WARNING! SUDDEN MOVEMENT HAZARD. The motor will spin

during a Rotational Auto-Tune.

WARNING! ELECTRIC SHOCK HAZARD. High voltage will be

supplied to the motor when Auto-Tuning is performed. Do not

touch the motor during Auto-Tuning.

Encoder Direction

Check the motor speed monitor U01-05

while turning the motor manually in forward

direction (CW). If the sign displayed is

negative, power down the VFD, wait at

least five minutes until the charge

indicator extinguishes completely, then

swap encoder wires A+ with A- on the

PG-X3 card. Next, power up the VFD and

repeat this test. Or, reverse the encoder

direction with parameter F01-02.

Frequently Asked Questions

Question: How do I reset the VFD parameters back to

factory default settings?

Answer: There are two options. Setting A01-05 = 1110

will revert the parameters to the settings saved at the

factory. Setting A01-05 = 2220 will revert all parameters

back to default.

Question: How do I adjust the time it takes the motion to

speed up or slow down?

Answer: Adjust the acceleration time parameter b05-01

and deceleration time parameter b05-02.

Question: How do I prevent the occurrence of an OV

fault (overvoltage) while my motor is ramping down?

Answer:

Increase deceleration time parameter b05-02

and check braking resistor.

Question: How do I prevent the occurrence of an OL1

fault (overload) while my motor is ramping down?

Answer: Verify motor rated current parameter E02-01

and motor overload protection time parameter L01-02.

Question: How can I run my motor above the base

motor speed?

Answer: Increase the value of parameter E01-04

Maximum Frequency. For hoists, the Ultra-Lift feature is

recommended. Verify that the motor and system allow

for this.

Question: How can I change motor direction without

changing the motor leads?

Answer: Set parameter b03-04 = 1 (exchange phases).

Question: What should I do when the VFD detects a

brake failure and displays a BE6 or BE8 fault?

Answer: Do not turn off power! Lower the load to the

ground and inspect the brakes.

Question: On no load brake (NLB) hoist applications,

why does the brake stay open temporarily at the end of a

run?

Answer: This feature is called Load Float and reduces

wear on the brakes. See parameter C08-10 to adjust the

time.

Question: Where can I find troubleshooting information

regarding faults and alarms?

Answer: Reference the technical manual.

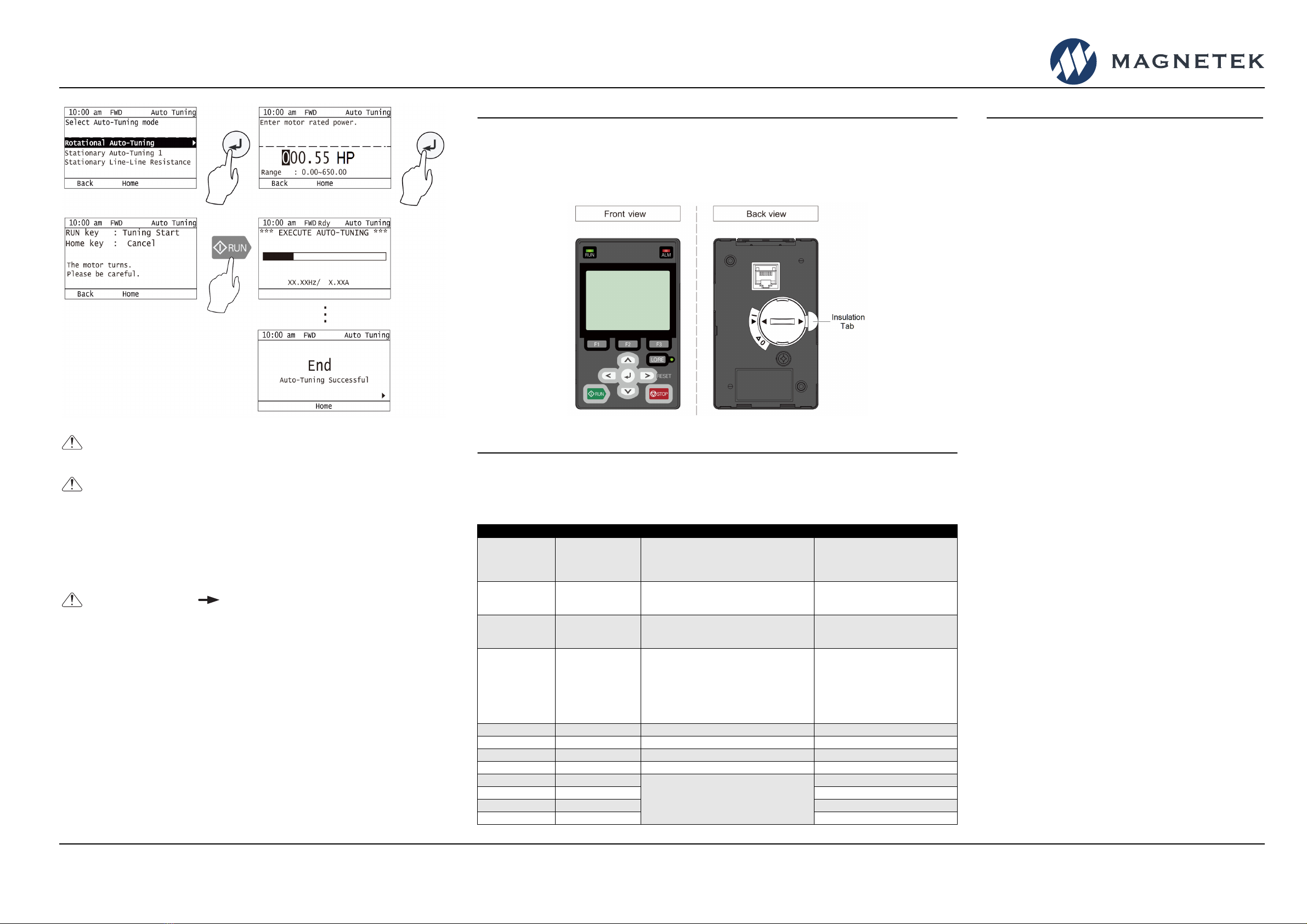

Step 9

Remove Keypad Insulation Tab

Detach the keypad and pull the insulation tab located on the back, next to the battery compartment.

The battery will now maintain the date and time settings.

Refer to Step 4 for the location of the Set Date/Time menu.

Step 10

Quick Start Parameters

The following table lists commonly used parameters as well as frequently asked questions.

Refer to Step 4 for the location of the parameters.

Parameter Description Settings Comments

A01-01 Access Level 0 = Operation

1 = User

2 = Advanced (Default)

3 = Expert

Advanced level contains the most

commonly used parameters and

hides the rest. Expert level contains

every available parameter.

A01-02 Control Method 0 = V/f

2 = Open Loop Vector*

3 = Closed Loop Vector*

* Auto-Tune Recommended

A01-03 Motion 0 = Traverse

1 = Hoist w/ Load Brake (G+ only)

2 = Hoist w/o Load Brake (VG+ only)

A01-04 Speed Reference 0 = Two-Speed Multi-Step

1 = Three-Speed Multi-Step

2 = Five-Speed Multi-Step

3 = Two-Step Infinitely Variable

4 = Three-Step Infinitely Variable

5 = Uni-Polar Analog (0-10VDC, 4-20mA)

6 = Bi-Polar Analog (-10 – +10VDC)

b01-01 – b01-16 Speed References 0.00 - 300.00 Hz Limited by E01-04

b05-01 Acceleration Time 0.0 - 60.0 Seconds

b05-02 Deceleration Time 0.0 - 60.0 Seconds

E02-01 Motor Rated FLA Dependent on o02-04 Setting See Motor Nameplate

H01-xx Digital Inputs

See Technical Manual for Settings

Terminals S1 - S8

H02-xx Digital Outputs Terminals M1-M2, M3-M4, M5-M6

H03-xx Analog Inputs Terminals A1, A2, A3

H04-xx Analog Outputs Terminals AM, FM

IMPULSE®•G+/VG+ Series 5 Variable Frequency Drive

Quick Start Guide

www.cmco.com/magnetek

IMPULSE•G+/VG+ Series 5 Quick Start Guide

144-80081 R0

August 2023 © Copyright 2023 Magnetek

N49 W13650 Campbell Drive

Menomonee Falls, WI 53051

Phone: 262.783.3500

Fax: 262.783.3510

Toll-Free Phone: 800.288.8178

Toll-Free Fax: 800.298.3503

For questions regarding service or technical information contact:

1.833.SVC.CMCO (1.833.782.2626)

International Service

Outside the U.S. & Canada call 1.262.783.3500, press 3