www.madur.com User manual maMoS

Index

1. Introduction.......................................................................................................................................................................................................................................................... 4

2. Construction......................................................................................................................................................................................................................................................... 5

2.1. Standard equipment.....................................................................................................................................................................................................................................

2.1.1. Analyser module.................................................................................................................................................................................................................................. 6

2.1.2. Panel wit gas and electric connectors............................................................................................................................................................................................. 6

2.1.3. Display.................................................................................................................................................................................................................................................. 8

2.1.4. Work knob............................................................................................................................................................................................................................................. 9

2.1.5. SMPS – switc ed mode power supply............................................................................................................................................................................................. 10

2.1.6. MD2 gas dryer..................................................................................................................................................................................................................................... 11

2.1.7. MD3 gas dryer..................................................................................................................................................................................................................................... 12

2.1.8. Nafion gas dryer................................................................................................................................................................................................................................. 13

2.1.9. Dual-mode gas port............................................................................................................................................................................................................................ 13

2.2. Inside mamos analyser.............................................................................................................................................................................................................................. 1

2.2.1. Gas sensors........................................................................................................................................................................................................................................ 16

2.2.2. Gas pump............................................................................................................................................................................................................................................ 16

2.2.3. Ventilation valve................................................................................................................................................................................................................................. 17

2.2.4. Condensate pump.............................................................................................................................................................................................................................. 17

2.2.5. Electric terminals............................................................................................................................................................................................................................... 18

2.2.6. Communication interfaces................................................................................................................................................................................................................ 19

2.3. Optional equipment.................................................................................................................................................................................................................................... 19

2.3.1. Stationary gas probe.......................................................................................................................................................................................................................... 20

2.3.2. Heated line.......................................................................................................................................................................................................................................... 21

2.3.3. Heated filter........................................................................................................................................................................................................................................ 22

2.3.4. IP55 cabinet........................................................................................................................................................................................................................................ 23

2.3.5. Data-logger......................................................................................................................................................................................................................................... 23

2.3.5.1. Control button.............................................................................................................................................................................................................................. 24

2.3.5.2. Format SD card............................................................................................................................................................................................................................ 24

2.3.5.3. Status LED.................................................................................................................................................................................................................................... 2

2.4. Differential pressure sensor...................................................................................................................................................................................................................... 26

3. Possible working configurations...................................................................................................................................................................................................................... 27

3.1. Compact configurations............................................................................................................................................................................................................................ 27

3.2. Split configuration...................................................................................................................................................................................................................................... 27

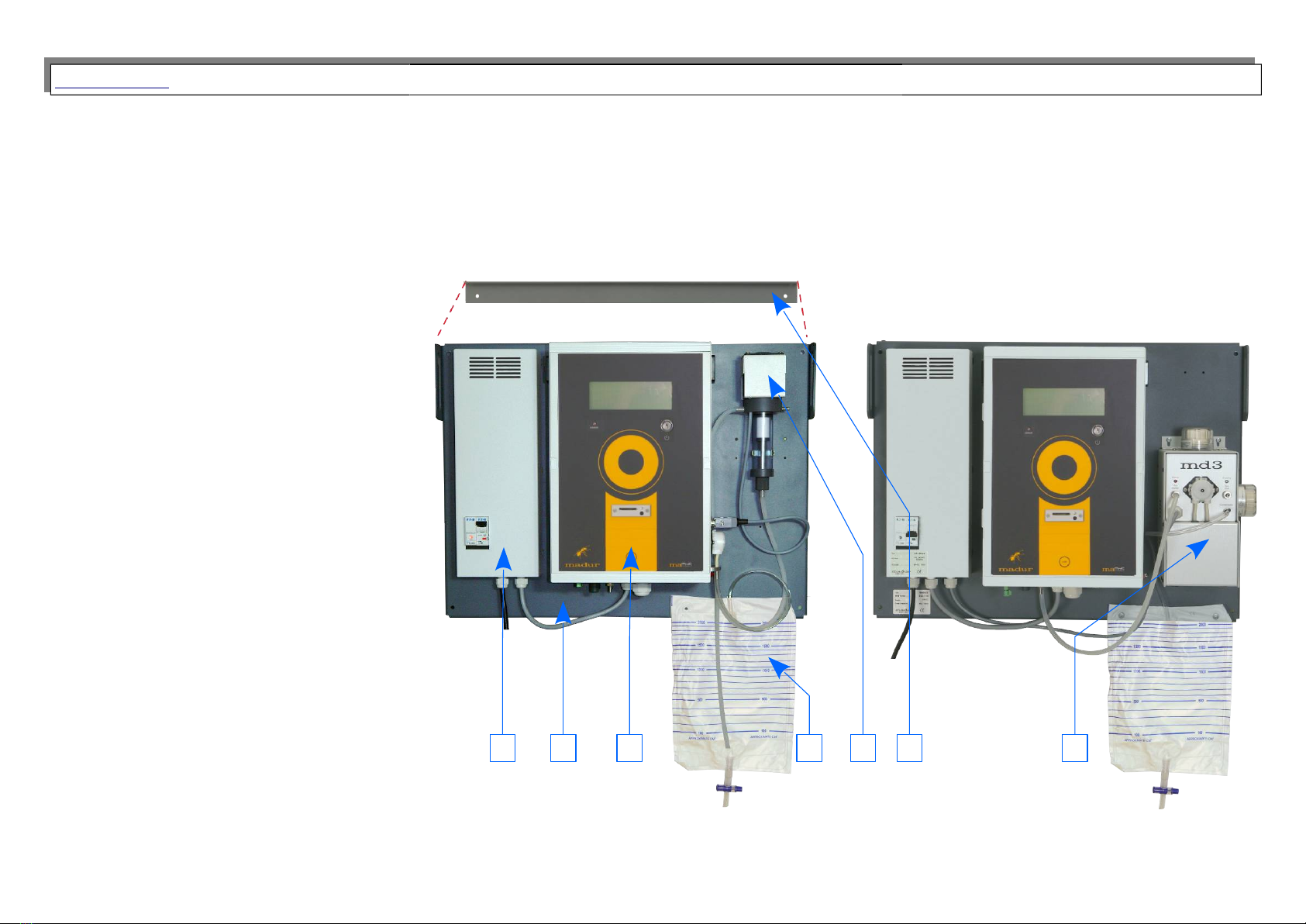

3.3. Twin-split configuration............................................................................................................................................................................................................................. 28

3.3.1. Twin-split configuration wit one remote dryer.............................................................................................................................................................................. 28

2