5. OPERATION AND FOODSTUFF ALLOCATION

It is important to note that this equipment is not designed to increase the temperature of products,

but only to maintain the temperature at which they are stored

To optimize the operation of the equipment and keep the food in good condition, use only the

add-ons and accessories supplied with the display case.

the equipment is equipped with glass shutters, they need to be opened and closed carefully.

Do not use the roof of the display cabinet to store packing, spare parts and other materials.

5.1 PREPARING THE DISPLAY CASE FOR USE

Before using the display case, it is required to wash (clean) its inner and outer surfaces with a

detergent, see section 8 for recommendations on cleaning the display case.

Before cleaning, make sure that the display case is disconnected (the main switch of the display

case on the control panel is turned off, the switches "OPERATION" and "LIGHTING" are fixed in

the "OFF" position).

Avoid using abrasives and solvents that can damage the surface of the display case. Avoid

getting water and detergents on the parts of the display case that are under electric voltage.

It is recommended to wash the cleaned surfaces with clean water and wipe dry.

Lifting the front window of the showcase, lift it without jerks and with two hands, holding on to the

middle part until it locks in the upper position. Close the display case in the same way until the

front window is fixed in the lower position.

ATTENTION: IT IS UNACCEPTABLE TO LIFT UP (LOWER DOWN) THE FRONT GLASS

HOLDING ITS EDGE. THE EXCESSIVE EFFORT AND SKEWING OF THE GLASS MAY

OVERLOAD THE EDGE OF THE GLASS AND, AS A RESULT, DESTROY IT.

5.2 TURNING ON THE DISPLAY CASE

Turn on the display case only after carrying out all preparatory works fulfilled by qualified

personnel.

To turn on the showcase, do the following:

- apply the power to the display case by turning on the automatic switch on the display case

control panel;

- turn on the toggle switches "OPERATION" and "LIGHTING" located on the control panel.

After a few seconds, the display case will turn on.

After the temperature in the display case reaches the set values, the food staff can be loaded.

To turn off the display case, turn off the toggle switches "OPERATION" and "LIGHTING",

disconnect the case from the power by turning off the automatic switch on the control panel.

ATTENTION: IF A BURNING SMELL APPEARS, THE OPERATION OF THE DISPLAY CASE

SHOULD BE STOPPED IMMEDIATELY, AND QUOLIFIED MAINTENANCE PERSONNEL

SHOULD BE CALLED TO ESTABLISH AND ELIMINATE THE CAUSE OF ITS ABNORMAL

OPERATION.

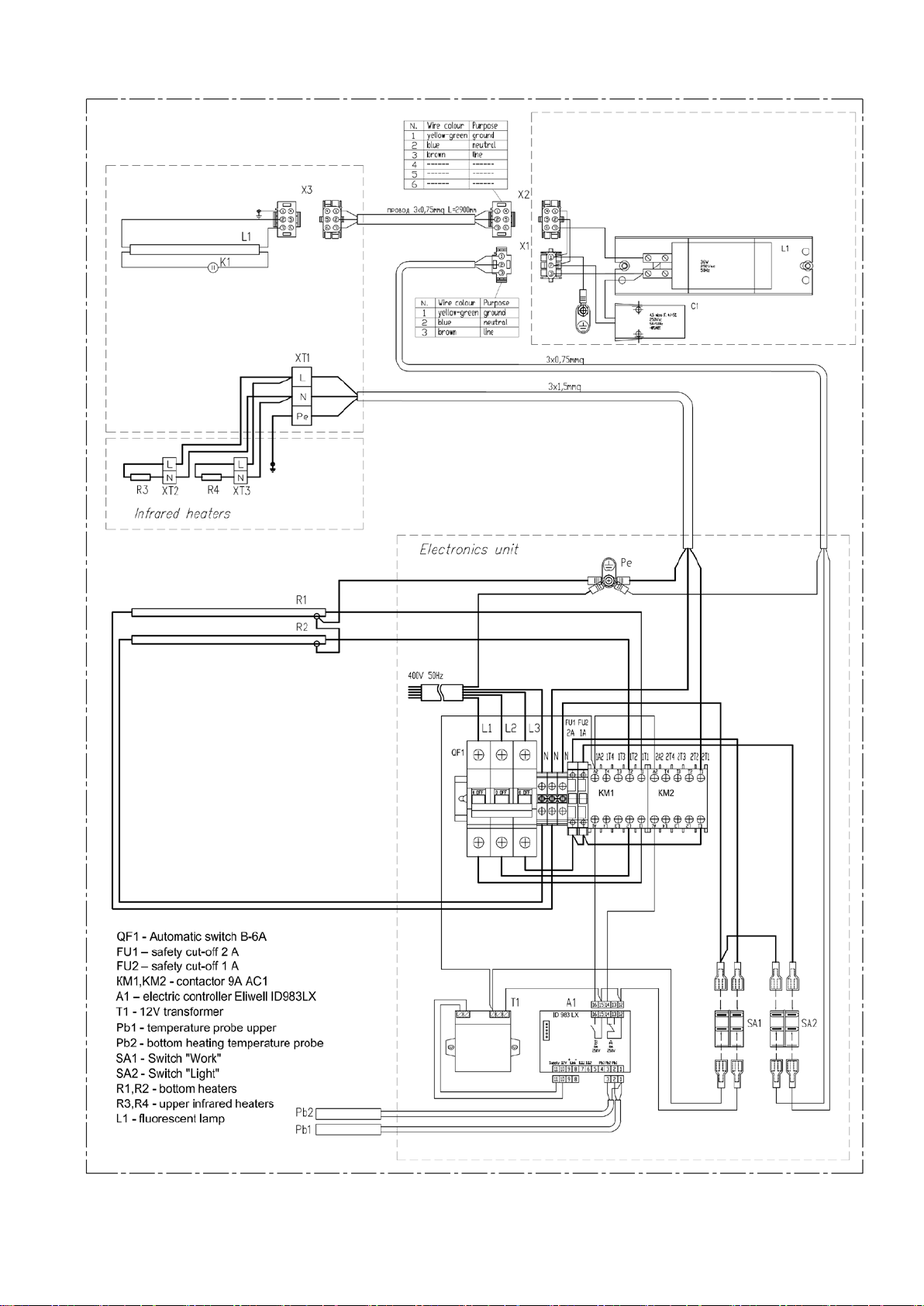

5.3 CONTROL AND ADJUSTMENT OF THE OPERATING TEMPERATURE

If the equipment is not connected to a central monitoring system with an alarm, you should check

the temperature value displayed on the controller screen several times a day, or at regular

intervals, in accordance with local regulations.

The digital display of the electronic controller mounted on the control panel of the electronics unit

and the mechanical thermometer mounted on the front panel of the showcase allow visual control

of the operating temperature.

The electronic controller manages Automatic control and maintaining of the operating

temperature within the specified limits.

The procedure for changing the operating temperature setting is given in Appendix C.

As a reminder, the controller has factory settings and their changes must be carried out by a

qualified specialist.