MacDonald Steel Limited

BREWERY SYSTEMS DIVISION

4 REV 00

CONTROLS

POWER ON/OFF

Side panel – main power to machine. Circuit breaker(s) are also located directly below the power

switch. When tripped a visible red line appears on the breaker button. Also inside the machine on

the terminal blocks are fuse(s) which protect the PLC outputs and fuse(s) protecting the 24 VDC

power supply.

STOP SWITCH

(Red) Stops all operations on all heads. All heads lift and shuttle forward. This switch also acts

as a master reset switch. At any time if held for 2 seconds, the heads and door will rise, and the

shuttles return to the front position.

On multi-head machines, there is a stop switch for each head on the Human Machine Interface

(HMI), which allows independent heads to be stopped.

START SWITCH

(Green) When pushed the door will go down and the machine will begin the selected cycle.

MANUAL STOP SWITCH:

These stop switches are accessed via the HMI display. When the HMI main screen is being

displayed, the stop buttons will stop each bottle independently. Pushing the stop button a second

time will lift the head immediately.

MANUAL CROWN SWITCH:

These crown switches are accessed via the operator display. When the HMI main screen is

being displayed there is a button for each crowner.

ANALOG PRESSURE TRANSDUCERS

One for each head, these switches control the pressure for the Co2 pressure and the vacuum

draw.

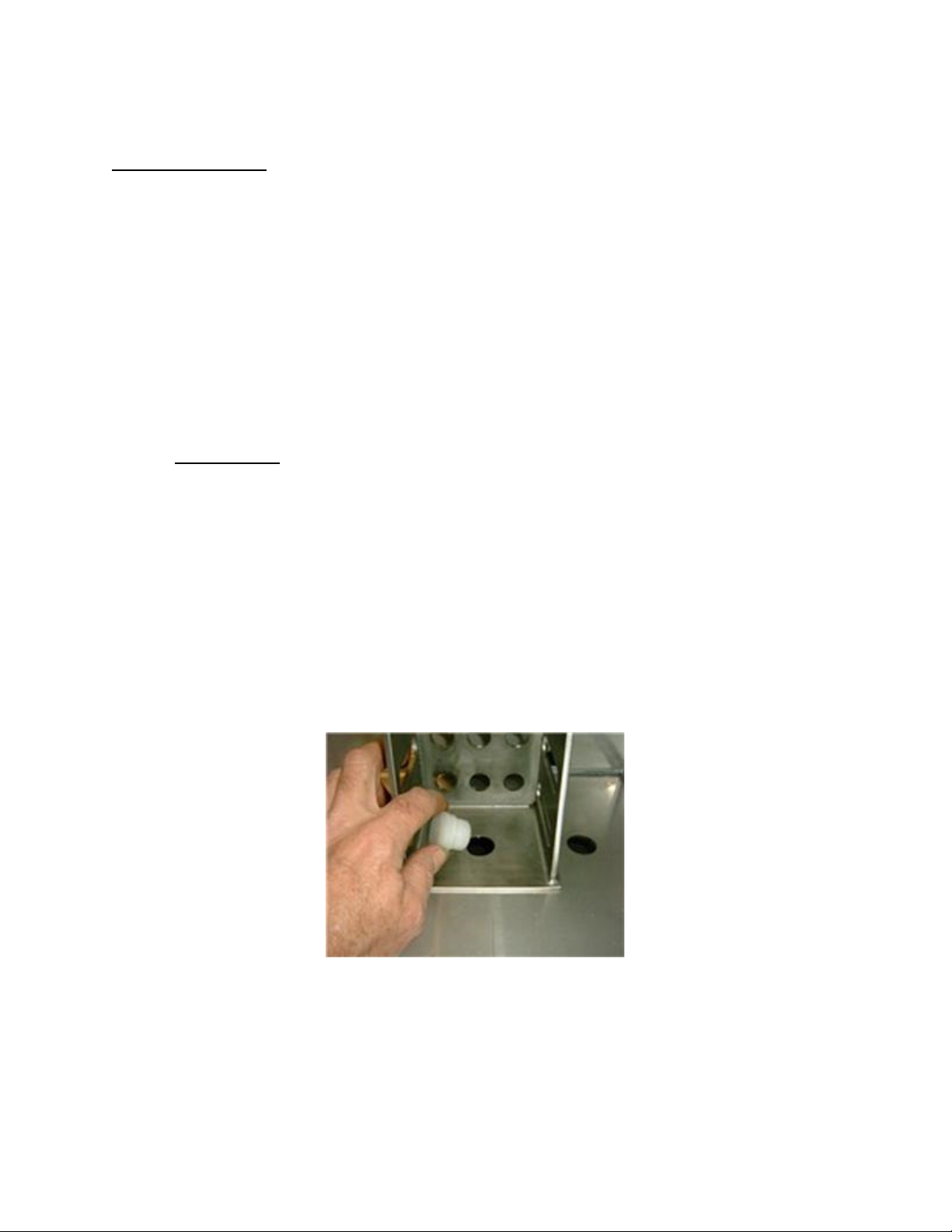

VENT CONTROL

Stainless steel flow controls, one for each head, located at the lower left side of the machine.

These control the rate of pressure released from the bottle and thus the fill rate of beer.

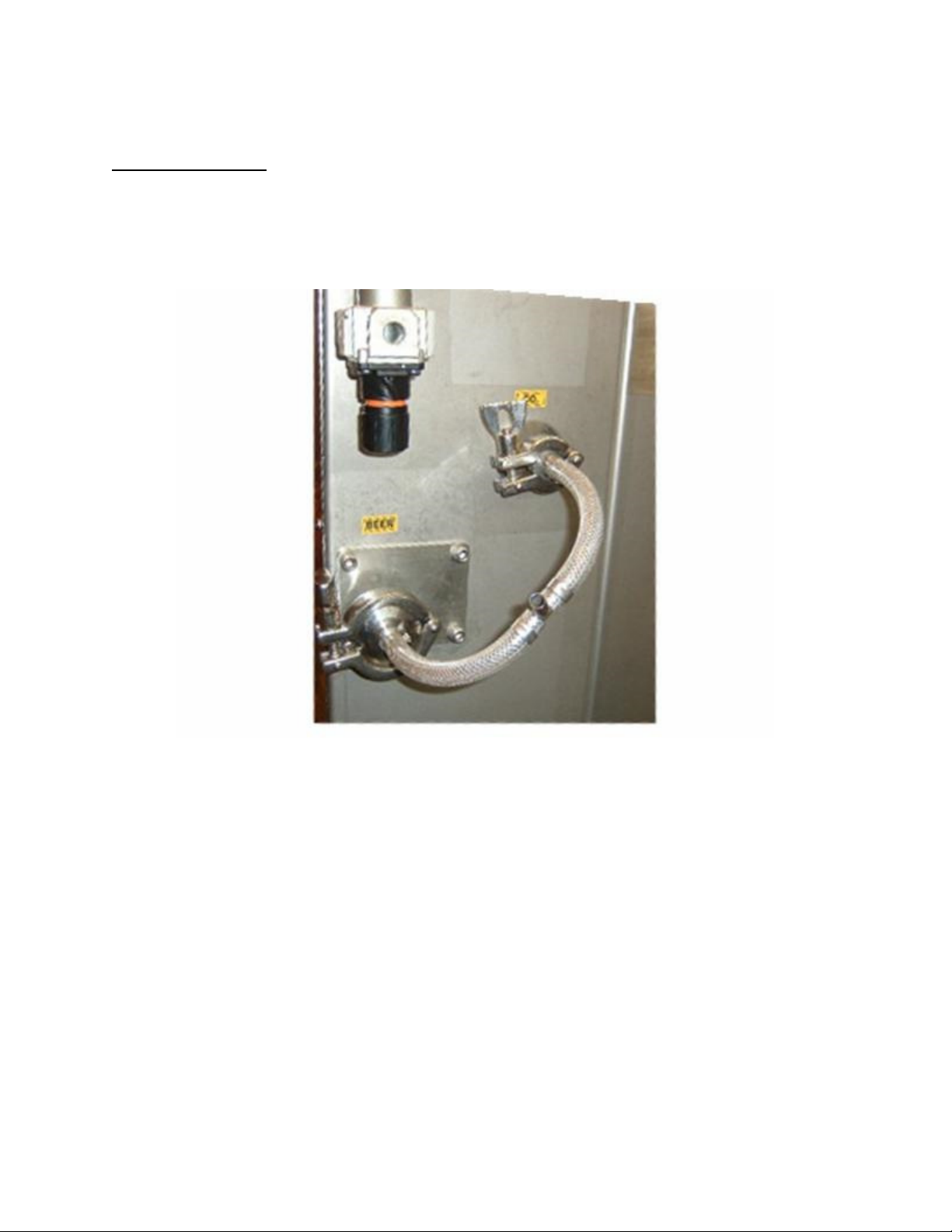

AIR REGULATOR

Set the regulator to 60 psi as a starting point. The crowning cylinders require the most force and

the pressure may have to be increased to ensure a good crown. The vacuum is a venturi style

and uses air to achieve vacuum. If you require a deeper vacuum you may have to increase the

air pressure as well. The air components in the machine should not be exposed to water or oil,

install a good quality filter before the machine. The maximum air pressure should not exceed 90

psi. The lower the pressure the longer life expectancy of the air components.

Co2 REGULATOR

The Co2 regulator (not supplied) is to be set dependant on the pressure in the beverage supply

tank. When the EZ Pressure set up measures the tank pressure the Co2 counter pressure is

automatically set to 2 psi higher than the tank reading. The set point value is displayed on the

bottom of the pressure screen when the Co2 valve is opened. The Co2 regulator must be able to

achieve that value. It is recommended to set the regulator between 5 to 10 psi higher than the

tank pressure. Setting the regulator too high could result in false or unstable measurements as

the valve opens and Co2 surges into the pressure transducer.