Sensonic 4000 CONTENTS

1 CONTENTS

1 CONTENTS............................................................................................................................................

2 INTRODUCTION...................................................................................................................................

2.1 USE OF THIS OPERATING MANUAL............................................................................................

2.2 SYMBOLS USED..............................................................................................................................

3 MAINTENANCE....................................................................................................................................

3.1 Gas sensors.......................................................................................................................................

3.2 Gas sys em........................................................................................................................................

3.3 Ba ery..............................................................................................................................................

3.4 Service in ervals................................................................................................................................

3.5 Errors during opera ion....................................................................................................................

3.6 Swi ching off af er use.......................................................................................................................

4 GENERAL INFORMATION...................................................................................................................

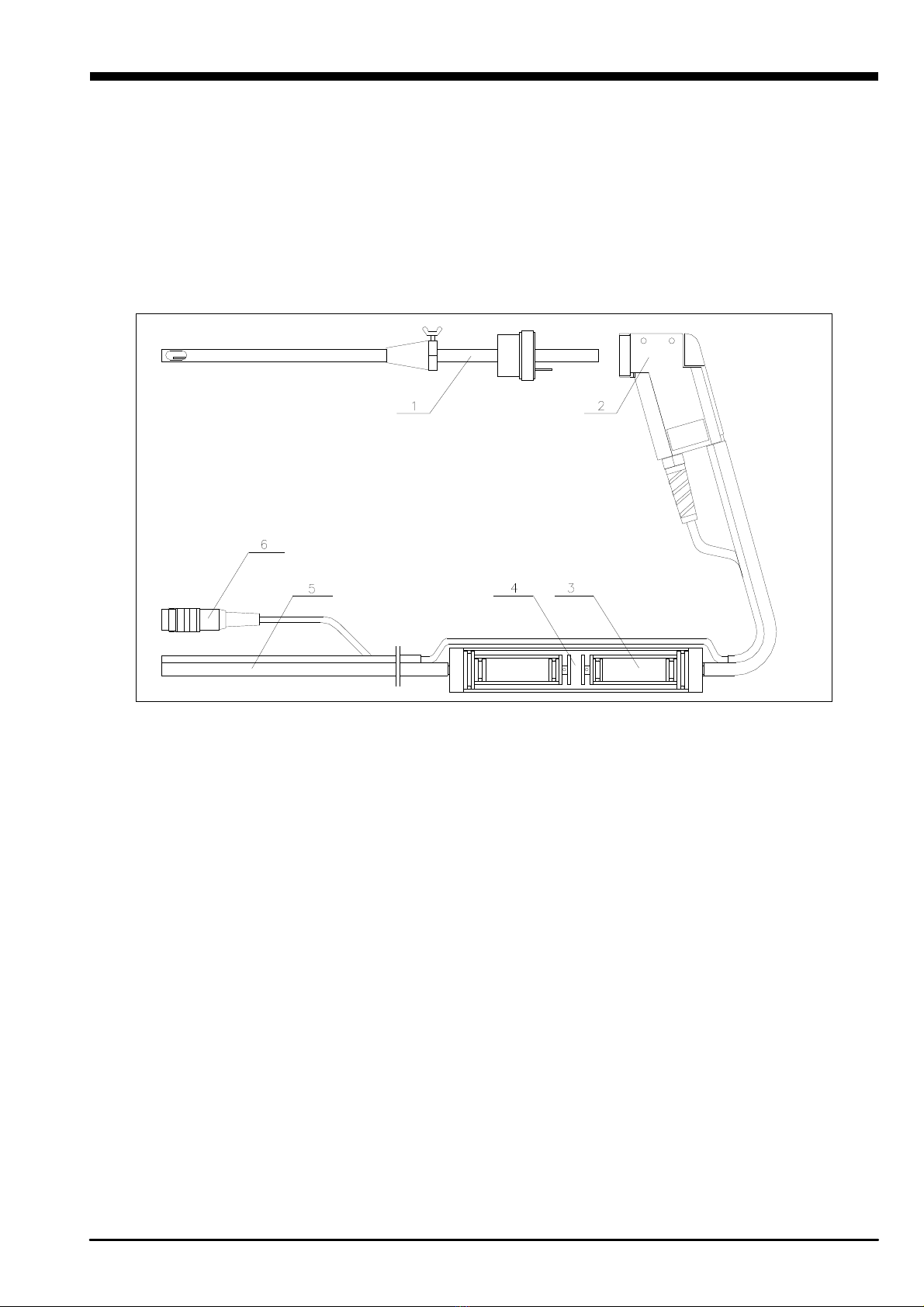

5 CONSTRUCTION..................................................................................................................................

5.1 Elemen s of gas circui ......................................................................................................................

5.1.1 Gas probe wi h in-line fil er.........................................................................................................

5.1.2 Gas pump.....................................................................................................................................

5.1.3 Gas chamber................................................................................................................................

5.2 Measuremen sys em.........................................................................................................................

5.2.1 Gas sensors..................................................................................................................................

5.2.2 Ambien air empera ure sensor...................................................................................................

5.2.3 Flue gas empera ure sensor........................................................................................................

5.2.4 Gas chamber empera ure sensor................................................................................................

5.2.5 Differen ial pressure sensor.......................................................................................................

5.2.6 Analogue inpu s.........................................................................................................................

5.3 Da a inpu /ou pu sys ems...............................................................................................................

5.3.1 Keyboard...................................................................................................................................

5.3.2 Display.......................................................................................................................................

5.3.3 Prin er........................................................................................................................................

5.3.4 In erface RS 232C......................................................................................................................

5.4 Power supply..................................................................................................................................

6 OPERATION........................................................................................................................................

6.1 USE OF THE KEYBOARD.............................................................................................................

6.1.1 Descrip ion of he keys...............................................................................................................

6.1.2 Selec ing Menu Op ions.............................................................................................................

6.1.3 En ering Numbers......................................................................................................................

6.1.4 Edi ing Tex ................................................................................................................................

6.2 Basic opera ing ins ruc ions...........................................................................................................

6.2.1 Se ing-up he analyser..............................................................................................................

6.2.2 Swi ching on...............................................................................................................................

6.2.3 Swi ching off / S andby..............................................................................................................

6.2.4 Ini ial Calibra ion......................................................................................................................

6.2.5 Measuremen Parame ers..........................................................................................................

6.2.5.1 Fuel 19

6.2.5.2 Average Time.....................................................................................................................

6.2.5.3 Reference Oxygen parame er.............................................................................................

6.2.5.4 Boiler Parame er................................................................................................................

6.2.5.5 Con en of NO in NOx........................................................................................................

6.3 Displaying he measuremen resul s...............................................................................................

6.3.1 Curren Values...........................................................................................................................

6.3.2 Averaged Values.................................................................................................................

6.3.3 The Averaging Process..............................................................................................................

6.4 Pressure/Draf Measuremen s........................................................................................................

6.5 Soo (smoke) Con en s Measuremen ..............................................................................................

6.6 Graphic...........................................................................................................................................

40PLUS_E.DOC/06.97