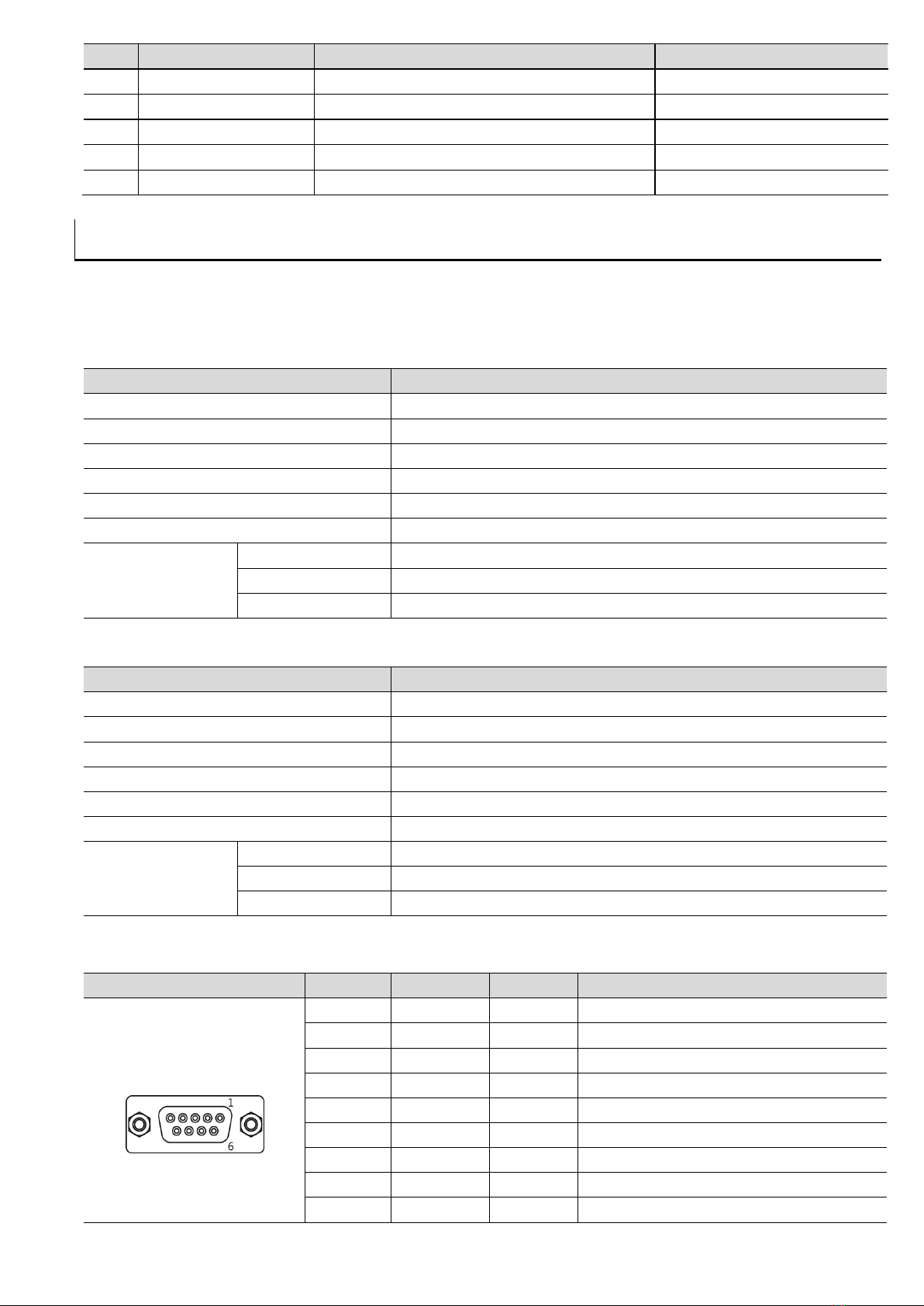

5.1 Serial Communication Specifications ...................................................................................................................... 7

5.2 Ethernet Communication Specifications ................................................................................................................ 8

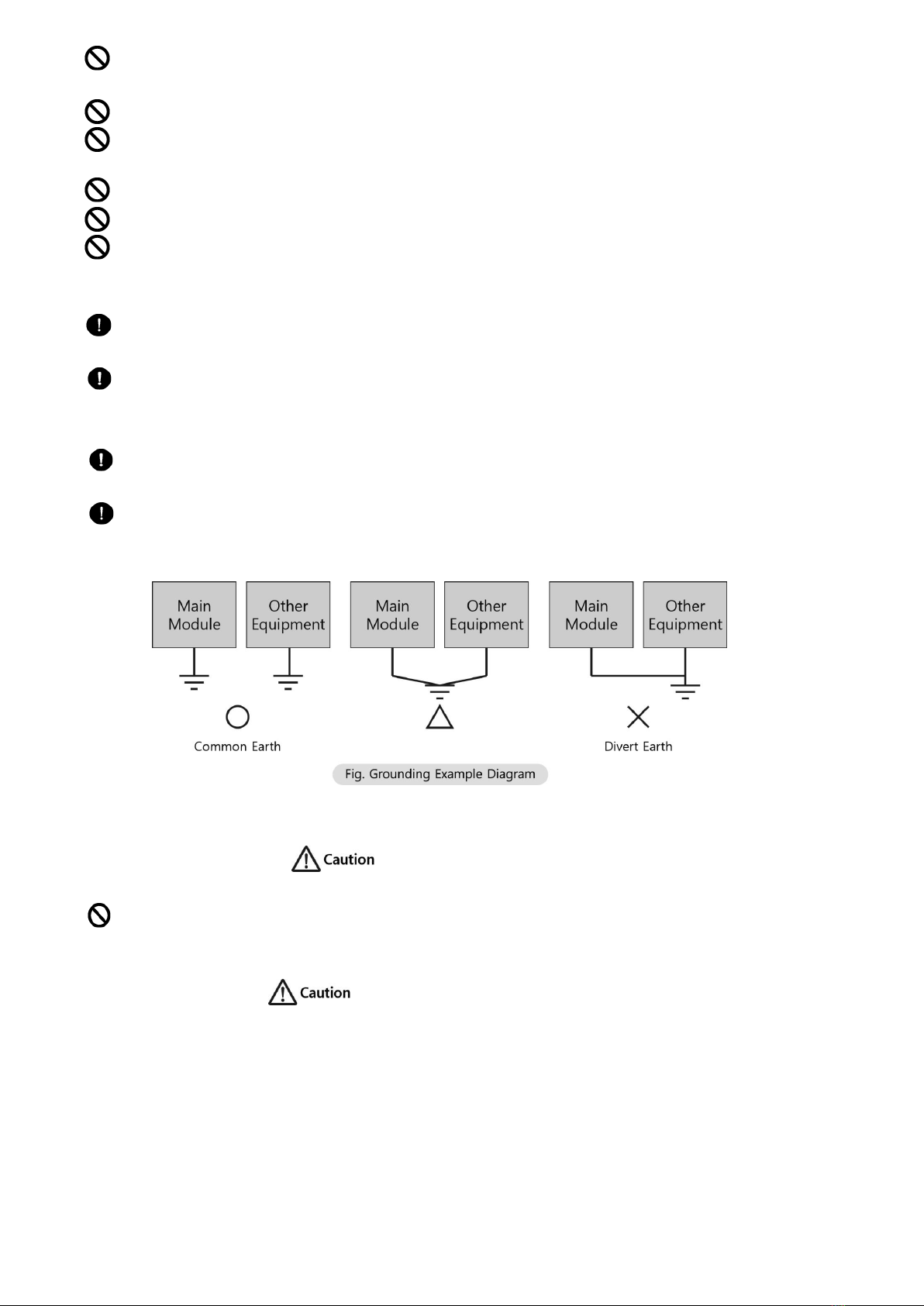

Chapter 6 Block Diagram for Installation......................................................................................................................................... 9

6.1 Connection Diagram....................................................................................................................................................... 9

6.2 Panel Cut Size for Front Panel Installation.........................................................................................................10

6.3 Cable Diagram .................................................................................................................................................................10

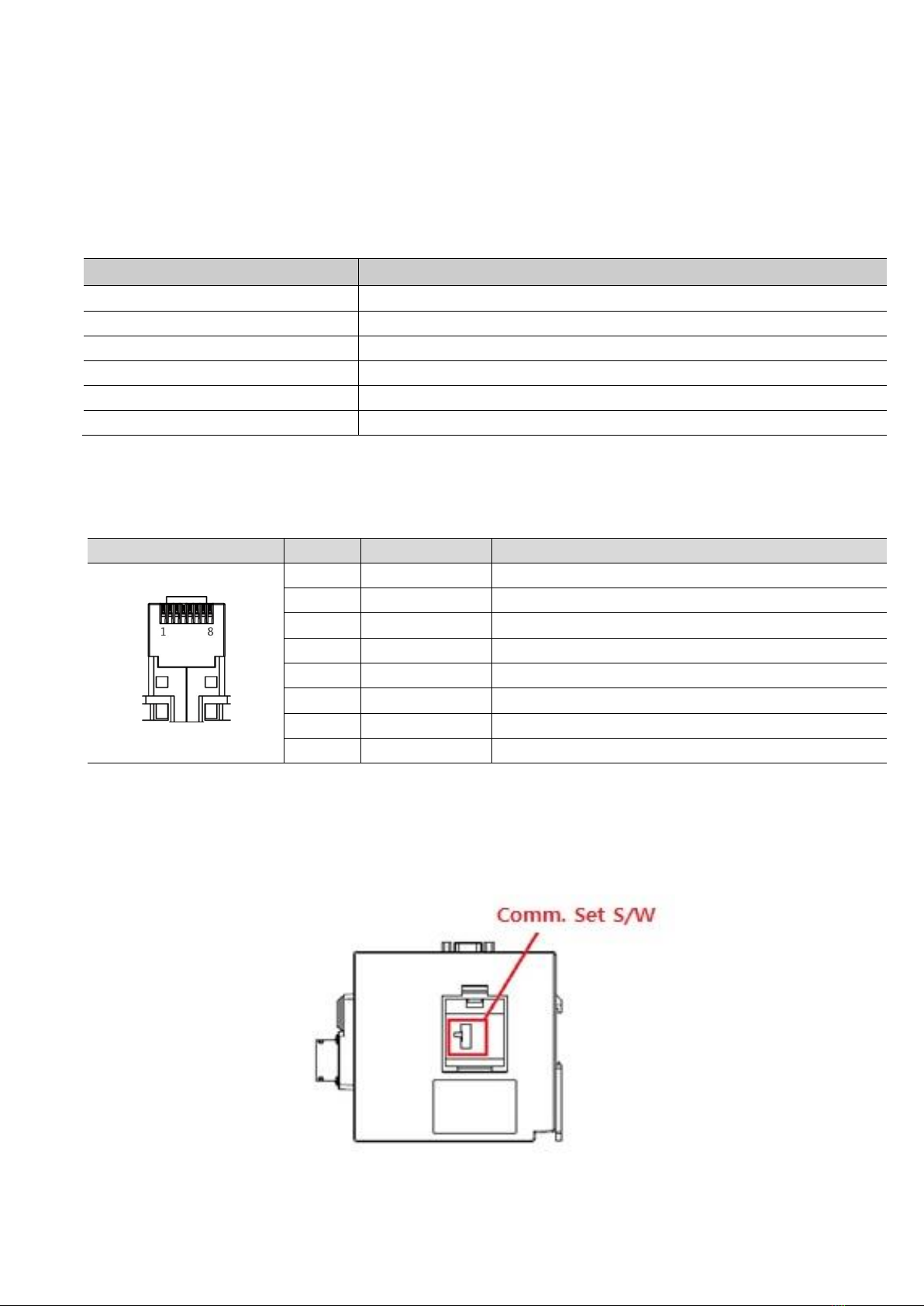

6.4 Mechanical Switch Setting of TOPRH0700WD FE Main Body ..................................................................13

6.5 Serial and Ethernet Communication Setting Switch......................................................................................13

6.6 The Purpose and examples of External Functions..........................................................................................13

Chapter 7 Installation and Wiring......................................................................................................................................................17

7.1 Selecting installation Location..................................................................................................................................17

7.2 Connection of the Cable Pack to the Main Body ...........................................................................................17

7.3 Power Wiring....................................................................................................................................................................17

Chapter 8 Maintenance ..........................................................................................................................................................................18

8.1 Surface Cleaning .............................................................................................................................................................18

8.2 Regular Inspection .........................................................................................................................................................18

8.3 Problems with the Product ........................................................................................................................................18

Chapter 9 Warning Label.......................................................................................................................................................................19

Chapter 10 Product Label......................................................................................................................................................................19