Service Engineering

- 9

Unpacking your dryer

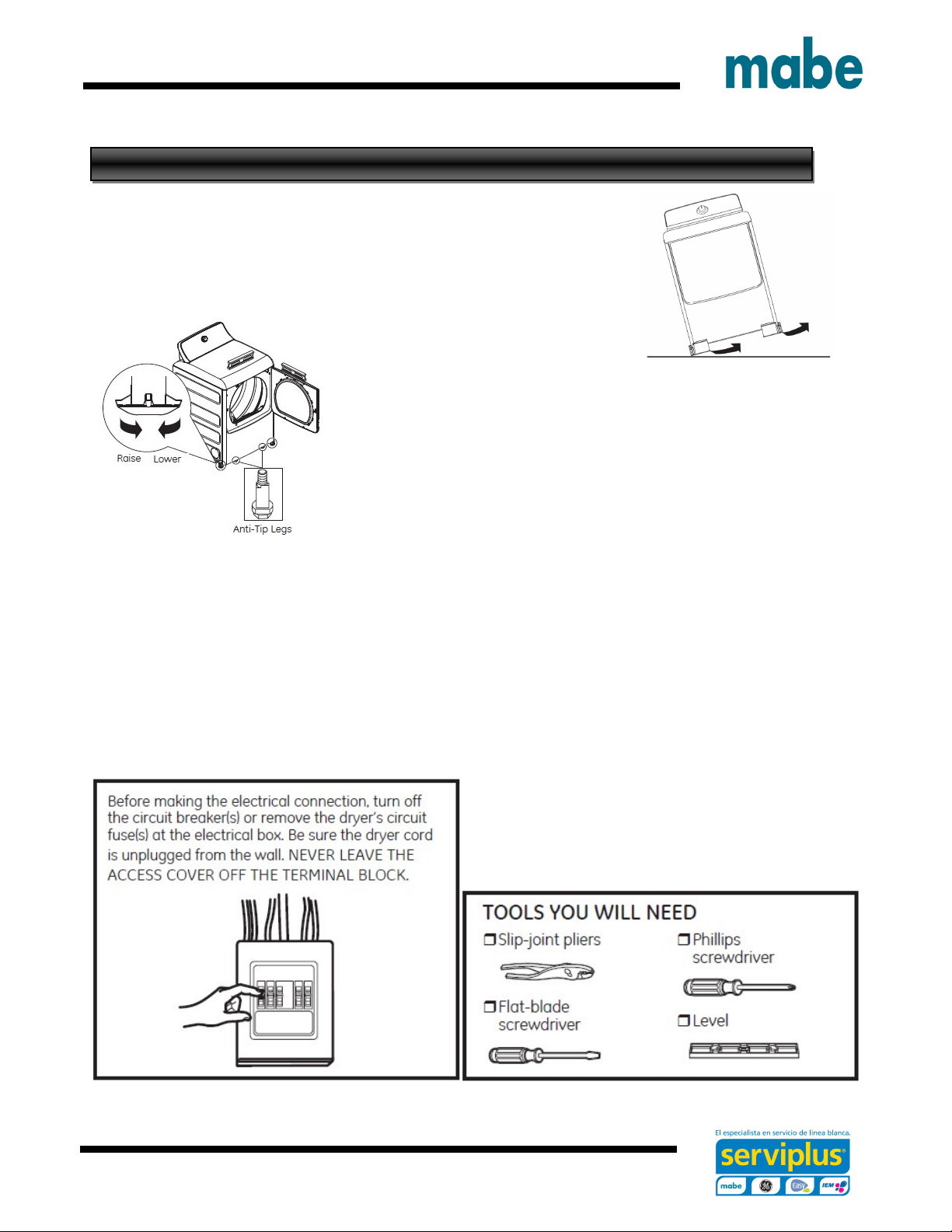

• Tilt the dryer sideways and remove the foam shipping pads by pulling at the

sides and breaking them away from the dryer legs. Be sure to remove all of

the foam pieces around the legs. Remove literature and bag containing

accessories.

• Place the Dryer at designated area.

Stand the dryer upright near the final location and adjust the leveling legs at

the corners to ensure the dryer is level side-to-side and front-to-back. Then,

adjust the two anti-tip legs at the front inner corners, taking care that they are

touching the floor to avoid unit tip over. The installation is not complete until

this process is finished.

Warning: to avoid the risk of ignition and personal injury:

This dryer must be exhausted to the outdoors.

Before the old dryer is removed from service or discarded, remove the dryer door.

Service information and the wiring diagram are located in the control console.

The vent duct material MUST BE METAL.

This dryer must be grounded. In the event of a malfunction or breakdown, grounding will reduce the risk

of electric shock by providing a path of least resistance for electric current.

Install the dryer where the temperature is above 10°C for satisfactory operation of the dryer control

system.

Remain the area beneath and around the dryer without flammable substances as lint, paper, solvents,

chemicals, gasoline or other flammable liquids.

The exhaust vent MUST be securely fastened to a non-combustible portion of the mobile home.