6

Mactrap Grease Boss Operational Manual v Feb 2017

Warranty: A 12 month warranty applies to parts and materials for this MACTRAP GRU. This warranty does

not include any labour, cleaning out or maintenance. If the MACTRAP GRU is not installed and operated as per

these operation guidelines, the warranty will be void.

GETTING STARTED

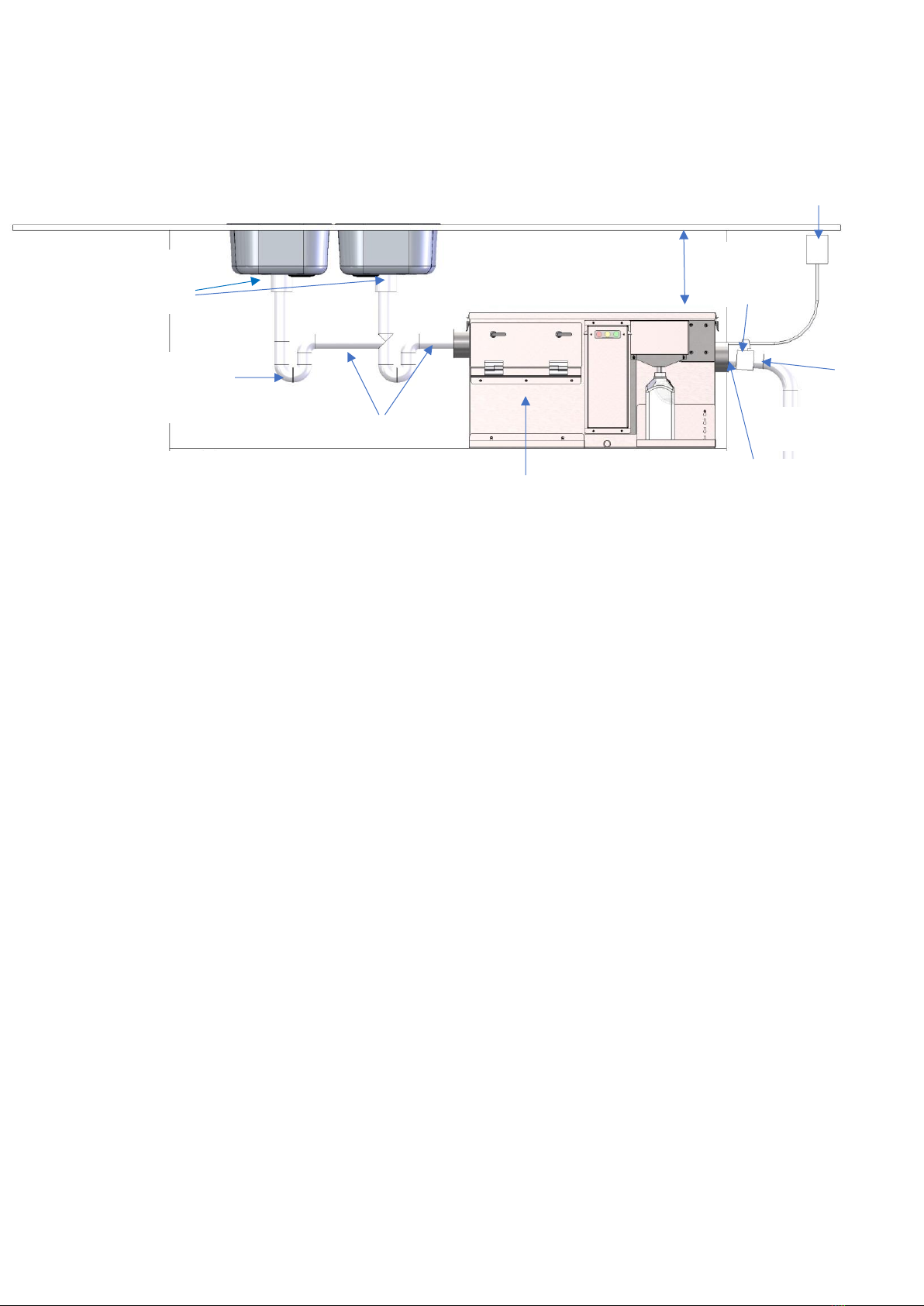

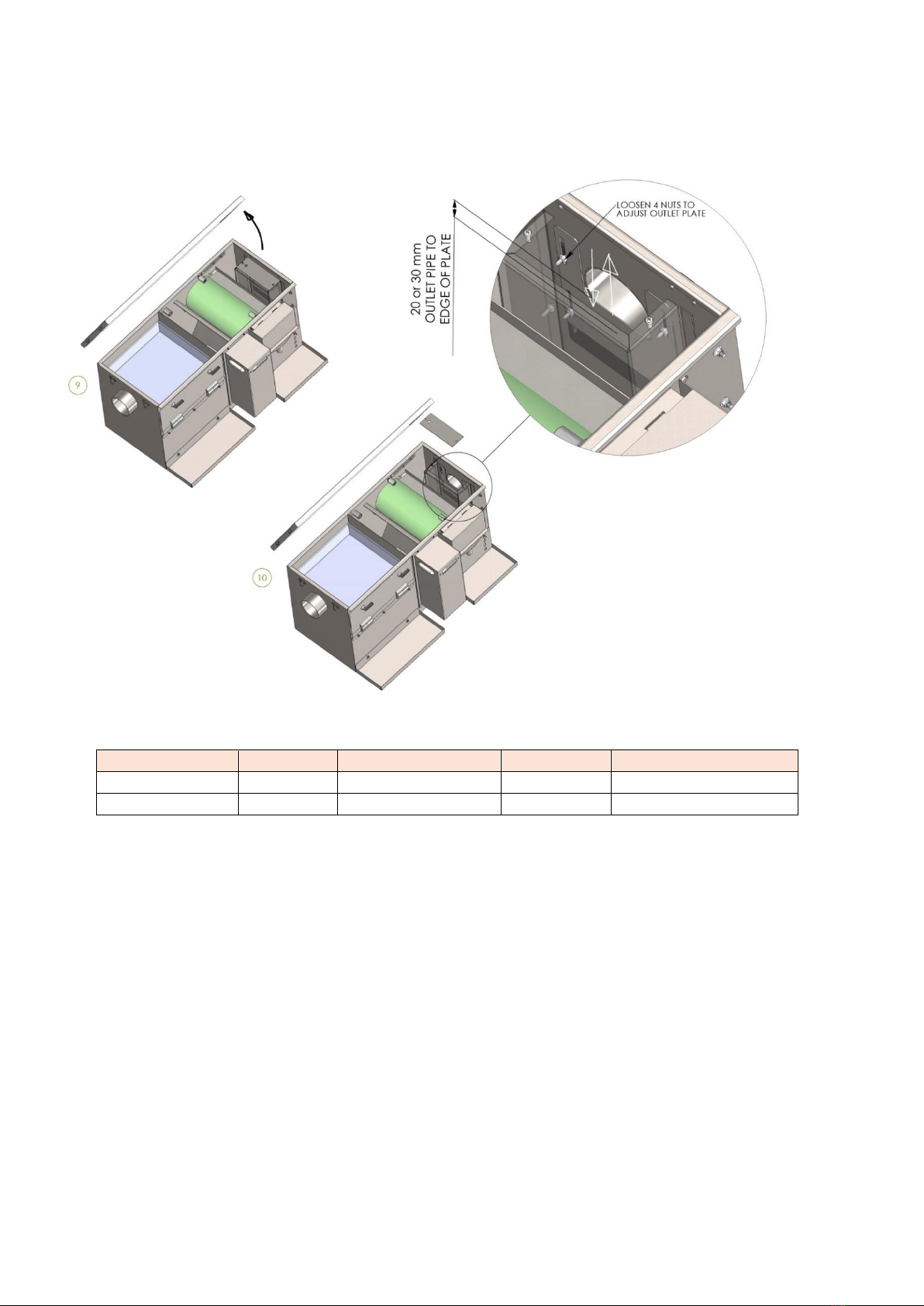

Step 1 Check the unit is plumbed in correctly (and that all parts can be accessed)

Step 2 Fill unit with water

Step 3 Connect to electric supply (via a 30 ma residual current device)

Step 4 Switch power on at mains (the orange light will indicate that power is on).

The unit will be programmed so there is no need to set the timer and

cycle programmes. The red light should be flashing. This means the unit

is working.

Step 5 Carry out all housekeeping requirements outlined in this manual

Always turn off power prior to removing wiper or roller units, and if opening electrical cover

ATTENTION

-NEVER TURN ON WHEN EMPTY. THE HEATING ELEMENT MAY OVERHEAT

-UNIT REQUIRES DAILY HOUSEKEEPING BY REMOVING FOG

-DO NOT LET FAT OR SOLIDS BUILD UP ON HEATING ELEMENT

-SERVICE CONTRACTS BY APPROVED ENGINEER ARE AVAILABLE AND RECOMMENDED

-UNIT WILL LOSE EFFICIENCY IF NOT MAINTAINED AS SOLIDS WILL BUILD UP INSIDE

-THE GREASEBOSS IS DESIGNED TO TRAP AND REMOVE FREE FLOATING GREASE OILS AND FATS.

-THE SOLIDS BASKET PROVIDED PROTECTS THE UNIT FROM SOLID FOOD WASTE BUILD UP. TO HELP ENSURE THE

HIGHEST EFFICIENCY, REDUCE SOLID FOODWASTE BY INSTALLING PRIMARY SINK STRAINERS OR BY SCRAPING WASTE

INTO BINS.

-CONSULT YOUR SUPPLIER IN THE EVENT OF INCREASED LOADINGS TO THE GREASEBOSS

- DO NOT USE HARMFUL DETERGENTS TO CLEAN GREASEBOSS

Due to the many possible factors affecting hardness of water used by customers and regional differences of water

hardness, Mactrap and their supplier of the heating element cannot guarantee the lifetime of any element and

elements are therefore not included in our warranty statement.