iv

Sensor .............................................................................................................................. 50

XY Mover.......................................................................................................................... 50

Embosser ......................................................................................................................... 51

MCP Commands .............................................................................................................. 51

3.9: Common Error Messages ............................................................................................. 54

Section 4: Removal and Replacement .................................................................................... 57

4.1: Covers........................................................................................................................... 57

4.2: Embosser Assembly ..................................................................................................... 62

4.3: XY Assembly................................................................................................................. 64

4.4: Exit Assembly................................................................................................................ 66

4.5: Printer Assembly ........................................................................................................... 68

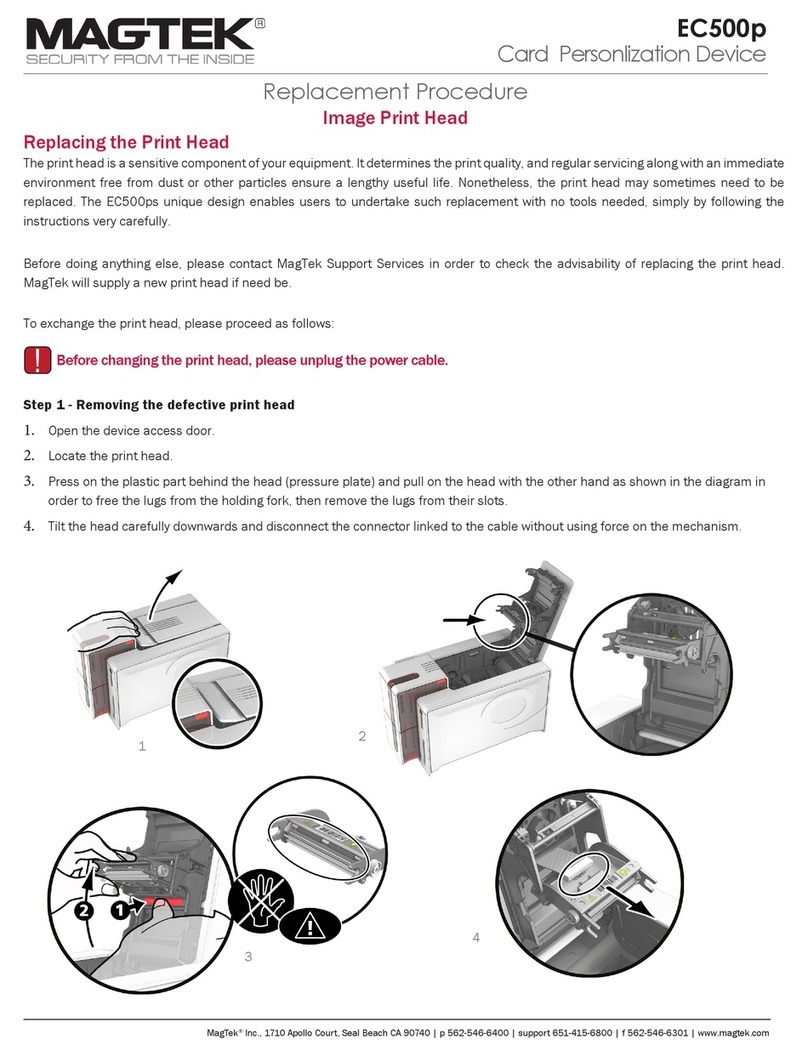

Printhead Replacement .................................................................................................... 70

Setting the Print TOF........................................................................................................ 72

Setting the Print EOF........................................................................................................ 73

Adjusting the Image Darkness.......................................................................................... 74

Adjusting the Vertical Image Position from the Driver....................................................... 74

4.6: Sliding Tray Assembly................................................................................................... 75

4.7: 24-Volt Power Supply.................................................................................................... 81

4.8: MagnePrint Swipe Reader (MSR) Rail.......................................................................... 82

4.9: Monitor Replacement .................................................................................................... 83

Section 5: Parts Catalog .......................................................................................................... 87

5.1: Covers Assembly .......................................................................................................... 88

Top Cover......................................................................................................................... 89

Front Cover with Display .................................................................................................. 90

Left Cover......................................................................................................................... 91

Left Top Cover Latch Assembly ....................................................................................... 92

Right Cover ...................................................................................................................... 93

Right Top Cover Latch Assembly ..................................................................................... 94

Card Access Door Latch Assembly .................................................................................. 95

5.2: Chassis Assembly......................................................................................................... 96

Outer Components of Chassis ......................................................................................... 97

Inner Components of Chassis .......................................................................................... 98

5.3: Embosser Assembly ................................................................................................... 100

Top Half of Embosser..................................................................................................... 101

Embosser Wheel ............................................................................................................ 103

Bottom Half of Embosser................................................................................................ 104

Embosser Base .............................................................................................................. 106

5.4: X-Y Transport Assembly ............................................................................................. 107

Y Portion of Assembly .................................................................................................... 108

XY Carriage.................................................................................................................... 110

Card Clamp Assembly.................................................................................................... 112

5.5: Exit Transport Assembly ............................................................................................. 114

Eject Card Slide.............................................................................................................. 115

Card Transport (Left Side).............................................................................................. 116

Card Transport (Right Side) ........................................................................................... 118

Card Transport (Center) ................................................................................................. 120