MONOTIG 220ip - MONOTIG 220ip AC/DC

EN

www.magmaweld.com

8

USER MANUAL | KULLANIM KILAVUZU

Accordng to artcle 5.2 of IEC 60974-9;

Before nstallng the weldng and cuttng equpment, the person n charge of the operaton and/or the

user must conduct an nspecton of possble electromagnetc nterference n the envronment. Aspects

ndcated below has to be taken nto consderaton;

a)Other supply cables, control cables, sgnal and telephone cables, above and below the weldng

machne and ts equpment,

b)Rado and televson transmtters and recevers,

c) Computer and other control hardware,

d)Crtcal safety equpment, e.g. protecton of ndustral equpment,

e)Medcal apparatus for people n the vcnty, e.g. pacemakers and hearng ads,

f)Equpment used for measurng or calbraton,

g)Immunty of other equpment n the envronment. The user must ensure that the other equpment n

use n the envronment s compatble.Ths may requre addtonal protecton measures.

h)Consderng the tme durng whch the weldng operatons or other actvtes take place durng the

day, the boundares of the nvestgaton area can be expanded accordng to the sze of the buldng,

the structure of the buldng and other actvtes that are beng performed n the buldng.

In addton to the evaluaton of the feld, evaluaton of devce nstallatons may also be necessary for

solvng the nterferng eect.

In case f deemed necessary, on-ste measurements can also be used to confrm the ecency of

mtgaton measures. (Source: IEC 60974-9).

• The applance must be connected to the electrcty supply n the recommended manner by a compe-

tent person. If nterference occurs, addtonal measures may be appled, such as flterng the network.

The supply of the fxed-mounted arc weldng equpment must be made n a metal tube or wth an

equvalent shelded cable.The housng of the power supply must be connected and a good electrcal

contact between these two structures has to be provded.

• The recommended routne mantenance of the applance must be carred out. All covers on the body

of the machne must be closed and/or locked when the devce s n use. Any changes, other than the

standard settngs wthout the wrtten approval of the manufacturer, cannot be modfed on the

applance. Otherwse, the user s responsble for any consequences that may possbly occur.

• Weldng cables should be kept as short as possble. They must move along the oor of the work area,

n a sde by sde manner.Weldng cables should not be wound n any way.

• A magnetc feld s generated on the machne durng weldng.Ths may cause the machne to pull

metal parts on to tself.To avod ths attracton, make sure that the metal materals are at a safe

dstance or fxed. The operator must be nsulated from all these nterconnected metal materals.

• In cases where the workpece cannot be connected to the ground due to electrcal safety, or because

of ts sze and poston (for example, n buldng marne vessel bodes or n steel constructon manu-

facturng), a connecton between the workpece and the groundng may reduce emssons n some

cases, t should be kept n mnd that groundng of the workpece may cause users to sustan njures

or other electrcal equpment n the envronment to break down. In cases where necessary, the work-

pece and the groundng connecton can be made as a drect connecton, but n some countres where

drect connecton s not permssble, the connecton can be establshed usng approprate capacty

elements n accordance wth local regulatons and ordnances.

• Screenng and sheldng of other devces and cables n the work area can prevent alasng eects.

Screenng of the entre weldng area can be evaluated for some specfc applcatons.

Evaluation Of Electromagnetic

Suitability Of The

Work Area

Electromagnetic Interferance

Reduction Methods

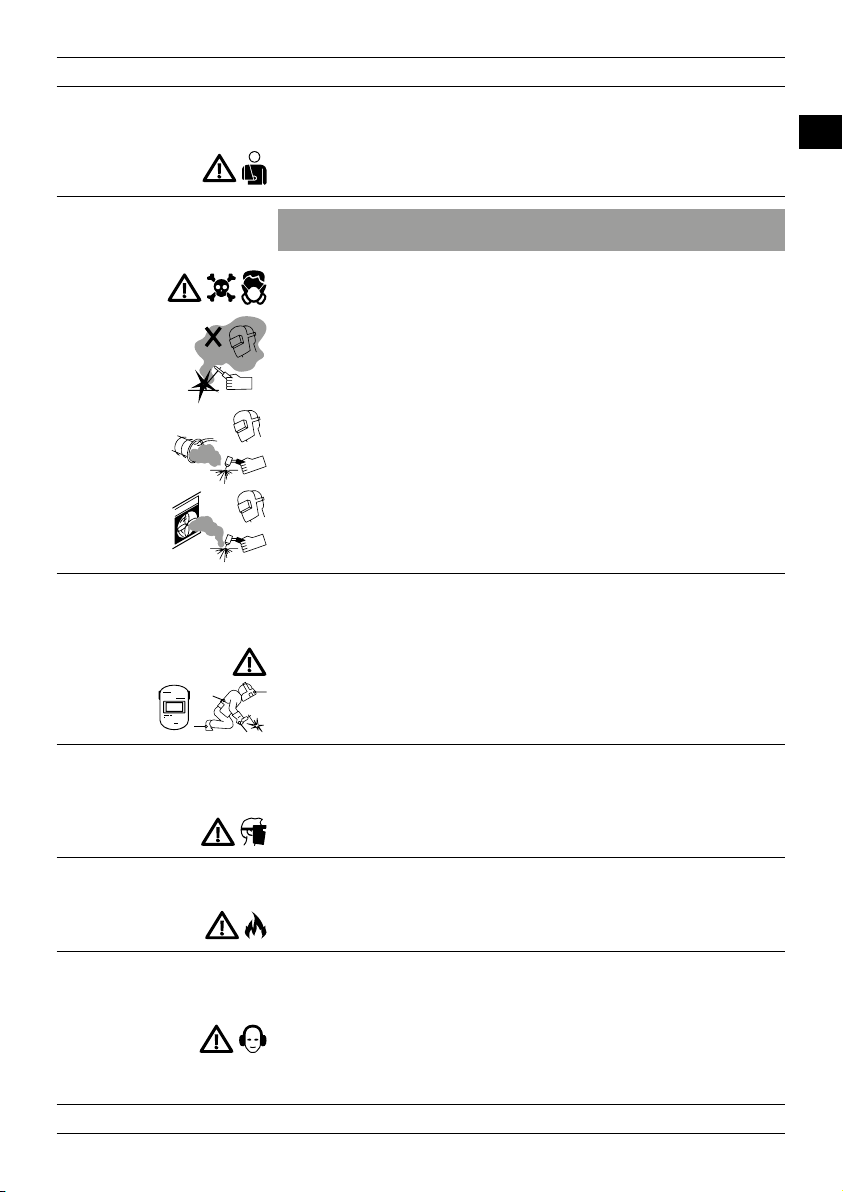

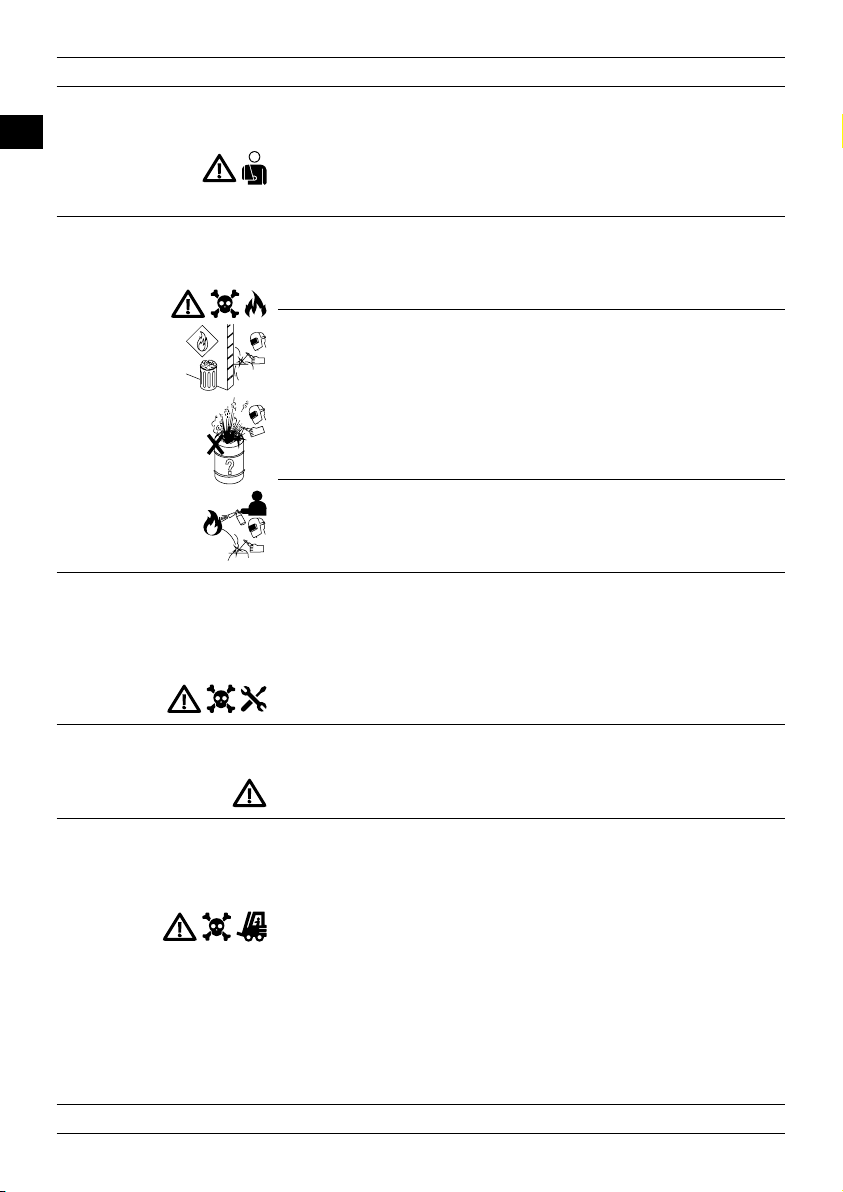

Safety Precautions