Imbrium Stormceptor EF User manual

EF

Owner's Manual

2Stormceptor ® EF Owner's Manual

STORMCEPTOR®EF IS PATENT-PENDING.

TABLE OF CONTENTS

• STORMCEPTOR EF OVERVIEW

• STORMCEPTOR EF OPERATION AND COMPONENTS

• STORMCEPTOR EF MODEL DETAILS

• STORMCEPTOR EF IDENTIFICATION

• STORMCEPTOR EF INSPECTION AND MAINTENANCE

• STORMCEPTOR CONTACTS

3

Stormceptor ® EF Owner's Manual

OVERVIEW

The Stormceptor ® EF is a continuation and evolution of the most globally recognized oil-grit separator

(OGS) stormwater treatment technology - Stormceptor ®. Also known as a hydrodynamic separator,

the enhanced ow Stormceptor EF is a high performing oil-grit separator that effectively removes a

wide variety of pollutants from stormwater and snowmelt runoff at higher ow rates as compared to the

original Stormceptor. Stormceptor EF captures and retains sediment (TSS), free oils, gross pollutants and

other pollutants that attach to particles, such as nutrients and metals. Stormceptor EF’s patent-pending

treatment and scour prevention technology and internal bypass ensures sediment is retained during all

rainfall events..

Stormceptor EF offers design exibility in one simplied platform, accepting stormwater ow from a single

inlet pipe, multiple inlet pipes, and/or from the surface through an inlet grate. Stormceptor EF can also

serve as a junction structure, accommodate a 90-degree inlet to outlet bend angle, and be modied to

ensure performance in submerged conditions. With its scour prevention technology and internal bypass,

Stormceptor EF can be installed online, eliminating the need for costly additional bypass structures.

OPERATION

• Stormwater enters the Stormceptor upper chamber through the inlet pipe(s) or a surface inlet grate.

A specially designed insert reduces the inuent velocity by creating a pond upstream of the insert’s

weir. Sediment particles immediately begin to settle. Swirling ow sweeps water, sediment, and

oatables across the sloped surface of the insert to the inlet opening of the drop pipe, where a

strong vortex draws water, sediment, oil, and debris down the drop pipe cone.

• Inuent exits the cone into the drop pipe duct. The duct has two large rectangular outlet openings

as well as perforations in the backside and oor of the duct. Inuent is diffused through these

various opening in multiple directions and at low velocity into the lower chamber.

• Free oils and oatables rise up and are trapped beneath the insert, while sediment settles to the

sump. Pollutants are retained for later removal during maintenance cleaning.

• Treated efuent enters the outlet riser, moves upward, and discharges to the top side of the insert

downstream of the weir, where it ows out the outlet pipe.

• During intense storm events with very high inuent ow rates, the pond height on the upstream side

of the weir may exceed the height of the weir, and the excess ow passes over the top of the weir

to the downstream side of the insert, and exits through the outlet pipe. This internal bypass feature

allows for online installation, avoiding the cost of additional bypass structures. During bypass,

the pond separates sediment from all incoming ows, while full treatment in the lower chamber

continues at the maximum ow rate.

• Stormceptor EF’s patent-pending enhanced ow and scour prevention technology ensures

pollutants are captured and retained, allowing excess ows to bypass during infrequent, high

intensity storms.

4Stormceptor ® EF Owner's Manual

Figure 2

WEIR

INLET PIPE

DROP PIPE

DUCT

OUTLET

PIPE

OUTLET RISER

OUTLET RISER VANE

INSERT

Figure 1

INLET PIPE

INSERT

DROP PIPE

ACCESS COVER

WEIR

OUTLET

PIPE

OIL INSPECTION

PIPE

5

Stormceptor ® EF Owner's Manual

• Insert – separates vessel into upper and lower chambers, and provides double-wall containment of

hydrocarbons

• Weir – creates stormwater ponding and driving head on top side of insert

• Drop pipe – conveys stormwater and pollutants into the lower chamber

• Outlet riser – conveys treated stormwater from the lower chamber to the outlet pipe, and provides

primary inspection and maintenance access into the lower chamber

• Outlet riser vane – prevents formation of a vortex in the outlet riser during high ow rate conditions

• Oil inspection pipe – primary access for measuring oil depth, and oil removal

IDENTIFICATION

Each Stormceptor EF/EFO unit is easily identiable by the

trade name Stormceptor ®embossed on the access cover at

grade as shown in Figure 3. The tradename Stormceptor ®

is also embossed on the top of the insert upstream of the weir

as shown in Figure 3.

The unit serial number is identied on the top of the insert upstream of the weir as shown in Figure 4.

Figure 3

Figure 4

SERIAL

NUMBER TAG

6Stormceptor ® EF Owner's Manual

MODEL DETAILS

TABLE 1. METRIC DIMENSIONS AND CAPACITIES

Stormceptor

Model

Inside

Diameter

Minimum

Surface to

Outlet Invert

Depth

Depth

Below

Outlet

Pipe Invert

Wet

Volume

Sediment

Capacity1

Hydrocarbon

Storage

Capacity2

Maximum

Flow Rate

into Lower

Chamber3

Peak

Conveyance

Flow Rate4

(m) (mm) (mm) (L) (m3) (L) (L/s) (L/s)

EF4 / EFO4 1.22 915 1524 1780 1.19 265 22.1 / 10.4 425

EF6 / EFO6 1.83 915 1930 5070 3.47 610 49.6 / 23.4 990

EF8 / EFO8 2.44 1219 2591 12090 8.78 1070 88.3 / 41.6 1700

EF10 / EFO10 3.05 1219 3251 23700 17.79 1670 138 / 65 2830

EF12 / EFO12 3.66 1524 3886 40800 31.22 2475 198.7 / 93.7 2830

TABLE 2. U.S. DIMENSIONS AND CAPACITIES

Stormceptor

Model

Inside

Diameter

Minimum

Surface to

Outlet Invert

Depth

Depth

Below

Outlet

Pipe Invert

Wet

Volume

Sediment

Capacity1

Hydrocarbon

Storage

Capacity2

Maximum

Flow Rate

into Lower

Chamber3

Peak

Conveyance

Flow Rate4

(ft) (in) (in) (gal) (ft3) (gal) (cfs) (cfs)

EF4 / EFO4 4 36 60 471 42 70 0.78 / 0.37 15

EF6 / EFO6 6 36 76 1339 123 160 1.75 / 0.83 35

EF8 / EFO8 8 48 102 3194 310 280 3.12 / 1.47 60

EF10 / EFO10 10 48 128 6261 628 440 4.87 / 2.30 100

EF12 / EFO12 12 60 153 10779 1103 655 7.02 / 3.31 100

1. Sediment Capacity is measured from the oor to the bottom of the drop pipe cone. Sediment Capacity can be increased to accommodate

specic site designs and pollutant loads. Contact your local representative for assistance.

2. Hydrocarbon Storage Capacity is measured from the bottom of the outlet riser to the underside of the insert. Hydrocarbon Storage Capacity

can be increased to accommodate specic site designs and pollutant loads. Contact your local representative for assistance.

3. EF Maximum Flow Rate into Lower Chamber is based on a maximum surface loading rate (SLR) into the lower chamber of 1135 L/min/m2

(27.9 gpm/ft2). EFO Maximum Flow Rate into Lower Chamber is based on a maximum surface loading rate (SLR) into the lower chamber of

535 L/min/m2(13.1 gpm/ft2).

4. Peak Conveyance Flow Rate is limited by a maximum velocity of 1. m/s (5 fps).

7

Stormceptor ® EF Owner's Manual

INSPECTION AND MAINTENANCE

It is important to perform regular inspection and maintenance. Regular inspection and maintenance

ensures maximum operation efciency, keeps maintenance costs low, and provides continued protection of

natural waterways.

Quick Reference

• Typical inspection and maintenance is performed from grade

• Remove manhole cover(s) or inlet grate to access insert and lower chamber

NOTE: If an inlet grate is present, EF4/EFO4 requires the removal of a ow deector

beneath inlet grate

• Use Sludge Judge®or similar sediment probe to check sediment depth through the outlet riser

• Oil dipstick can be inserted through the oil inspection pipe

• Visually inspect the insert for debris, remove debris if present

• Visually inspect the drop pipe opening for blockage, remove blockage if present

• Visually inspect insert and weir for damage, schedule repair if needed

• Insert vacuum hose and jetting wand through the outlet riser and extract sediment and oatables

• Replace ow deector (EF4/EFO4), inlet grate, and cover(s)

When is inspection needed?

• Post-construction inspection is required prior to putting the Stormceptor into service.

• Routine inspections are recommended during the rst year of operation to accurately assess

pollutant accumulation.

• Inspection frequency in subsequent years is based on the maintenance plan developed in the rst

year.

• Inspections should also be performed immediately after oil, fuel, or other chemical spills.

What equipment is typically required for inspection?

• Manhole access cover lifting tool

• Oil dipstick / Sediment probe with ball valve (typically ¾-inch to 1-inch diameter)

• Flashlight

• Camera

• Data log / Inspection Report

• Safety cones and caution tape

• Hard hat, safety shoes, safety glasses, and chemical-resistant gloves

8Stormceptor ® EF Owner's Manual

When is maintenance cleaning needed?

• If the post-construction inspection indicates presence of construction sediment of a depth

greater than a few inches, maintenance is recommended at that time. For optimum performance

and normal operation the unit should be cleaned out once the sediment depth reaches the

recommended maintenance sediment depth, see Table 3.

• Maintain immediately after an oil, fuel, or other chemical spill.

TABLE 3

RECOMMENDED SEDIMENT DEPTHS FOR MAINTENANCE SERVICE*

MODEL Sediment Depth

in mm

EF4 / EFO4 8 203

EF6 / EFO6 12 305

EF8 / EFO8 24 610

EF10 / EFO10 24 610

EF12 / EFO12 24 610

* Based on a minimum distance of 40 inches (1,016 mm) from bottom of outlet riser to top of sediment bed

The frequency of inspection and maintenance may need to be adjusted based on site conditions to ensure

the unit is operating and performing as intended. Maintenance costs will vary based on the size of the unit,

site conditions, local requirements, disposal costs, and transportation distance.

What equipment is typically required for maintenance?

• Vacuum truck equipped with water hose and jet nozzle

• Small pump and tubing for oil removal

• Manhole access cover lifting tool

• Oil dipstick / Sediment probe with ball valve (typically ¾-inch to 1-inch diameter)

• Flashlight

• Camera

• Data log / Inspection Report

• Safety cones

• Hard hats, safety shoes, safety glasses, chemical-resistant gloves, and hearing protection for

service providers

• Gas analyzer, respiratory gear, and safety harness for specially trained personnel if conned space

entry is required (adhere to all OSHA / CCOSH standards)

9

Stormceptor ® EF Owner's Manual

What conditions can compromise Stormceptor performance?

• Presence of construction sediment and debris in the unit prior to activation

• Excessive sediment depth beyond the recommended maintenance depth

• Oil spill in excess of the oil storage capacity

• Clogging or restriction of the drop pipe inlet opening with debris

• Downstream blockage that results in a backwater condition

MAINTENANCE PROCEDURES

• Maintenance should be conducted during dry weather conditions when no ow is entering the unit.

• Stormceptor is maintained from grade through a standard surface manhole access cover or inlet

grate.

• In the case of submerged or tailwater conditions, extra measures are likely required, such as

plugging the inlet and outlet pipes prior to conducting maintenance.

• Inspection and maintenance of upstream catch basins and other stormwater conveyance structures

is also recommended to extend the time between future maintenance cycles.

• Sediment depth inspections are performed through the Outlet Riser and oil presence can be

determined through the Oil Inspection Pipe (see Figures 6 and 7).

• Oil presence and sediment depth are determined by inserting a Sludge Judge®or measuring stick

to quantify the pollutant depths.

• Visually inspect the insert, weir, and drop pipe inlet opening to ensure there is no damage or

blockage.

Figure 5 Figure 6

OUTLET

RISER

OIL

INSPECTION

PIPE

SLUDGE

JUDGE®

ACCESS

COVER

10 Stormceptor ® EF Owner's Manual

OUTLET

RISER VANE

• When maintenance is required, a standard vacuum truck is used to remove the pollutants from the

lower chamber of the unit through the Outlet Riser (see Figure 7).

Figure 7

Figure 8

Figure 9

• The Outlet Riser Vane is durable and exible and designed to allow maintenance activities with

minimal, if any, interference (see Figure 8).

Removable Flow Detector

REMOVABLE FLOW DEFLECTOR

• Grated inlets for the Stormceptor EF4/EFO4 model requires a removable ow deector staged

underneath a 24-inch x 24-inch (600 mm x 600 mm) square inlet grate to direct ow towards the

inlet side of the insert, and avoid ow and pollutants from entering the outlet side of the insert from

grade (See Figure 9). The EF6/EFO6 and larger models do not require the ow deector.

ANCHOR BOLT

ANCHOR

HANDLE

11

Stormceptor ® EF Owner's Manual

HYDROCARBON SPILLS

Stormceptor is often installed on high pollutant load hotspot sites with vehicular trafc where hydrocarbon

spill potential exists. Should a spill occur, or presence of oil be identied within a Stormceptor EF/EFO, the

unit should be cleaned immediately by a licensed liquid waste hauler.

Disposal

Maintenance providers are to follow all federal, state/ provincial, and local requirements for disposal of

material.

Oil Sheens

When oil is present in stormwater runoff, a sheen may be noticeable at the Stormceptor outlet. An oil

rainbow or sheen can be noticeable at very low oil concentrations (< 10 mg/L). Despite the appearance of

a sheen, Stormceptor EF/EFO may still be functioning as intended.

Oil Level Alarm

To mitigate spill liability with 24/7 detection, an electronic Oil Level Alarm monitoring system can be

employed to trigger a visual and audible alarm when a pre-set level of oil is captured within the lower

chamber or when an oil spill occurs. The oil level alarm is available as an optional feature to include with

Stormceptor EF/EFO as shown in Figure 10.

For additional details about the Oil Level Alarm, please visit

www.imbriumsystems.com/stormwater-treatment-solutions/stormceptor-systems.

REPLACEMENT PARTS

Stormceptor has no moving parts. Therefore, inspection and maintenance activities are generally

focused on pollutant removal. Since there are no moving parts during operation in a Stormceptor, broken,

damaged, or worn parts are not typically encountered. However, if replacement parts are necessary, they

may be purchased by contacting your local Stormceptor representative.

Figure 10

OIL ALARM PROBE

INSTALLED ON

DOWNSTREAM SIDE

OF WEIR

Optional Oil Alarm

12 Stormceptor ® EF Owner's Manual STC EF_OM_9/17

STORMCEPTOR INSPECTION AND MAINTENANCE LOG

Stormceptor Model No: _________________________________________________________________

Serial Number: _______________________________________________________________________

Installation Date: ______________________________________________________________________

Location Description of Unit: _____________________________________________________________

Recommended Sediment Maintenance Depth: ______________________________________________

DATE SEDIMENT

DEPTH

OIL DEPTH

(inches or mm)

SERVICE

REQUIRED

(Y/N)

MAINTENANCE

PERFORMED

MAINTENANCE

PROVIDER COMMENTS

Other Comments: _____________________________________________________________________

CONTACT INFORMATION

Questions regarding Stormceptor EF/EFO can be addressed by contacting your local

Stormceptor representative.

Imbrium Systems Inc.

1-416-960-9900 / 1-800-565-4801 / 888-279-8826

www.imbriumsystems.com

www.stormceptor.com

Table of contents

Popular Water Filtration System manuals by other brands

Strix

Strix Aqua Optima Liscia Instructions for use

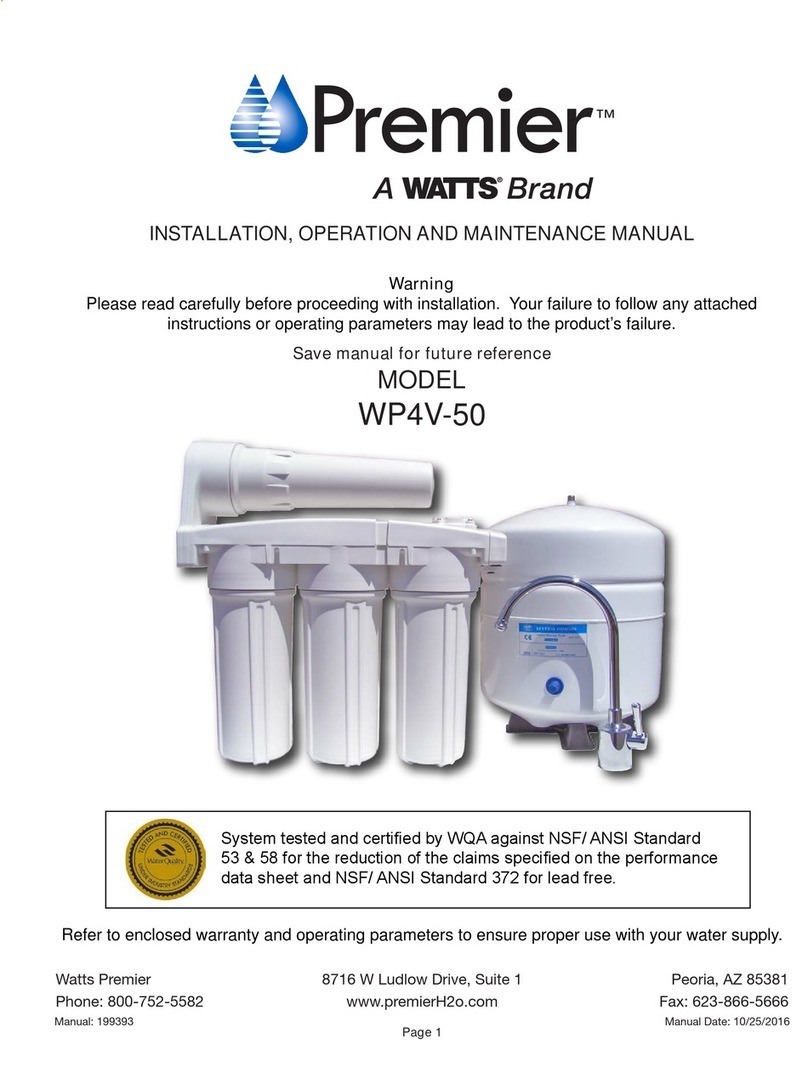

Watts

Watts Premier WP4V-50 Installation, operation and maintenance manual

Pentair

Pentair FRESHPOINT GRO-575M Installation and operation manual

EXFO

EXFO XTM-50 Series user guide

Eureka Forbes

Eureka Forbes Aquaguard select AWS C2500 DX user manual

Graco

Graco 213-062 instructions