REV A IN M02S006M-02

Page 2of 2

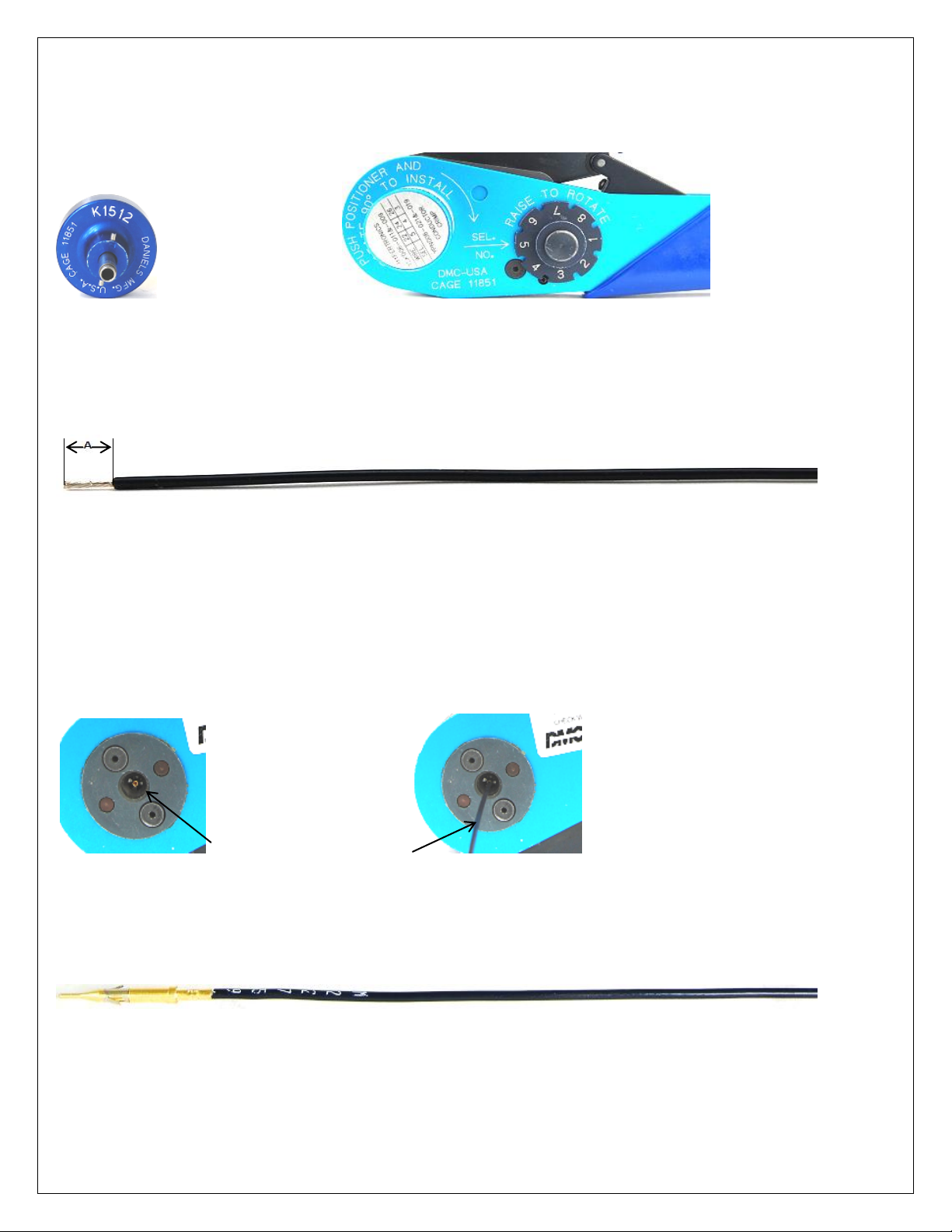

STEP 2) Insert the Positioner into the Crimp Tool and rotate until the two Location Pins lock in place by

pushing the positioner and rotating as shown in Fig. C. and D. below.

Fig. C. (Positioner) Fig. D. (Positioner inserted into Crimp Tool)

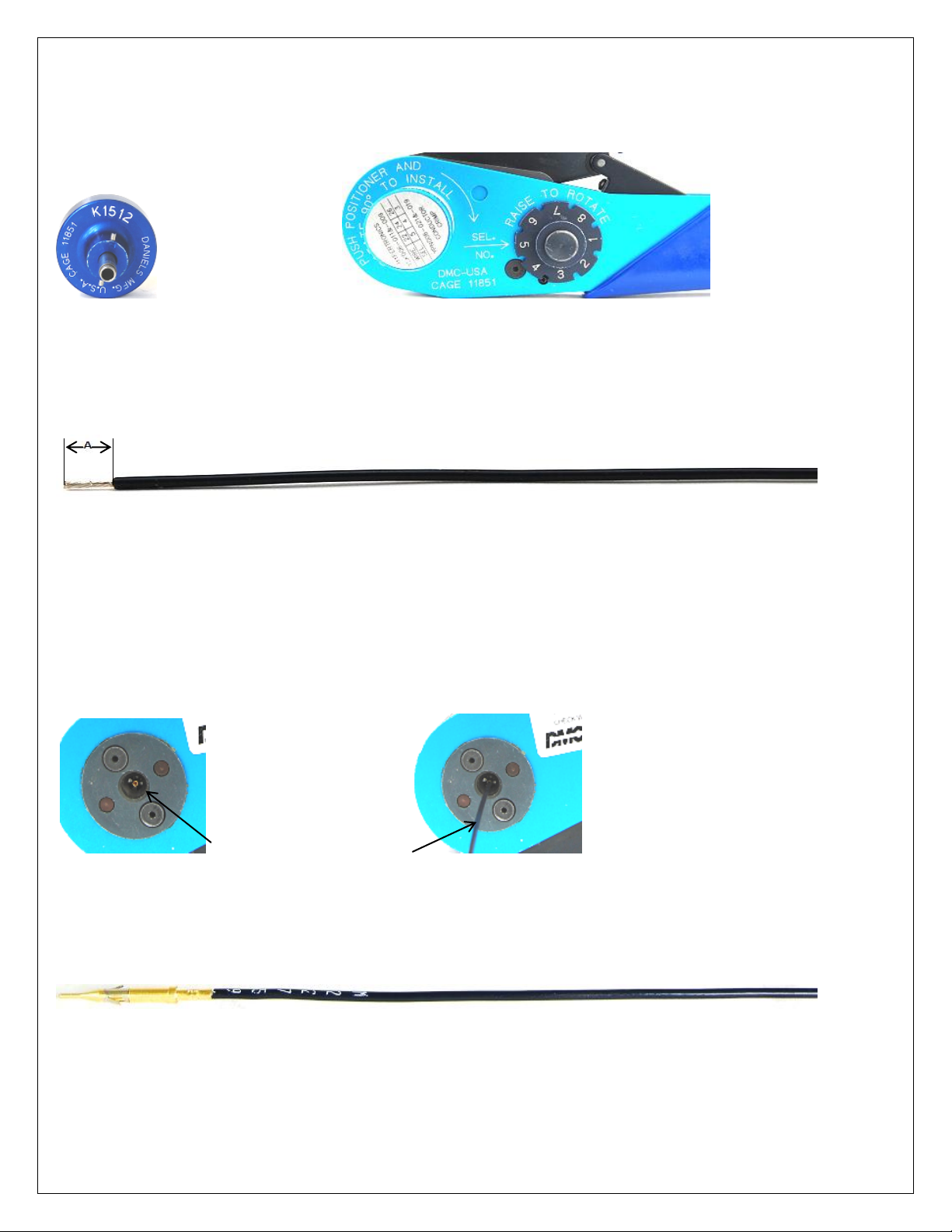

STEP 3) Strip wire to dimensions in “Contact Crimp Information” Table using a ruler along with a wire stripper

as shown in Fig. E.

Fig. E

STEP 4) Turn the Selector Knob to suit the size of wire to be crimped, (per “Contact Crimp Information Table”

above).

NOTE: Crimp Tool Settings are based on Military Specifications Wire M22759/11xx Standard. Adjust settings to

suit other Specifications.

STEP 5) Place Contact into Positioner. Insert Stripped end of wire into Contact and crimp as in Fig. F and G.

Contact Wire

Fig. F. (Contact in Positioner) Fig. G. (Wire in inserted in Contact)

STEP 6) Inspect crimped assembly for extruding strands of wire to prevent shorts and also check for retention

by a Pull and Return Test per IPC/WHMA-A-620A standard (Ch. 19.7.2) to match Fig. G. below.

Fig. G.