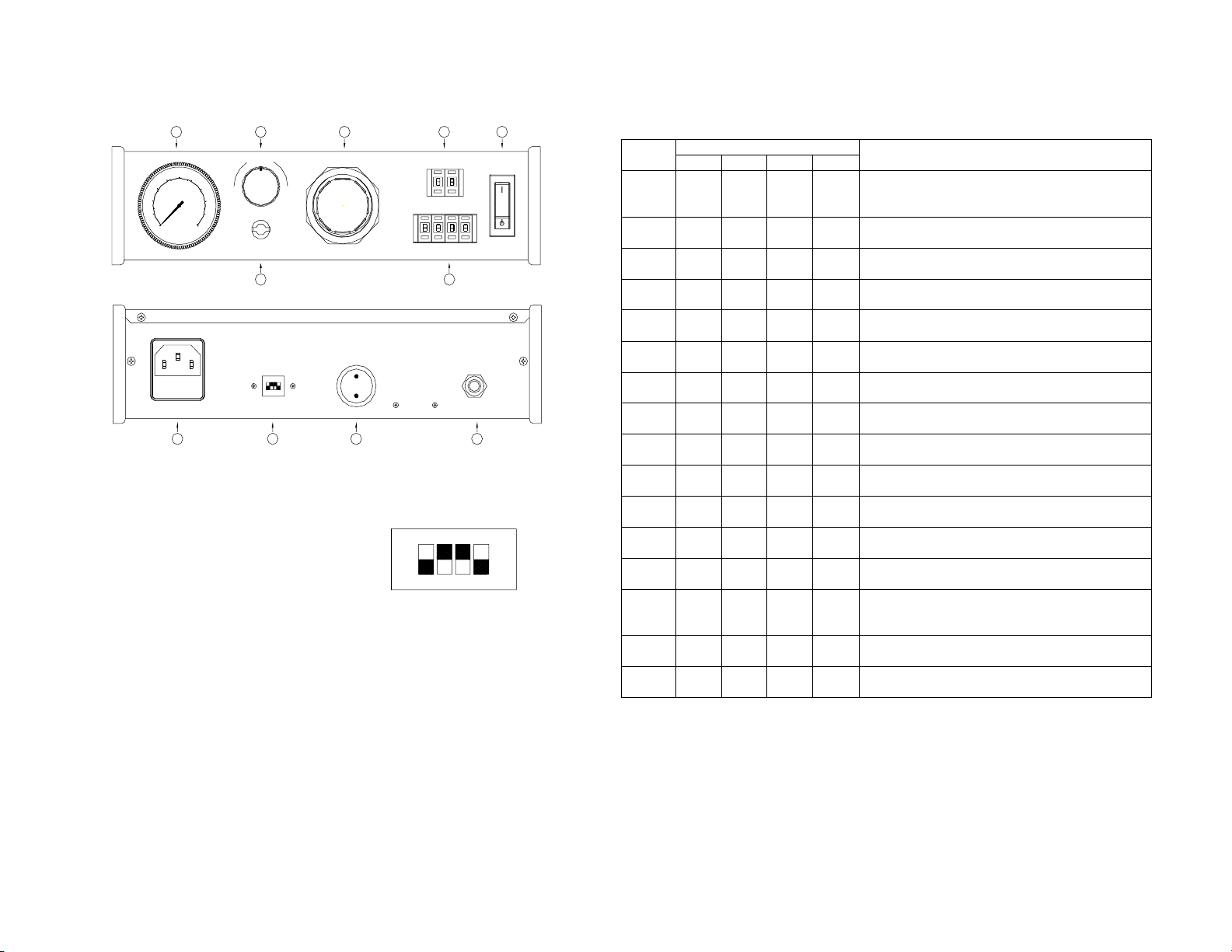

(2).Diagram of front and rear panels

0

10

2

0

30

40

50

60

70

80

90

100

0

1

2

3 4

5

6

7

VACUUM

+-

AI R PRESSUREINTERVAL

DISPENSINGTI ME

ON

OFF

FOOTSWIRTCH

SET UP

FUSE 0. 25

100 PSI MAX

0.7 MPa MAX

AIRIN

12345

67

10 9811

(3)Adjustment of dispensing time and interval

time

(a). Adjustment of dispensing time and interval time.

The dispensing time control button is located on the front panel of the unit.

The dispensing time can be set directly. Press the “+”button, and the

corresponding digit will increase by one. Similarly, press the “- ”button,

the corresponding digit will decrease by one. There are four digits in the

display, with a range from 0.01 second to 99.99 seconds, and the resolution

is 0.01 second.

(b). Interval Time Setup

The interval time control button is located on the front panel of the unit.

The interval time can be set directly. Press the “+”button will increase

the interval by one. Similarly, press the “- ”button will decrease the

interval by one. There are two digits in the display, with a range from 0.1

second to 9.9 seconds, and the resolution is 0.1 second.

Mode Switch Status

Item

No. S1 S2 S3 S4 Function

1 OFF OFF OFF OFF

With pedal switch pressed, dispense

continuously, otherwise it will

stop dispensing.

2 ON OFF OFF OFF Be triggered once, dispense at controlled time

once.

3 OFF ON OFF OFF

Be triggered once, dispense at controlled time

twice.

4 ON ON OFF OFF

Be triggered once, dispense at controlled time

three times.

5 OFF OFF ON OFF

Be triggered once, dispense at controlled time

four times.

6 ON OFF ON OFF

Be triggered once, dispense at controlled time

five times.

7 OFF ON ON OFF

Be triggered once, dispense at controlled time six

times.

8 ON ON ON OFF

Be triggered once, dispense at controlled time

seven times.

9 OFF OFF OFF ON Be triggered once, dispense at controlled time

eight times.

10 ON OFF OFF ON Be triggered once, dispense at controlled time

nine times.

11 OFF ON OFF ON Be triggered once, dispense at controlled time ten

times.

12 ON ON OFF ON Be triggered once, dispense at controlled time

eleven times.

13 OFF OFF ON ON Be triggered once, dispense at controlled time

twelve times.

14 ON OFF ON ON

Be triggered once, dispense at controlled time

continually, the next trigger will stop

dispensing.

15 OFF ON ON ON With pedal switch pressed, dispense at controlled

time continually, or it will stop dispensing.

16 ON ON ON ON Dispense at controlled time continually and

automatically.

Note: Dispensing at controlled time means dispensing according to set dispensing time

and interval time.

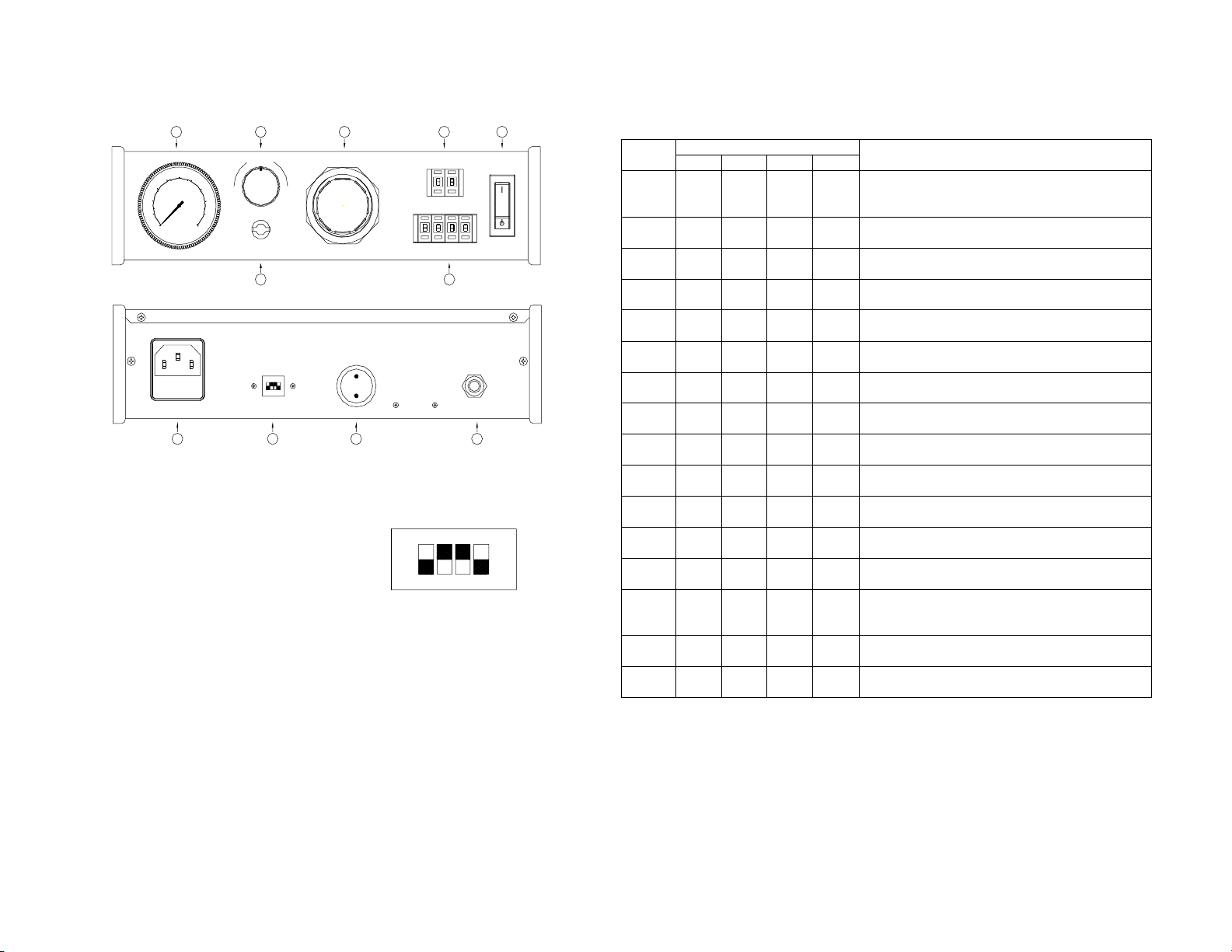

Mode switch on the rear panel of the unit

can be adjusted according to th

following table to suit different needs.

ON

12 43