Intelli-Protect User Manual

April 2023

Page 6 of 65

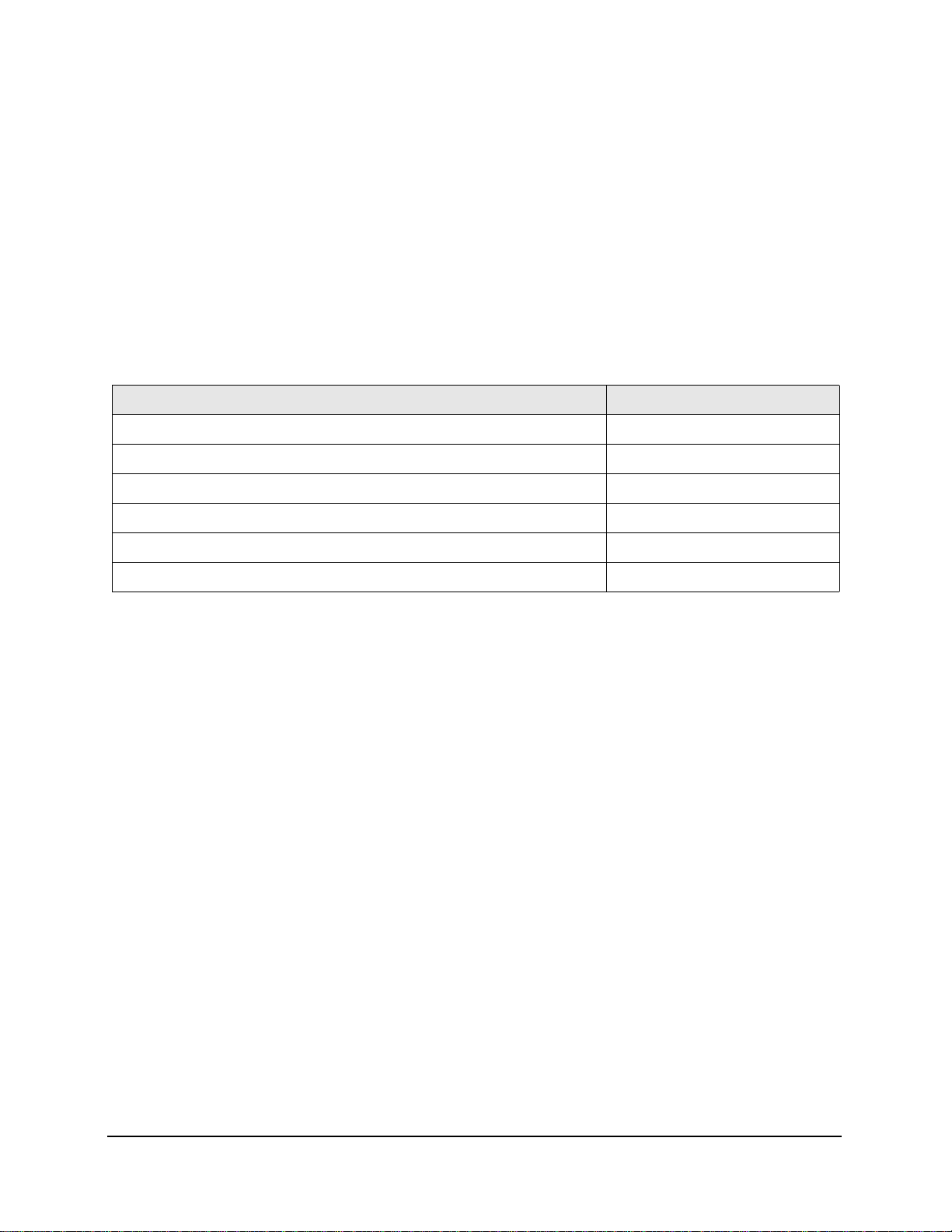

Table of Contents

1 Introduction...........................................................................................................................................8

1.1 Intelli-Protect® Products...............................................................................................................8

1.1.1 Intelli-Protect® Configurable No-Fly Zones.............................................................................9

1.1.2 Intelli-Protect® Fixed Location No-Fly Zones ........................................................................10

1.2 Intelli-Protect® Parts ..................................................................................................................11

1.3 Flexible Configurations with User Interface (UI).........................................................................11

1.4 Light Stack..................................................................................................................................12

2 Mechanical Installation .......................................................................................................................13

2.1 Environmental Ratings and Certifications ..................................................................................13

2.2 Laser Specification.....................................................................................................................14

2.3 Reflector Installation...................................................................................................................15

2.4 50 m Laser Installation and Wiring.............................................................................................16

2.4.1 50 m Laser Wiring..................................................................................................................17

2.5 150 m and 300 m Laser Installation and Wiring.........................................................................18

2.5.1 150 m and 300 m Laser Wiring..............................................................................................20

2.6 Laser Alignment Instructions......................................................................................................21

2.7 Fixed Location Installation: Windmill Switches...........................................................................21

2.7.1 Slowdown and Stop Configuration.........................................................................................22

2.7.2 Protected Zone Configuration................................................................................................23

2.8 Light Stack Installation ...............................................................................................................24

3 Power and Control Wiring...................................................................................................................26

3.1 Control Inputs.............................................................................................................................26

3.2 Intelli-Protect® Control Outputs..................................................................................................29

3.2.1 Control Outputs......................................................................................................................30

4 Configurable No-Fly Zone Setup ........................................................................................................31

4.1 Connecting to Web Server.........................................................................................................31

4.2 Configurable Initial Setup...........................................................................................................32

4.3 How to Configure Travel Limits ..................................................................................................33

4.3.1 Trolley Configuration Steps ...................................................................................................34

4.3.2 Bridge Configuration Steps....................................................................................................37

4.4 Zone Setup.................................................................................................................................40

4.4.1 Load Size Consideration........................................................................................................41

4.5 Enabling Zones ..........................................................................................................................42

4.6 Hoist Upper Limit and Machine Down Configuration..................................................................43

4.7 Slowdown Only Configuration ....................................................................................................44

4.8 Zone Overview...........................................................................................................................45

5 Fixed Location Setup..........................................................................................................................47

5.1 Connecting to Web Server.........................................................................................................47

5.2 Main Menu..................................................................................................................................48

5.3 Fixed Location Initial Setup........................................................................................................49

5.4 Fixed Location Test Procedure ..................................................................................................50

6 Intelli-Protect® Inputs and Outputs.....................................................................................................52

7 Troubleshooting..................................................................................................................................54

7.1 Light Stack Indicators and Corrective Actions............................................................................54

7.2 Alarms and Corrective Actions During Operation.......................................................................55

8 Magnetek Application Examples.........................................................................................................56

8.1 Connection Diagram with Magnetek Series 4 Drive...................................................................56

8.1.1 IMPULSE®·G+/VG+ Series 4 Drive Programming................................................................57

8.2 Hoist Upper Limit Switch............................................................................................................57

8.3 Machine Lowered Example........................................................................................................58

8.4 Slowdown Only Configuration ....................................................................................................59