3

TABLE OF CONTENTS

Page

INTRODUCTION ..............................................................................................................................2

TABLEOFCONTENTS ...................................................................................................................3

SAFETYNOTES.............................................................................................................................4

OPERATINGSAFETY.....................................................................................................................4

ENGINESAFETY ...........................................................................................................................5

SERVICESAFETY .........................................................................................................................5

TOWINGSAFETY ..........................................................................................................................6

UNITSERIALNUMBERLOCATIONS ..............................................................................................6

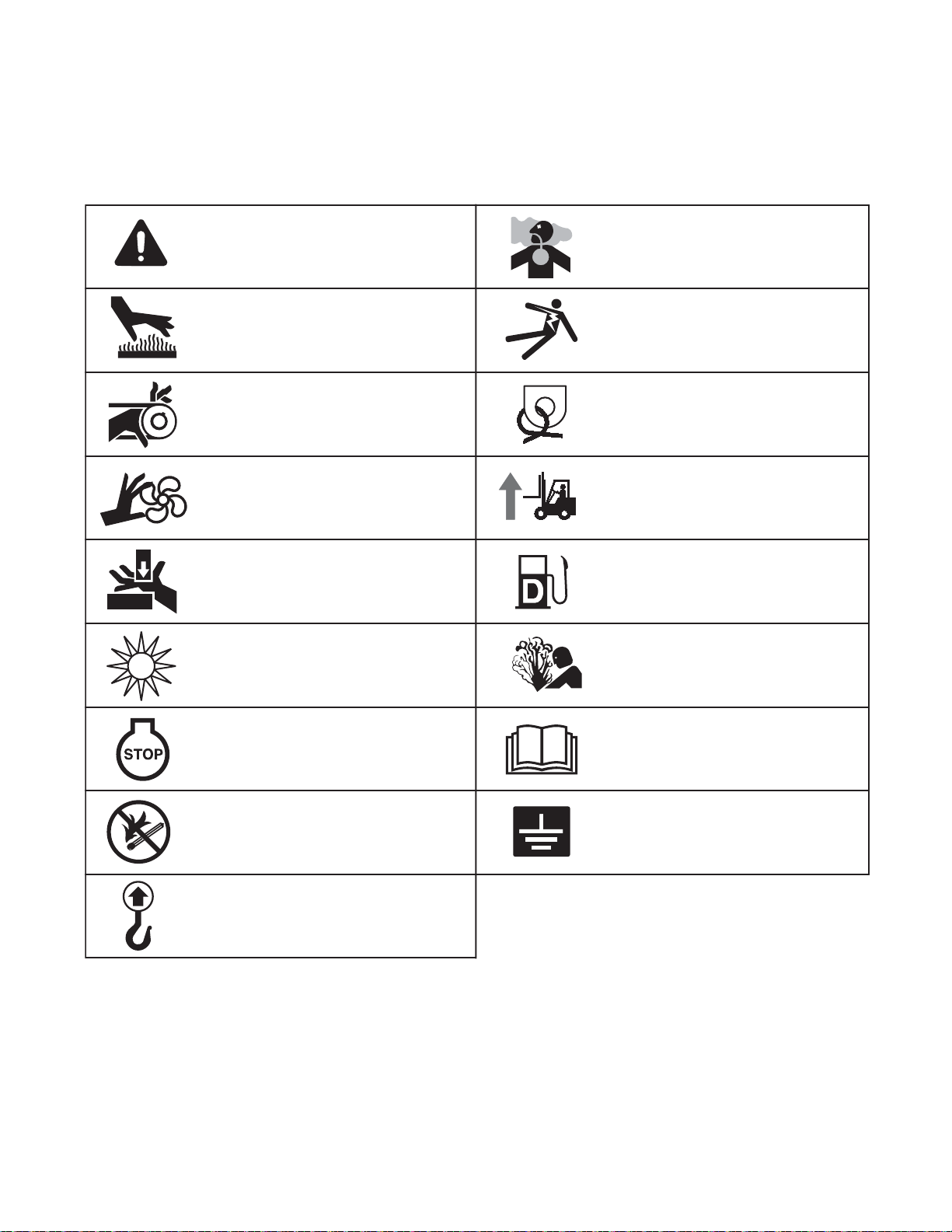

SAFETYSYMBOL SUMMARY.......................................................................................................7

SPECIFICATIONS ....................................................................................................................8 - 11

LIGHTTOWERSET UP ................................................................................................................12

RAISINGTHE TOWER.......................................................................................................... 12 - 14

MAINCONTROLPANELCOMPONENTS .....................................................................................15

ENGINESTARTINGANDOPERATION .........................................................................................16

AUTOMATICSHUTDOWN ............................................................................................................16

LIGHTOPERATION.......................................................................................................................17

AUXILIARYOUTLETS ...................................................................................................................17

VOLTAGEREGULATION(OPTIONAL) ..........................................................................................17

DERATINGFORALTITUDE ...........................................................................................................18

SHUTTINGDOWN ........................................................................................................................18

LOWERINGTHE TOWER......................................................................................................18 - 19

TOWINGTHETRAILER ................................................................................................................19

LIFTINGTHETRAILER..................................................................................................................20

DAILYINSPECTION......................................................................................................................20

TRAILERWHEELBEARINGS ......................................................................................................21

ENGINEMAINTENANCE ..............................................................................................................22

OPTIONALLOWERRADIATORHOSEHEATERUSEANDMAINTENANCE................................23

TROUBLESHOOTINGTHELIGHTS ..............................................................................................23

MASTLIGHT CONNECTIONS .......................................................................................................24

UNITDECALS........................................................................................................................24 - 28

GENERATORASSEMBLY6 kW...................................................................................................29

GENERATORASSEMBLY8 kW...................................................................................................30

GENERATORASSEMBLY8 kW WITH VOLTAGE REGULATION .................................................31

MANUALWINCH MASTASSEMBLY.....................................................................................32 - 33

ELECTRICWINCHMASTASSEMBLY ..................................................................................34 - 35

ENCLOSUREASSEMBLY .....................................................................................................36 - 37

FRAMEASSEMBLY ..............................................................................................................38 - 40

MASTJUNCTIONBOXASSEMBLY,QUICKDISCONNECTLIGHTS .............................................41

MASTJUNCTIONBOXASSEMBLY,HARDWIREDLIGHTS .........................................................42

MASTJUNCTIONBOXASSEMBLY,6LIGHTQUICKDISCONNECT.............................................43

MITSUBISHIENGINE.............................................................................................................44 - 45

KUBOTAENGINE ..................................................................................................................46 - 47

CONTROLBOXAND PANELASSEMBLY..............................................................................48 - 49

LIGHTASSEMBLY.................................................................................................................50 - 51

METALHALIDEBALLASTBOXASSEMBLY ................................................................................52

HIGHPRESSURESODIUMBALLASTBOXASSEMBLY..............................................................53

WIRINGDIAGRAMS ..............................................................................................................51 - 59