HPV1000-App_Note_27

Closed Loop Start Guide

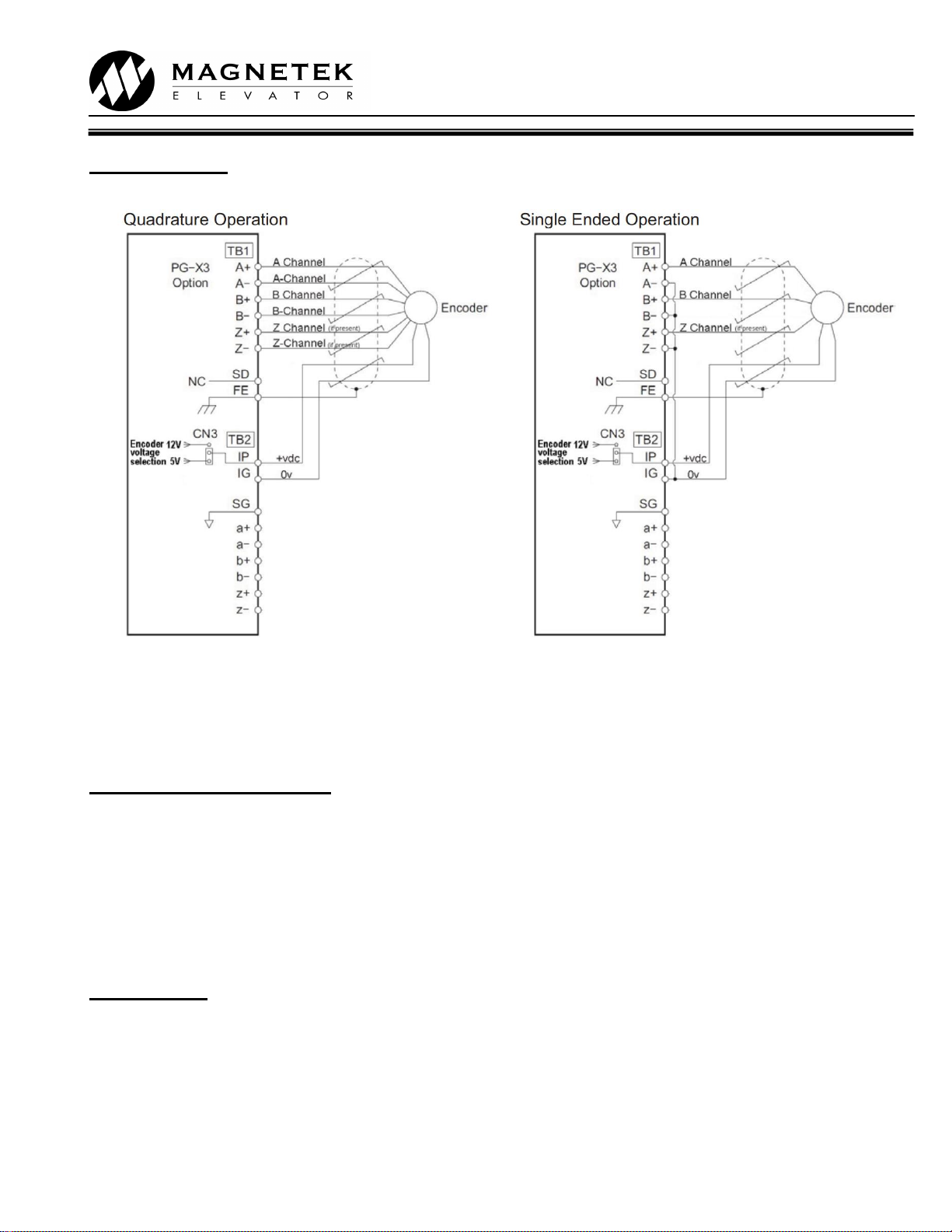

Encoder Set-up

6) Verify the encoder has been selected and installed in accordance with the following:

Electrical interference and mechanical speed modulations are common problems that can result in improper

speed feedback getting to the drive. To help avoid these common problems, the following electrical and

mechanical considerations are suggested.

IMPORTANT- Proper encoder speed feedback is essential for a drive to provide proper motor control.

Electrical Considerations

•If possible, insulate both the encoder case and shaft from the motor.

•Use twisted pair cable with shield tied to chassis ground at drive end

•Use limited slew rate differential line drivers.

•Do not allow capacitors from internal encoder electronics to case.

•Do not exceed the operating specification of the encoder/drive.

•Use the proper encoder supply voltage and use the highest possible voltage available. (i.e. 12VDC is

preferred because less susceptible to noise)

Mechanical Considerations

•Use direct motor mounting without couplings where possible.

•Use hub or hollow shaft encoder with concentric motor stub shaft.

•If possible, use a mechanical protective cover for exposed encoders.

Autotune

7) The autotune can now be performed by navigating to the ‘T’menu. The drive has several options for

autotuning the motor, however usually the motor will be roped, and so the ‘Tune-No Rotate1’ (Static) method

will be used.

If the ropes are off, and the motor can turn freely, the ‘Standard Tune’ (Rotating) method can be used.

Navigate to the Autotune menu and enter the following information:

•‘Tune-No Rotate1’ (TUNING MODE SEL(T1-01))

•Motor Rated Power in kW (MTR RATED POWER(T1-02))

•Rated Voltage in V (RATED VOLTAGE(T1-03))

•Rated Current in A (RATED CURRENT(T1-04))

•Rated Frequency in Hz (RATED FREQUENCY (T1-05))

•Number of Poles (NUMBER OF POLES(T1-06))

•Rated Motor Speed* (RATED SPEED (T1-07)) - This is after slip, so NOT synchronous speed.

•Encoder Pulses (ENCODER PPR (T1-08))

•No Load Current (NO-LOAD CURRENT(T1-09) - Enter 35% of the RATED MOTOR CURRENT entered

above for 4 pole motors or 45% for a 6 pole motor

*Note The rated motor rpm entered must

equal what it can achieve at rated frequency,

at full load and full speed. If synchronous

speed is given on the dataplate, a lower RPM

must be entered. Table 2 gives an indication

of typical motor rated rpm for lift applications.

Once the above information has been entered and the bottom of the menu is reached the screen will display:

‘Auto-tuning. Waiting for command –Tune Ready? Give Run/Hit Enter’.

At this point DO NOT press any keypad buttons.