Getting Started..................................................................................................................................................5

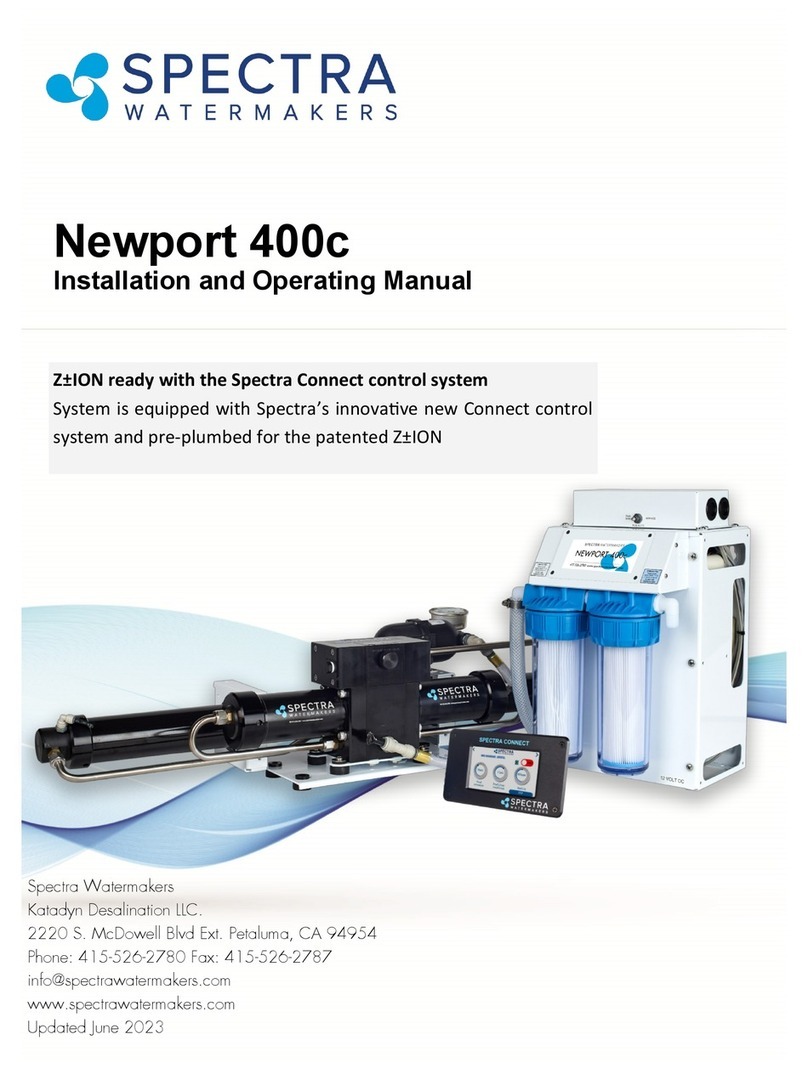

Installation Basics.............................................................................................................................................6

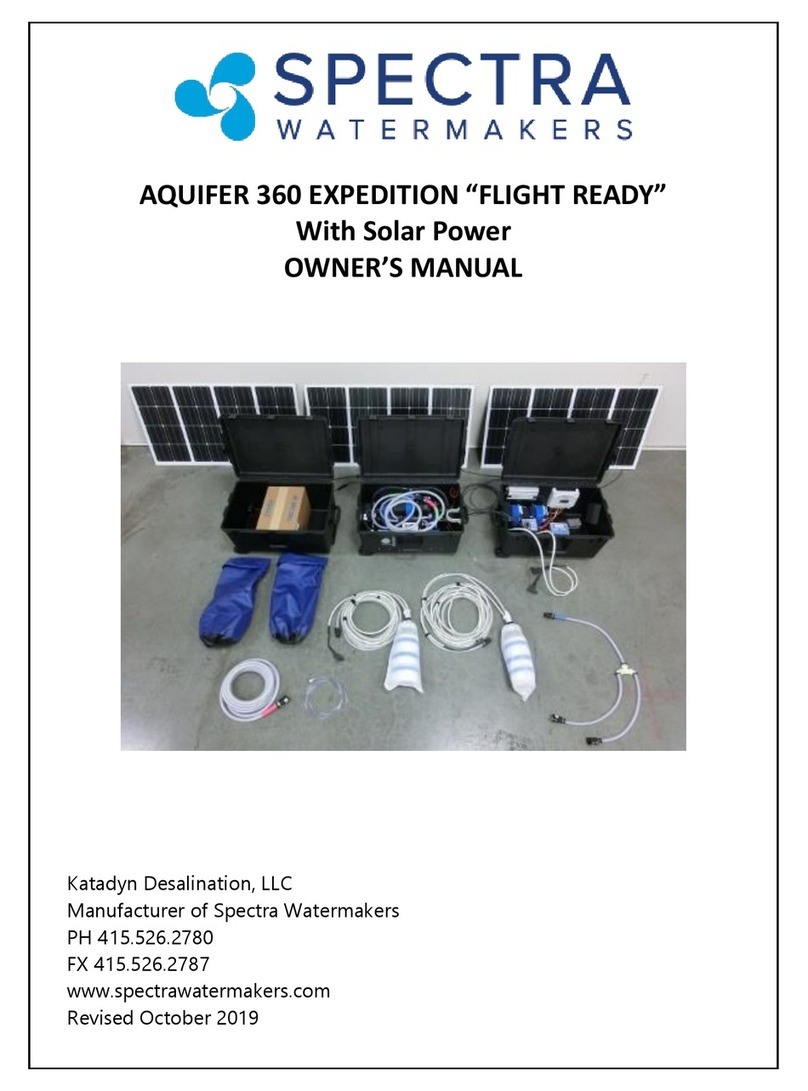

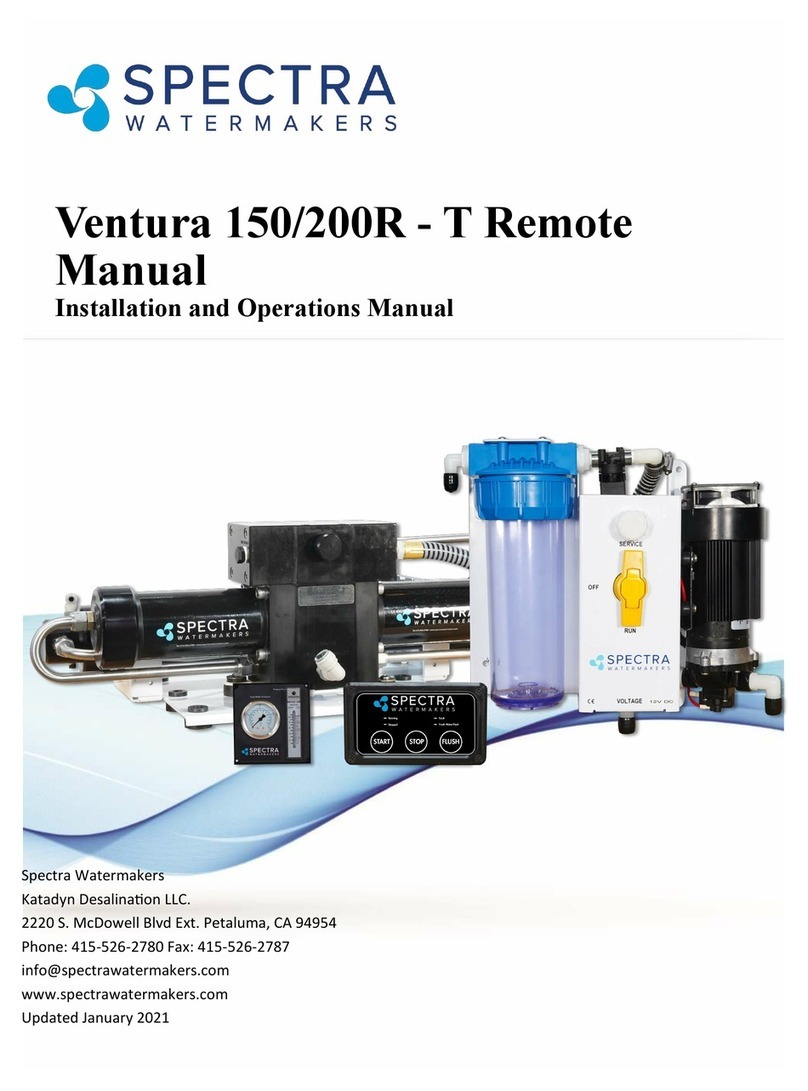

Component Placement......................................................................................................................................7

Plumbing ........................................................................................................................................................10

Parker Tube Fitting Assembly Procedure......................................................................................................14

John Guest Super Speedfit.............................................................................................................................15

Wiring.............................................................................................................................................................16

MPC Tank Switch Wiring and operation.......................................................................................................21

Membrane Pressure Vessel Relocation ..........................................................................................................39

Z Brane Installation........................................................................................................................................49

Table of Contents

Part 1

Installation

Operation

Page Number

New Systems Start Up and Testing................................................................................................................ 23

Dry Testing..................................................................................................................................................... 26

Normal Start Up Using the Auto Run ............................................................................................................27

Automatic Fresh Water Flush Cycle ..............................................................................................................28

Manual Operation...........................................................................................................................................30

Long Term Storage Procedures......................................................................................................................31

Winterizing..................................................................................................................................................... 33

Maintenance ...................................................................................................................................................34

Membrane Cleaning .......................................................................................................................................35

Salinity Probe Calibration..............................................................................................................................37

Suggested Spares............................................................................................................................................38

Newport Troubleshooting Procedures............................................................................................................ 41

Bulletins..........................................................................................................................................................43

Wiring.............................................................................................................................................................53

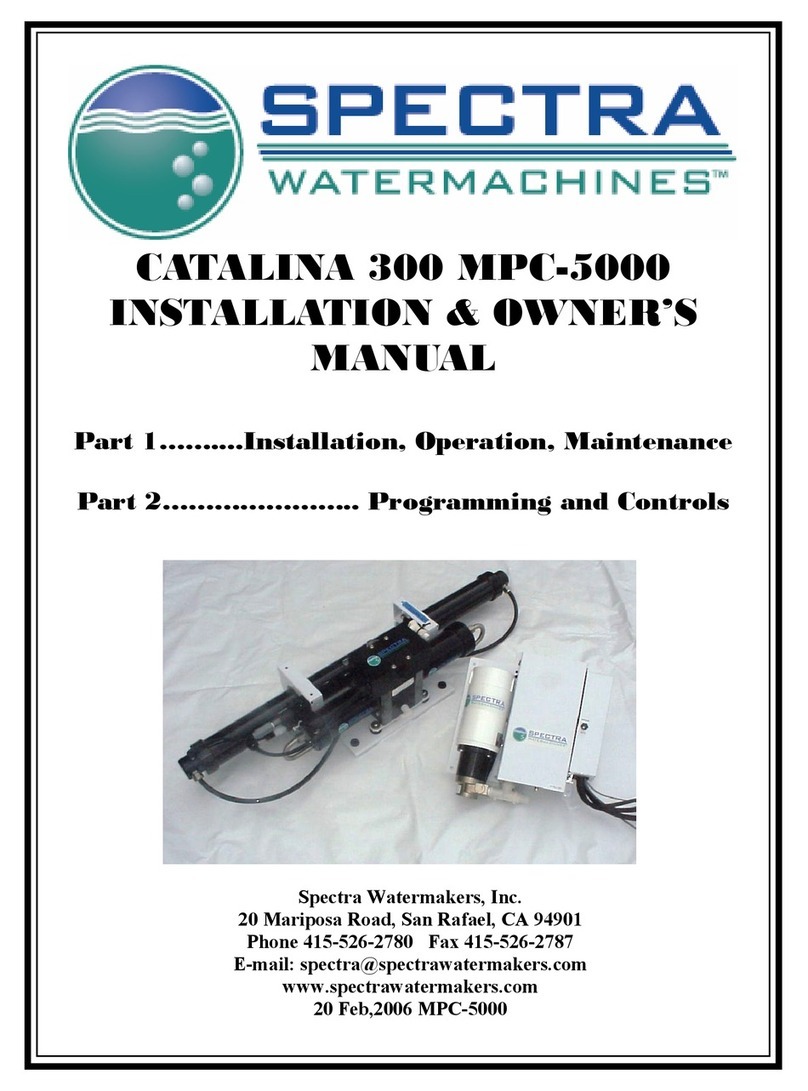

Clark Pump.....................................................................................................................................................54

Parts List.........................................................................................................................................................59

Service & Maintenance

Part 2 Controls

Section 2: Programming & Controls

Begins after pg 62