4. STRUCTURE OF THE DISPLAY CASE

The display case represents a steamer display counter with two-zone controlled heating. The display case

consists of the following functional parts:

- water reservoir with electric heaters;

- upper thermal ceiling with ceramic heaters;

- upper lighting lampshade;

- water filling systems;

- control unit with electronic controller.

4.1 The water reservoir is equipped with:

- filling nozzle installed in the upper part of the reservoir, which is connected to the FILLING valve via an

electromagnetic valve (black color);

- a drain pipe installed in the bottom of the reservoir and connected to the DRAIN valve (red);

- overflow holes located above the level "MAXIMUM LEVEL" fixed by the water level sensor;

- a two-position water level sensor connected to an electronic controller and fixing the "MINIMUM LEVEL"

and "MAXIMUM LEVEL".

- steam temperature sensor installed in the upper part of the bath;

- tubular electric heating elements, the operation of which is controlled by an electronic controller using data

from a steam reservoir, temperature sensor and a water level sensor.

4.2 The upper thermal ceiling is equipped with ceramic Infrared heating elements, the operation of which is

controlled by an electronic controller using an upper volume temperature sensor. The heat lamp is powered

immediately as the display case is turned on.

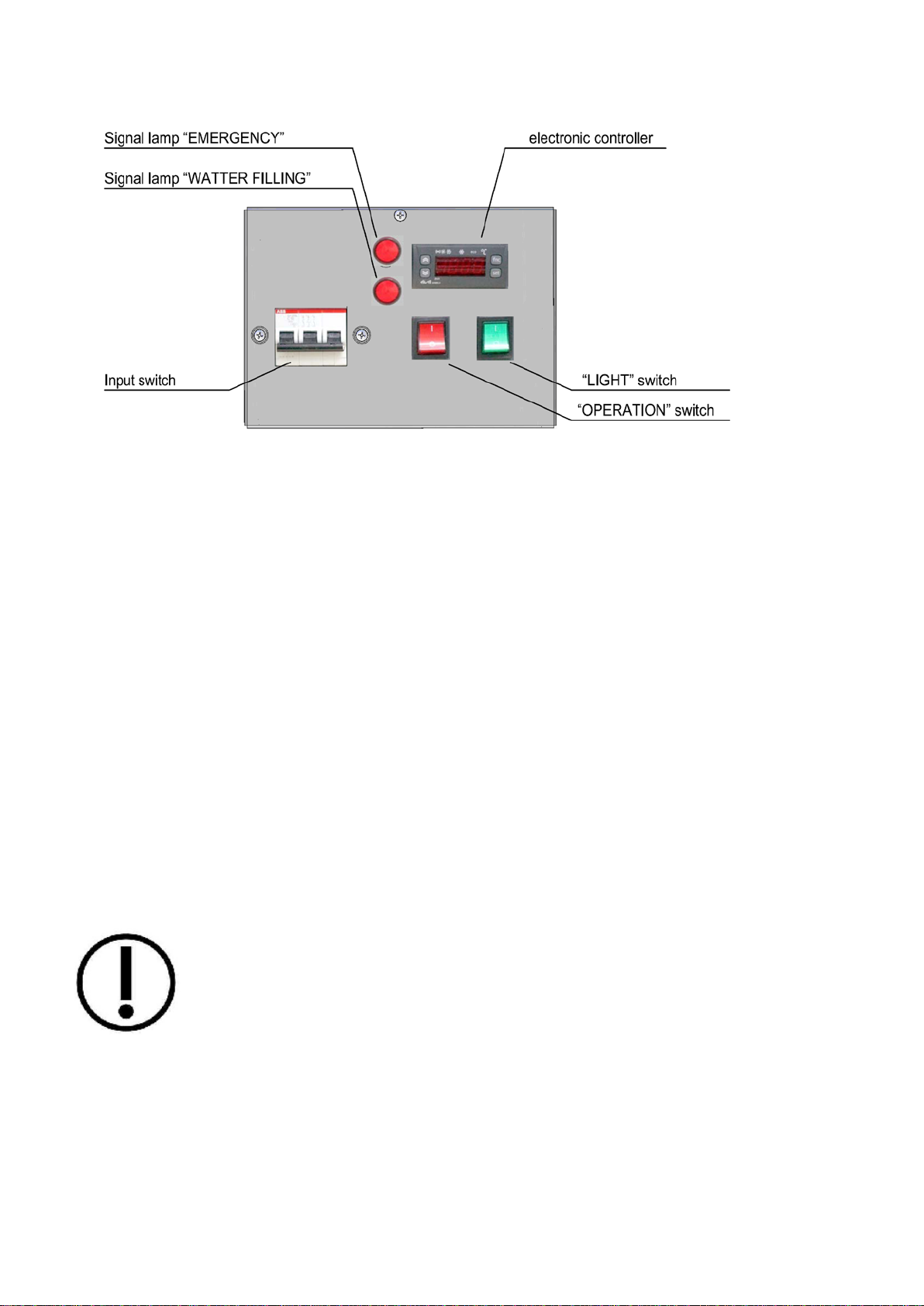

4.3 The interior lighting of the case is carried out by LED lamps located in the upper lamp. The "LIGHTING"

switch is located on the front side of the display case control unit.

4.4 For the supply of cold water, a "FILLING" valve is installed on the case (black color). A "DRAIN" valve (red

color) serves to drain the water from the display case reservoir.

In case of an emergency overflow of the reservoir a drain pipe with a siphon connected to the sewer water

drainage pipeline is installed on the bottom of the display case. It removes the water trapped inside the display

case.

An electromagnetic valve is installed on the water-filling pipe to automatically replenish the water in the

reservoir. The operation of the solenoid valve is controlled by an electronic controller on the signal "MINIMUM

LEVEL" of the water level sensor.

4.5 The case is controlled by the electronic controller Eliwell ID 985 LX, located under the bottom on the seller's

side. It is configured to control heating and perform other functions of the display case.

A list of the main parameters of the controller responsible for the operation of the case is given in Appendix D.

Detailed information on how to program the controller is contained in the User Manual for the controller,

supplied with the showcase.

The electronic controller manages the following functions:

- maintaining the set temperatures in two zones (reservoir, upper space);

- automatic replenishment of water in the display case reservoir;

- alarming and operation in emergency situations.

To control the showcase, the following resources of the ID 985 LX controller are employed:

- to control the heating of the ceramic heating elements of the thermal ceiling (upper space), the resources

of the compressor control channel (compressor channel relay, Pb1 sensor) are used. The heating elements

of the ceiling are connected to the inverse output of the compressor channel;

- to control the heating of the heating elements of the water reservoir, the resources of the fan control

channel (fan channel relay, Pb2 sensor) are used. The heating elements of the water bath are connected to

a relay configured as a fan channel relay;

- the "MINIMUM LEVEL" sensor is connected to the digital input DI_1 (configured as a door relay (light

control));

- the "LEVEL MAXIMUM" sensor is connected to the digital input DI_2 (configured as an external fault);

- the water filling solenoid valve is connected to a relay configured as a "light" relay, in parallel with the

"WATER FILLING" signal lamp;

- the "EMERGENCY" alarm lamp is connected to a relay configured as an "Emergency" relay.

The electrical schematic diagram of the display case is given in Appendix A, B.