1-800-MAGLINE (624-5463)

LiftPlus®

2

Table of Contents

LiftPlus Toolkit........................................................................................................................................3

Safety Instructions.................................................................................................................................4

Removing Covers..................................................................................................................................5

Disconnecting/Connecting Battery ........................................................................................................6

Lift Screw Girdle and Upper Belt ...........................................................................................................7

Replacing Lower Belt.............................................................................................................................7

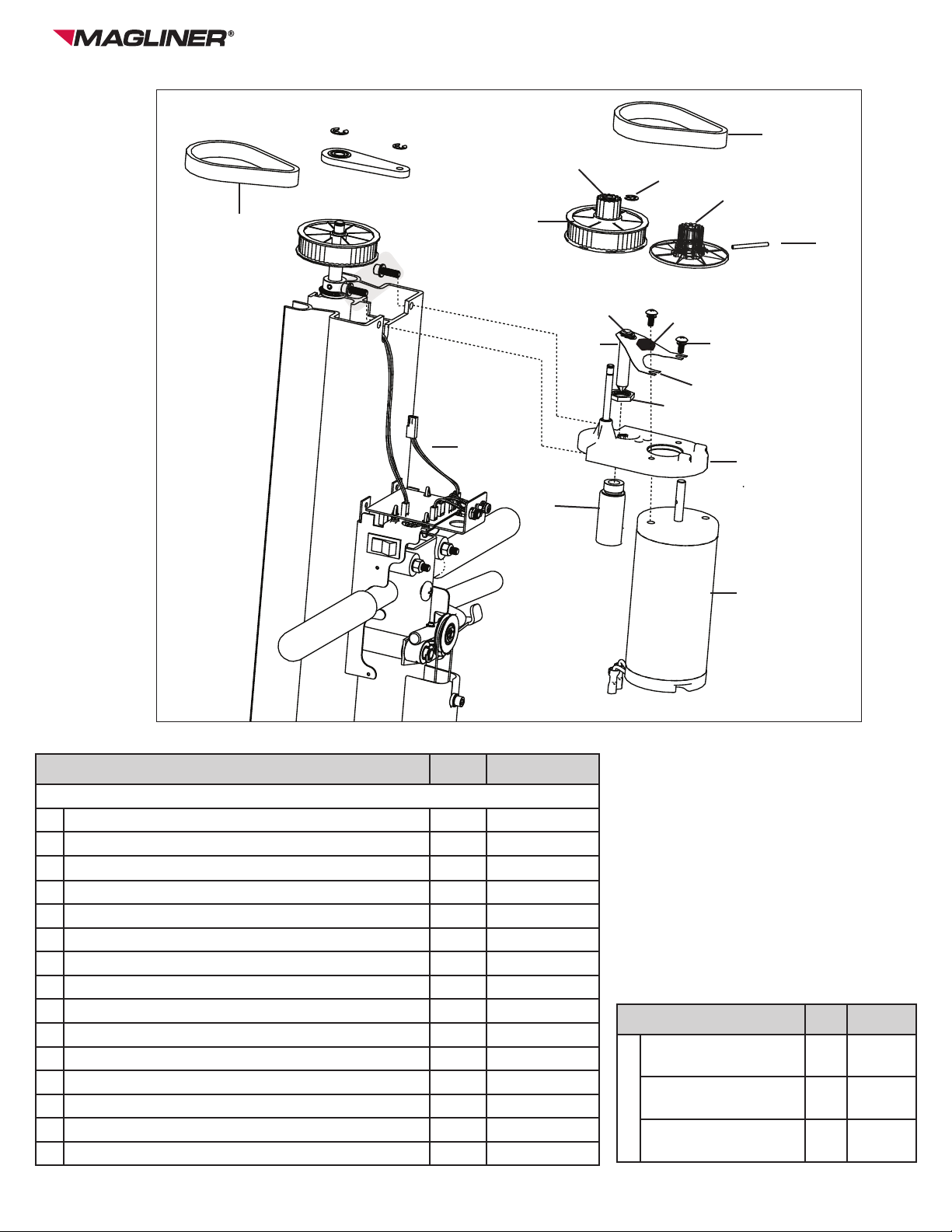

Motor Assembly.....................................................................................................................................8

Pulleys 1, 2-3.......................................................................................................................................10

Motor and Solenoid Body....................................................................................................................10

Motor Brake Pad .................................................................................................................................11

Lower Lift Screw Collar and Assembly................................................................................................13

Pulley 4................................................................................................................................................13

Lift Screw Thrust Bearing ....................................................................................................................14

Lift Screw Guide ..................................................................................................................................14

Trolley Assembly .................................................................................................................................16

Rear Rollers.........................................................................................................................................16

Front Rollers....................................................................................................................................... 17

Caster Assembly................................................................................................................................. 17

Disengaging/Engaging Brake Cable Ends ..........................................................................................19

Brake Cable Assembly ........................................................................................................................19

Brake Caliper Assembly ......................................................................................................................19

Adjusting the Brakes, Caliper ........................................................................................................ 20-21

Replacing Battery ................................................................................................................................22

Battery Box..........................................................................................................................................22

Circuit Breaker.....................................................................................................................................22

Lower Limit Switch...............................................................................................................................24

Upper Limit Switch...............................................................................................................................25

Power Switch; Up/Down Switch ..........................................................................................................26

Charging Light; Overload Light............................................................................................................26

Charging Input; Remote Control Input.................................................................................................27

Control Board Diagram.................................................................................................................. 28-29

Maintenance........................................................................................................................................30

Troubleshooting Guide ........................................................................................................................31

Advanced Troubleshooting Guide ................................................................................................. 32-34

Replacement Parts List ................................................................................................................. 54-56

Inspection / Maintenance Checklist................................................................................................ 57-63