SEWOO SLK-TL20X Series User manual

TE20X Series ENG Rev. 07/2023

Aroot Co., Ltd.

28-6, Gajangsaneopdong-ro, Osan-si, Gyeonggi- do, 18103, Republic of Korea

TEL : +82-31-8077-5000 / FAX : +82-31-624-5310

http://www.miniprinter.com

All specications are subject to change without notice

MODEL : SLK-TL20X Series

Receipt Printer User’s Manual

This device co mplies with part 15 of the FCC Rules.

Operation is subject to the following two conditions.

1) This device may not cause harmful interference, and

2) This device must accept any interference received,

including interference that may cause undesired operation.

Vic Barczyk

20280 S. Vermont Ave. STE 200, Torrance, CA 90502 | USA

+310-561-8030

Victor Almazan

Paseo de la Reforma No. 265 Piso 2.Ocina SBC. Col.

Cuauhtémoc, C.P. 06500 Ciudad de Mexico | Mexico

LA_Sales@miniprinter.com

Disposal of Old Electrical&Electronic Equipment(Applicable in the European Union and other Euro-

pean countries with separate collection systems)

This symbol on the product or on its packaging indicates that this product shall not be treated as household

waste. Instead it shall be handed over to the applicable collection point for the recycling of electrical and

electronics equipment. For more detailed information about recycling of this product, please contact your

local city oce, your household waste disposal service or the shop where you purchased the product.

10. Printer Cleaning 21

11. Linerless Printer 22

11-1. Linerless Printer Cleaning 22

11-2. Recommended Paper 22

12. Specications 23

13. Command List 25

14. Utilities 27

15. SW 28

Table of Contents

1. Parts Identications 3

2. Setting up the printer 4

2-1. Unpacking 4

2-2. Connecting the cables 5

2-2-1. Interface Connector 6

2-2-2. Cash Drawer Connector 8

2-3. Loading the Roll paper 9

2-4. Adjustment of paper width 12

3. Control panel and other functions 13

3-1. Control panel 13

3-2. Error indicators 13

4. Self Test 14

5. ASCII Print 15

6. ECO Mode 15

6-1. Font 15

6-2. Paper Reduce 16

6-3. Density 16

7. Printer Setting 17

7-1. Baudrate 17

7-2. Cutter 17

7-3. Error Beep 17

7-4. Melody 18

8. Hexadecimal Dump 19

9. Peripherals Connection 20

9-1. Bluetooth Connection (Option) 20

9-2. Wi-Fi Connection (Option) 20

4

34

3

2. Setting Up the Printer

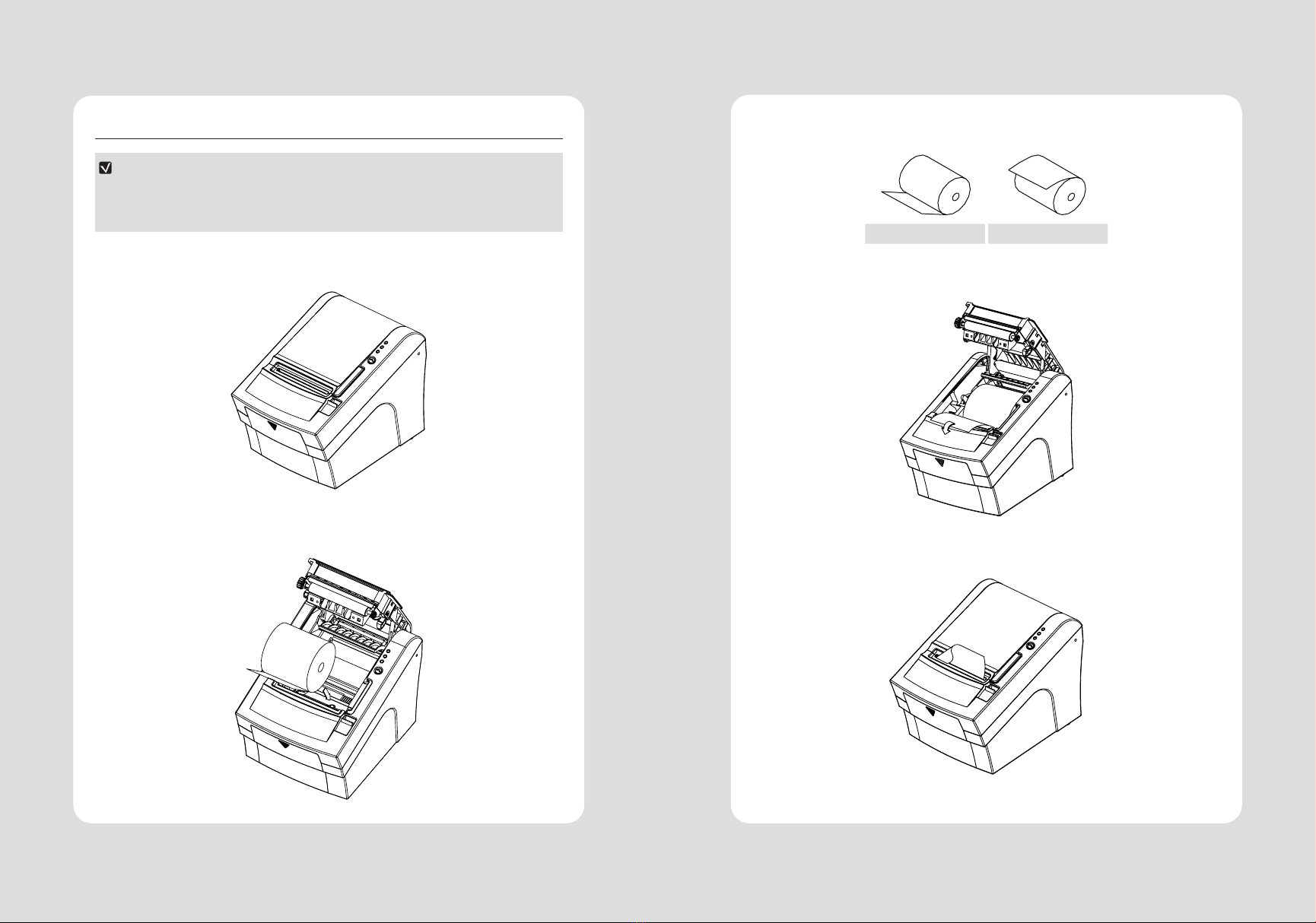

2-1. Unpacking

Your printer box should include these items. If any items are damaged or missing, please contact

your dealer for assistance.

The Printer CD Roll Paper

Interface Cable(optional) Adaptor(Optional)

Cleaning pen(Optional)

1. Parts Identications

POWER SWITCH

COVER OPEN LEVER

CONTROL PANEL

Used to turn on/off

power to the printer.

Pull down this lever to

open the printer cover.

Features LED indicators to indicate printer

status and switches to operate the printer.

PRINTER COVER

Open this cover to

load or replace paper.

6

56

5

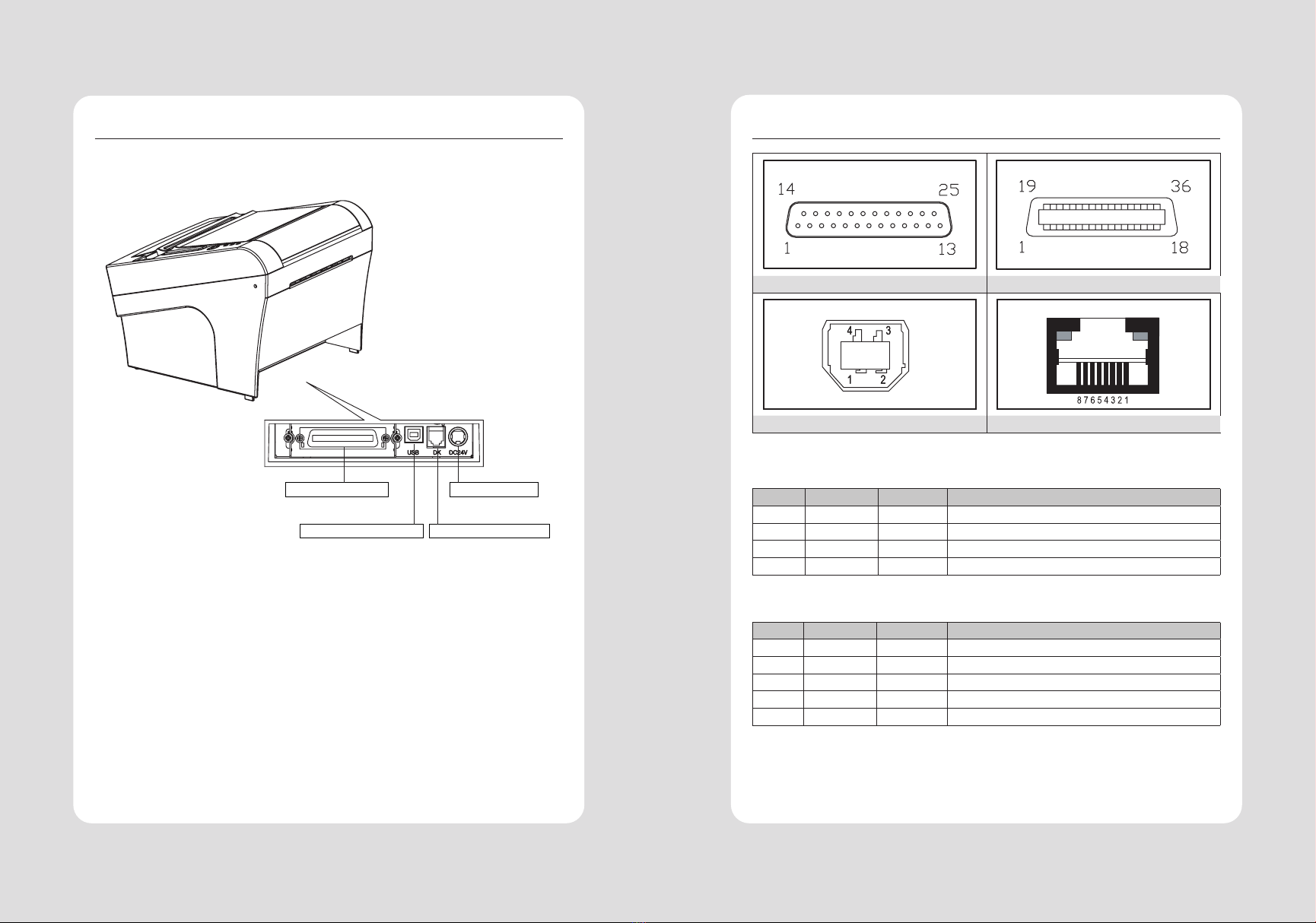

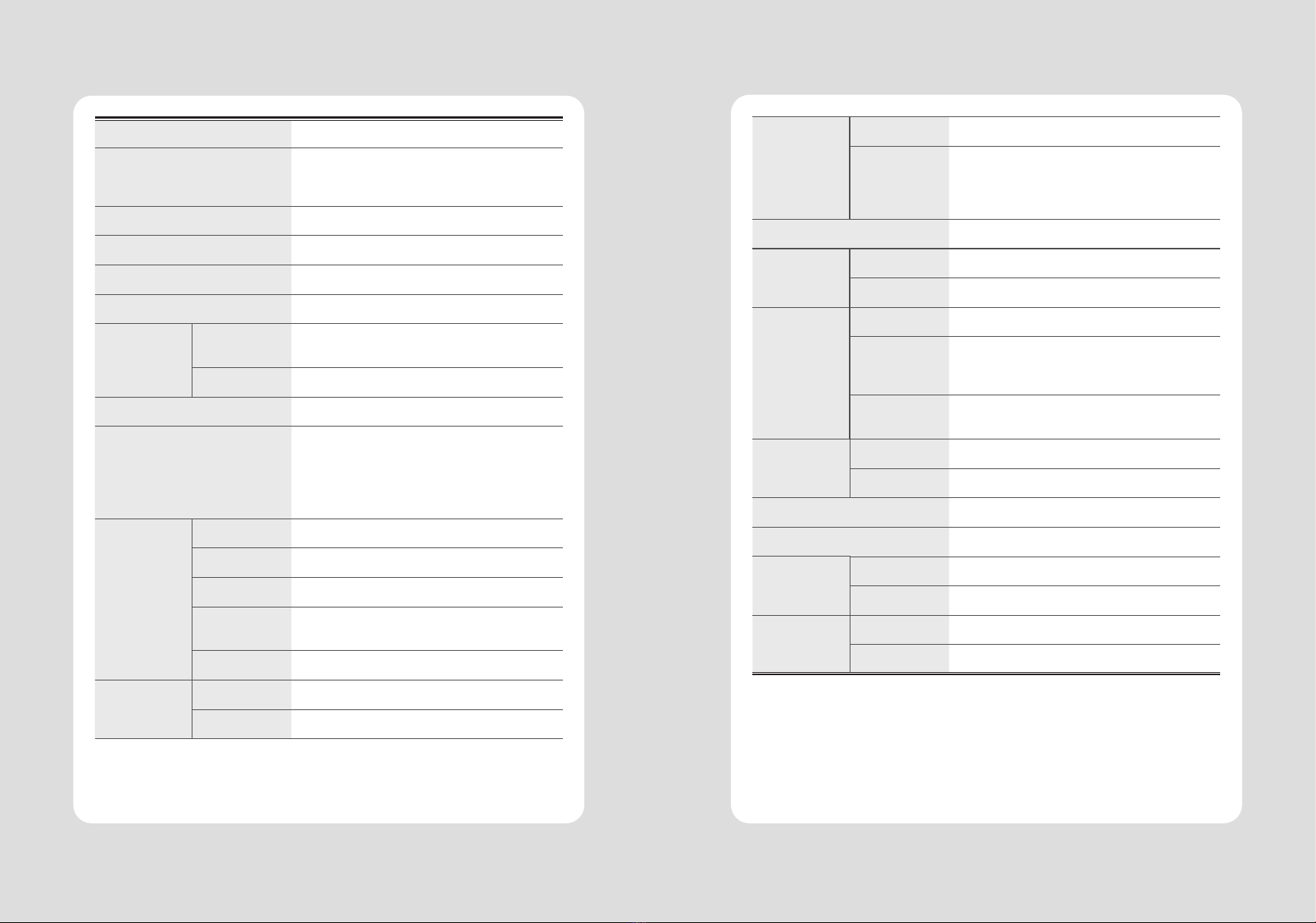

2-2-1. Interface Connector

D-SUB 25 Female Serial Centronics Parallel

Link LED Status LED

USB “B” Type Ethernet

USB Interface

PIN SIGNAL I/O DESCRIPTION

1 +5V - +5V

2DATA- - Printer transmit data line

3DATA+ - Printer transmit data line

4 GND - System Ground

Serial Interfaced

PIN SIGNAL I/O DESCRIPTION

2TxD Output Printer transmit data line RS-232C level

3 RxD Input Printer receive data line RS-232C level

4, 20 DTR Output Printer handshake to host line RS-232C level

6 DSR Input Data Send Ready

1, 7 GND - System Ground

2-2. Connecting the Cables

You can connect up the cables required for printing to the printer.

They all connect to the connector panel on the back of the printer, which is shown below :

INTERFACE CONNECTOR POWER CONNECTOR

CASH DRAWER CONNECTOR

INTERFACE CONNECTOR(USB)

Before connecting any of the cables, make sure that both the printer and the computer are turned

o.

8

78

7

2-2-2. Cash Drawer Connector

The printer can operate two cash drawers with a 6 pin RJ-11 modular connector.

The driver is capable of supplying a maximum current of 1.0 A for 510ms or less when not printing.

PIN SIGNAL Description

1Signal GND -

2Drawer kick-out drive signal 1 Output

3Drawer open/close signal Input

4+24V -

5Drawer kick-out drive signal 2 Output

6Signal GND -

Centronics Parallel Interface

PIN SIGNAL I/O DESCRIPTION

1 STROBE- Input Synchronize signal Data received

2~9 DATA0~7 Input/

Output Data bit Transmitted 0~7

10 ACK- Output Data receiving completed.

11 BUSY Output Impossible to print of data receiving.

12 PE Output Paper empty

13 SELECT Output Printer status for ON/OFF line

14 AUTO FEED- Input Paper auto feed signal

15 GROUND - System ground

16 GROUND - System ground

17 NC -

18 LOGIC-H - +3.3V

19~30 GROUND - System ground

31 INIT- Input Initialize

32 ERROR- Output Printer error

33 GROUND - System ground

34 NC -

35 NC -

36 SELLECT IN- Input Printer select signal

Ethernet Interface

PIN SIGNAL I/O

1 Data Out + Output Data +

2 Data Out - Output Data -

3 Data IN + Input Data +

4N.C

5N.C

6 Data IN - Input Data -

7N.C

8N.C

10

910

9

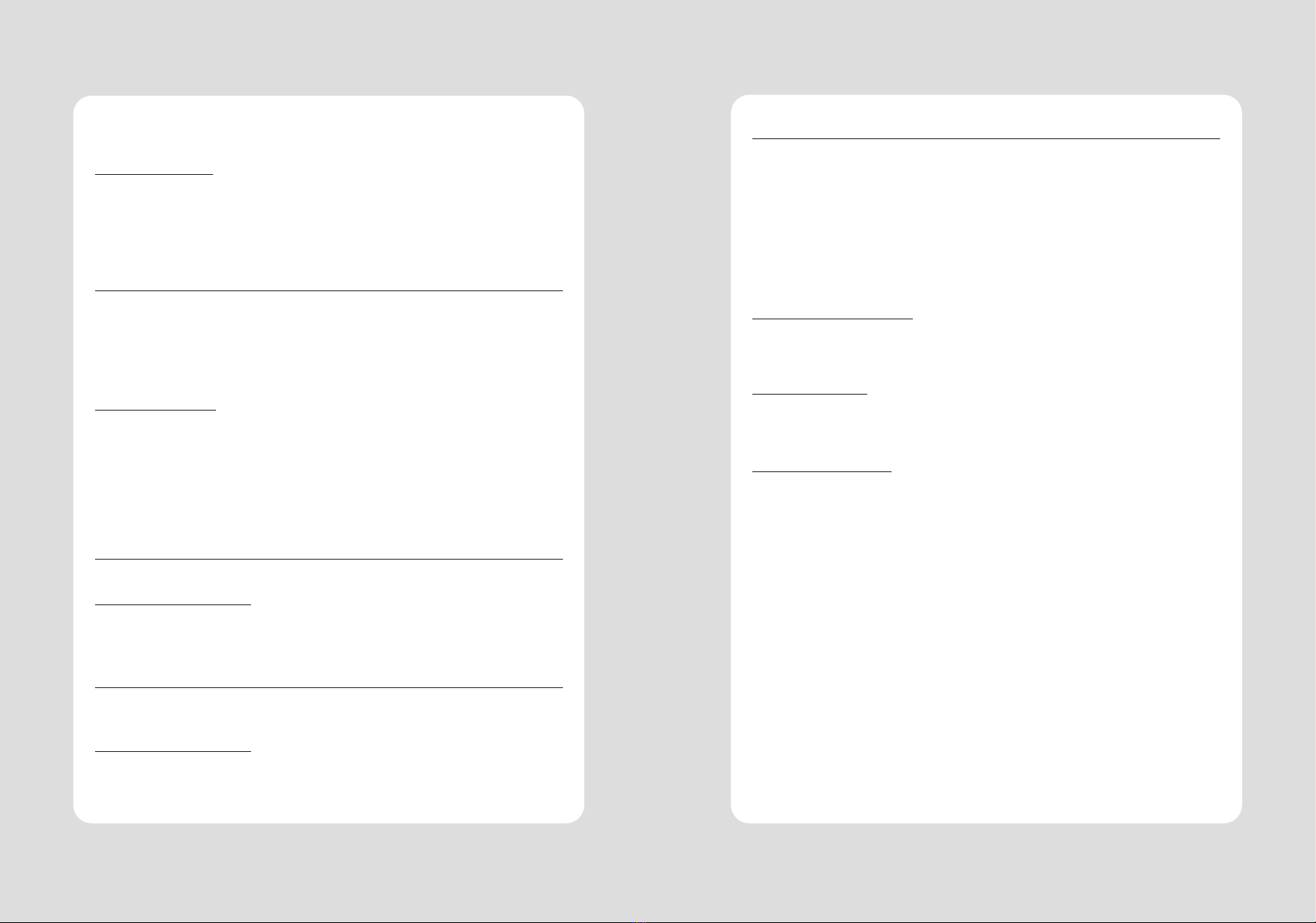

5 Be sure to note the correct direction that the paper comes o the roll.

X O

6 Pull out a small amount of paper, as shown. Then, close the cover.

7 Tear o the paper as shown.

2-3. Loading the Roll paper

NOTE

Be sure to use paper rolls that meet the specications. Do not use paper rolls that have the

paper glued to the core because the printer cannot detect the paper end correctly.

(Turn o power switch)

1 Make sure that the printer is not receiving data; Otherwise, data may be lost.

2 Open the paper roll cover by pushing down the cover open button.

3 Remove the used paper roll core if there is one inside.

4 Insert new paper roll as shown.

12

11 12

11

2-4. Adjustment of paper width

1 Please adjust the Paper Guide to t to the paper width as the direction of arrow.

2 Tight the screw after adjusting the Paper Guide.

3 Pull the edge of paper once the paper roll is installed correctly and close the Paper Cover.

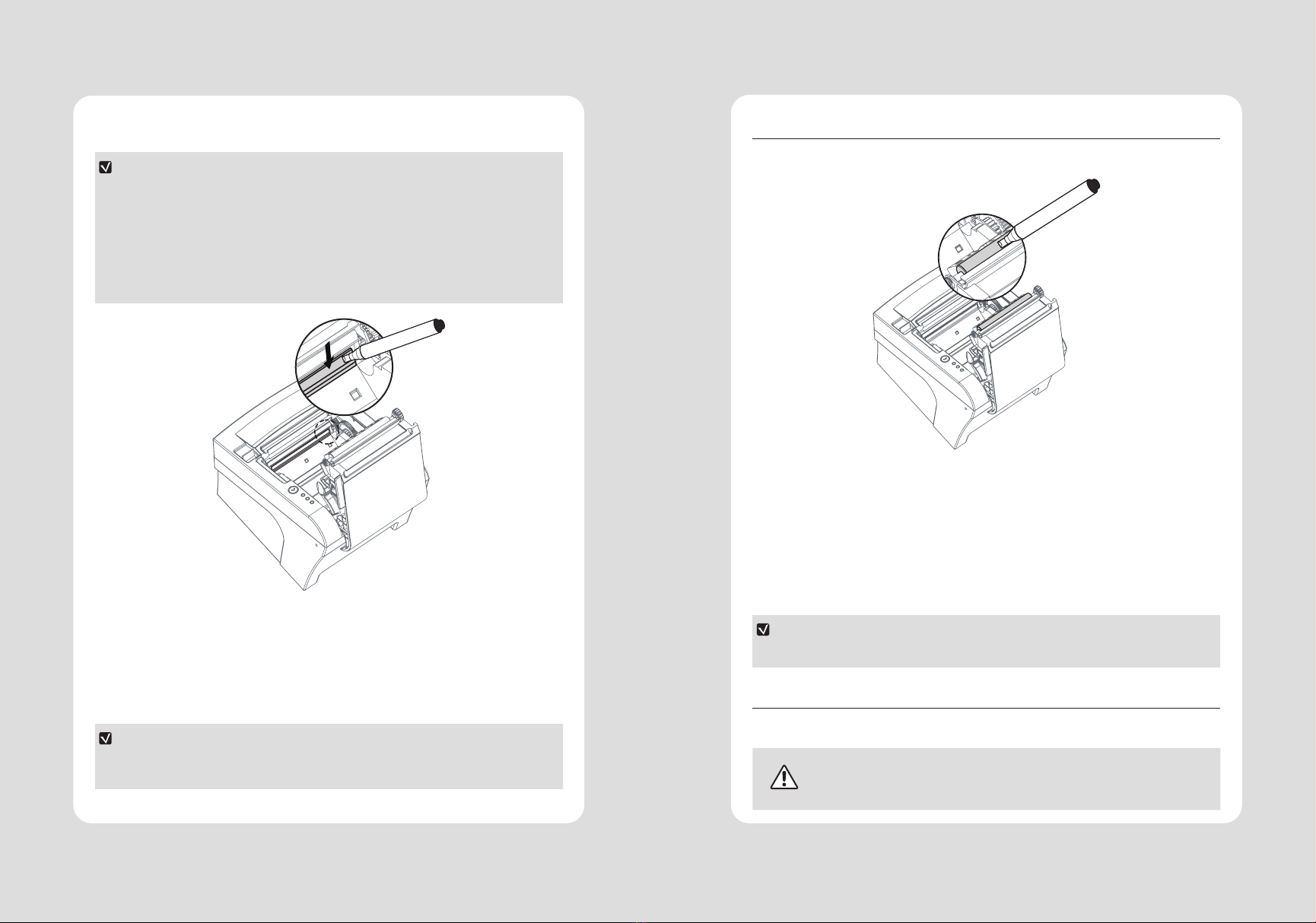

CAUTION:

When the paper is jammed with cutter, the top cover might be stuck. In this case, repeat power on

and o several times.

If the top cover is still stuck, please follow the steps to release the papers from jamming.

1 Make sure the printer is turned o.

2 Take out DIP switch cover as shown.

3 Turn screw with drivers to a direction until paper is released from the cutter.

14

13 14

13

4. Self Test

The self-test result indicated whether the printer is operating properly. Also with this, user can

check following options or status of the printer.

Control circuit

Printer mechanism

Printing quality

ROM version

Interface setting

This test is independent of any other equipment or software.

Running the self test

1 Make sure the printer is turned o and the printer cover is closed properly before performing

the self test.

2 Turn the printer on holding the FEED button, then the self-test will start.

The self-test prints the printer setting value and then prints the following, and pauses. (Error

LED On)

SELECT MODE BY BUTTON

1. ASCII PRINT

2. SELECT BAUDRATE MODE

3. HEXADUMP MODE

3 Press the FEED button consecutively (1~3)

1. ASCII PRINT

(press the FEED button once)

Printing test page constructed with ACII code.

2. SELECT BAUDRATE MODE

(press the FEED button twice)

Set the speed of Serial Interface

(You can set the BAUDRATE in this mode)

3. PRINTER SETTING

(press the FEED button triple time)

Set the printer option.

(Serial baudrate, Cutting mode, Error beep, Melody)

3. HEXADUMP MODE

(press the FEED button quad time)

Printing the HEX value received from the interface

※ Wait for 5~6 seconds if you want to exit. Printer performs a cutting when exiting this mode

4 The printer is ready to receive data after nishing setting.

3. Control panel and other functions

3-1. Control panel

You can control the basic paper feeding operations of the printer with the button on the control

panel. The indicator lights help you to monitor the printer’s status.

Control Panel

Button

The button can be disabled by the ESC c 5 command.

Press the FEED button once to advance paper one line. You can also hold down the FEED button

to feed paper continuously.

3-2. Error indicators

This section explains the dierent patterns signaled by the three LED indicators located on the top

cover of the printer.

STATUS

PAPER ERROR POWER

REMARKS

RED RED GREEN

Power o OFF OFF OFF Normal power is not supplied to the printer

Power on OFF OFF ON Normal power is supplied to the printer

On line OFF OFF ON Normal error-free mode

Cover open OFF ON ON Close cover

Paper empty OFF ON ON Insert new paper roll

Paper near end ON OFF ON Paper is low

Test mode OFF OFF ON Ignored error led

16

15 16

15

6-2. Paper Redue

Reduce menu (Line space, Line feed, barcode[1D] height) was developed for

paper saving.

Line space

”Line space"

means the amount of feed when you intentionally generate newlines.

Line feed

”Line feed"

means the amount of feed when there is an automatic line break.

Barcode Height

”Barcode H eight”

means the height of the barcode when creating a one-dimensional barcode.

LINE SPACE SETTING

1. NORMAL

2. REDUCE 50%

3. REDUCE 75%

4. REDUCE 90%

LINE FEED SETTING

1. NORMAL

2. REDUCE 50%

3. REDUCE 75%

4. REDUCE 90%

1D BARCODE HEIGHT SETTING

1. NORMAL

2. REDUCE 50%

3. REDUCE 75%

4. REDUCE 90%

6-3. Paper Redue

Adjust the print density to save the power consumed by the printer.

SELECT DENSITY

1. NORMAL

2. LOW

3. DARK

5. ASCII Print

6. ECO Mode

ASCII PRINT is printing a test page constructed ASCII code. You can able to check the printer works

properly with this

The ASCII PRINT test automatically ends and cuts the paper after printing the following:

*** Completed ***

The printer is ready to receive data as soon as it completes the ASCII PRINT.

After entering the ECO MODE, the list which can select the ECO option will be

printed. Similar like Self Test, you can press the FEED button to select a ECO option.

Once the input performs properly, the printer shows a result and store.

ECO MODE

1. FONT SETTING

2. LINE SPACE SETTING

3. LINE FEED SETTING

4. BARCODE[1D] HEIGHT

5. DENSITY SETTING

6-1. Font

FONT SETTING menu can be change the Font mapping(FONT A / FONT B).

If you did not want other side font, you can disable that.

- FONT A : 12x24

- FONT B : 9x17

FONT SETTING

1. FONT A -> A / FONT B -> B

2. FONT A -> B / FONT B -> B

3. FONT A -> A / FONT B -> A

4. FONT A -> B / FONT B -> A

18

17 18

17

7-4. Melody

To DK Port (Cash), Melody box or external buzzer can be connected.

You can activate it from the Melody Setting menu, and the melody will operate

after the cutting operation.

- Melody Box : Melody is xed and volume can be adjusted.

- External Buzzer : 3 types of melody are output according to the Melody Type

setting and volume control is not included

SELECT MELODY OPTION

1. MELODY SETTING

2. SELECT MELODY TYPE

MELODY SETTING

1. MELODY ON AFTER CUTTING

2. MELODY OFF

SELECT MELODY TYPE

1. MELODY-Ⅰ

2. MELODY-Ⅱ

3. MELODY-ⅢW

Change the printer settings. The options below can also be changed via the

Memory Saver.

PRINTER SETTING

1. SELECT BAUDRATE

2. SELECT CUTTING MODE

3. SELECT ERROR BEEP OPTION

4. SELECT MELODY OPTION

7-1. Baudrate

After entering the BAUDRATE MODE, the list which can select the BPS will be

printed.

Similar like Self Test, you can press the FEED button to select a BAUDRATE.

Once the input performs properly, the printer shows a result and store.

The printer is ready to receive data as soon as it completes the SELECT

BAUDRATEMODE.

SELECT BAUDRATE

1. 4800bps

2. 9600bps

3. 19200bps

4. 38400bps

5. 57600bps

6. 115200bps

7-2. Cutter

Set cutter mode.

SELECT CUTTING MODE

1. PARTIAL CUT

2. FULL CUT

7-2. Error Beep

If the cover is open or there is no paper, the error beep function is activated.

This option allows you to enable / disable the error beep.

SELECT CUTTING MODE

1. BEEP ON

2. BEEP OFF

7. Printer Setting

20

19 20

19

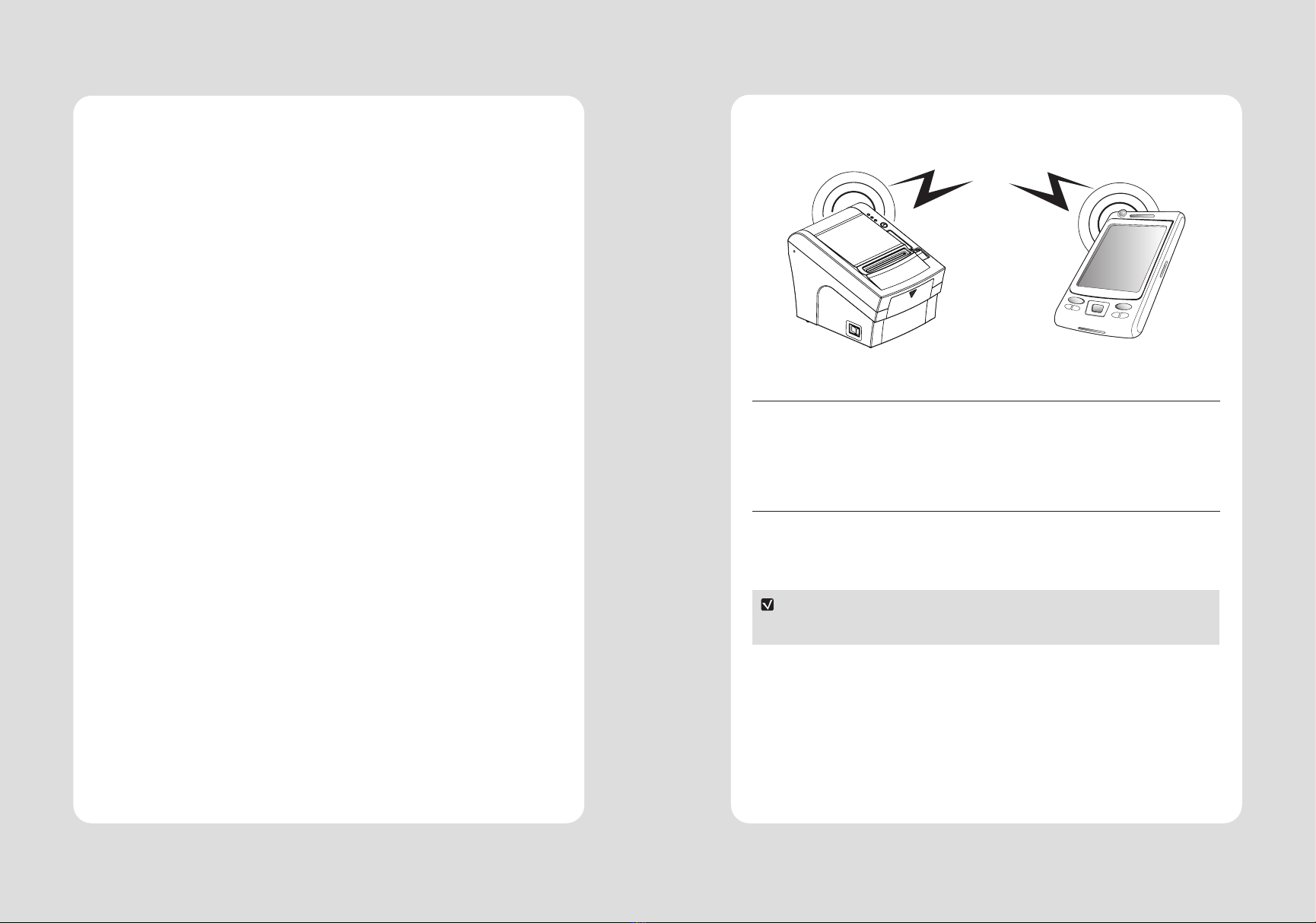

9. Peripherals Connection

This product can communicate with other devices via Bluetooth or Wi-Fi communication and

cable.

9-1. Bluetooth Connection (Optional)

1 The Printer can be connected to devices equipped with Bluetooth communication capacity

(PDAs, PCs, etc.)

2 Use the Bluetooth connection function supported by the device to connect to the printer.

9-2. Wi-Fi Connection (Optional)

1 The Printer can be connected to devices equipped with Wi-Fi communication capacity (PDAs,

PCs, etc.)

2 Use the Wi-Fi connection function supported by the device to connect to the printer.

NOTE

Please refer to the conguration manual for details.

8. Hexadecimal Dump

This feature allows experienced users to see exactly what data is coming to the

printer. This can be useful in nding software problems.

When you go into the hex dump function, the printer prints all commands and other

data in hexadecimal format along with a guide section to help you nd specic com-

mands.

To use the hex dump feature, follow these steps

1 Please turn printer o.

2 Please turn printer on while press down “FEED” button.

3 Press the FEED button three times when the Self Test printed.

4 Now printer had entered into Hexa dump mode.

5 Run any software program that sends data to the printer. The printer prints

”Hexadecimal printing mode…” and then all the codes it receives in a two-column

format. The rst column contains the hecadecimal codes and the second column

gives the ASCII characters that correspond to the codes.

Hecadecimal Dump

1B 21 00 1B 26 02 40 40 .!..& . @ @

1B 25 01 1B 63 34 00 1B .%..c4 ..

41 42 43 44 45 46 47 48 ABCDEFGH

A period (.) is printed for each code that has no ASCII equivalent.

6 Turn o the printer.

7 Turn on the printer.

22

21 22

21

11. Linerless Printer

11-1. Linerless Printer Cleaning

Paper dust or impurities inside the printer may cause printing problems. Please clean as below.

1 Open the printer cover and clean the paper PASS part.

2 Remove the paper if it is jammed.

3 Remove impurities from cutter blade with cleaning pen or alcohol.

4 Wipe the printer head and roller with cleaning pen.

5 Wipe the paper detection sensor with a cotton swab or cloth.

6 When using linerless paper, please perform cleaning before using 30 Rolls or within a week.

NOTE

If the adhesive builds up due to poor cleaning, printing problems may occur.

11-2. Recommended Paper

MAX International Converters, Inc. MAXStick Products Ltd(USA)

WARNING

We are not responsible for any paper use issues other than recommended paper,

which may result in poor print quality or damage to the product.

10. Printer Cleaning

If the interior of the printer is dusty, printing quality can be lowered.

In this case, follow the instructions below to clean the printer.

NOTE

1 Make sure to turn the printer power o prior to cleaning

2 Regarding print head cleaning, as the print head is very hot during printing, turn o the

printer power and wait approximately 10 minute before start.

3 When cleaning the print head, take care not to touch the heated part of the print head. The

print head subject to be damaged by static electricity.

4 Take care not to allow the print head to become scratched and /or damaged in any way.

1 Use an applicator swab moistened with an alcohol solution to clean the print head and

remove any dusts.

2 Once the cleaning is completed, insert paper roll into the printer few minutes later and close

the printer cover.

3 In case of using sticky paper, it is recommended to clean it at least once a week or

once after printing on 30 rolls.

Preventing Overheating

To prevent the motor from overheating, continuous operation of the printer should be 1.5 m

or less in print length. Set the pause time for 30 seconds or more than it.

24

23 24

23

Interface Standard USB(B type)

Option Serial(RS-232C), Parallel(IEEE1284),

Ethernet, Wi-Fi(802.11 a/b/g/n),

Bluetooth Ver2.1(Movon,iOS)

Bluetooth Ver 4.2(Movon,iOS)

Cash drawer 2 circuits(24V, 1A Max.)

Reliability MCBF 60 million lines

TPH Life 160Km / Linerless - 100km

Cutter Type Guillotine

Life TE202Ⅱ- 1,800,000 cuts

TE203 - 1,500,000 cuts

Linerless - 1,000,000 cuts

Paper

Thickness 0.06 ~ 0.09mm

Power AC 100 ~ 240Vac 50/60 Hz

DC 24Vdc / 1.75A

Size 1562 × 204 × 150 [W x D x H (mm)]

Weight 1.7kg

Temperature Operation 0 ~ 45℃ (Linerless : 0 ~ 30℃)

Storage -20 ~ 60℃

Humidity Operation 35 ~ 80%

Storage 10 ~ 90%

Printing Method Direct Thermal

Printing Speed TE202Ⅱ- Max. 220 mm/sec

TE203 - Max. 300 mm/sec

Linerless - Max. 160mm/sec

Resolution 180 DPI / 203 DPI (Optional)

Dot Pitch

0.141mm x 0.141mm / 0.125mm x 0.125mm

Printing Width

Max. 72mm / 80mm

Number of print columns

Font A - 42 columns / Font B - 56 columns

Barcode 1D EAN-8, EAN-13, Code 39, Code 93, Code 128,

ITF, UPC-A, UPC-E, Codabar

2D PDF 417, QR code, DATA MATRIX

Emulation ESC/POS Command compatible

Driver Windows Driver(XP ~, Server2003 ~),

Windows CE & Mobile Driver(CE 4.2 ~, Mobile

5.0 ~), Linux Driver, Mac Driver, OPOS Driver,

JavaPOS Driver, iOS SDK, Android(6.0 ~) SDK,

Windows SDK, Windows CE SDK Linux SDK

Paper Paper type Thermal paper / Linerless (Optional)

Width 50 ~ 82.5

Thickness 0.06 ~ 0.09mm

Roll Max

Diameter Max. 80mm

Roll Core 12.5mm ± 0.5mm

Sensor Standard Paper End, Paper Low, Cover Open

Option Black Mark

12 Specications

26

25 26

25

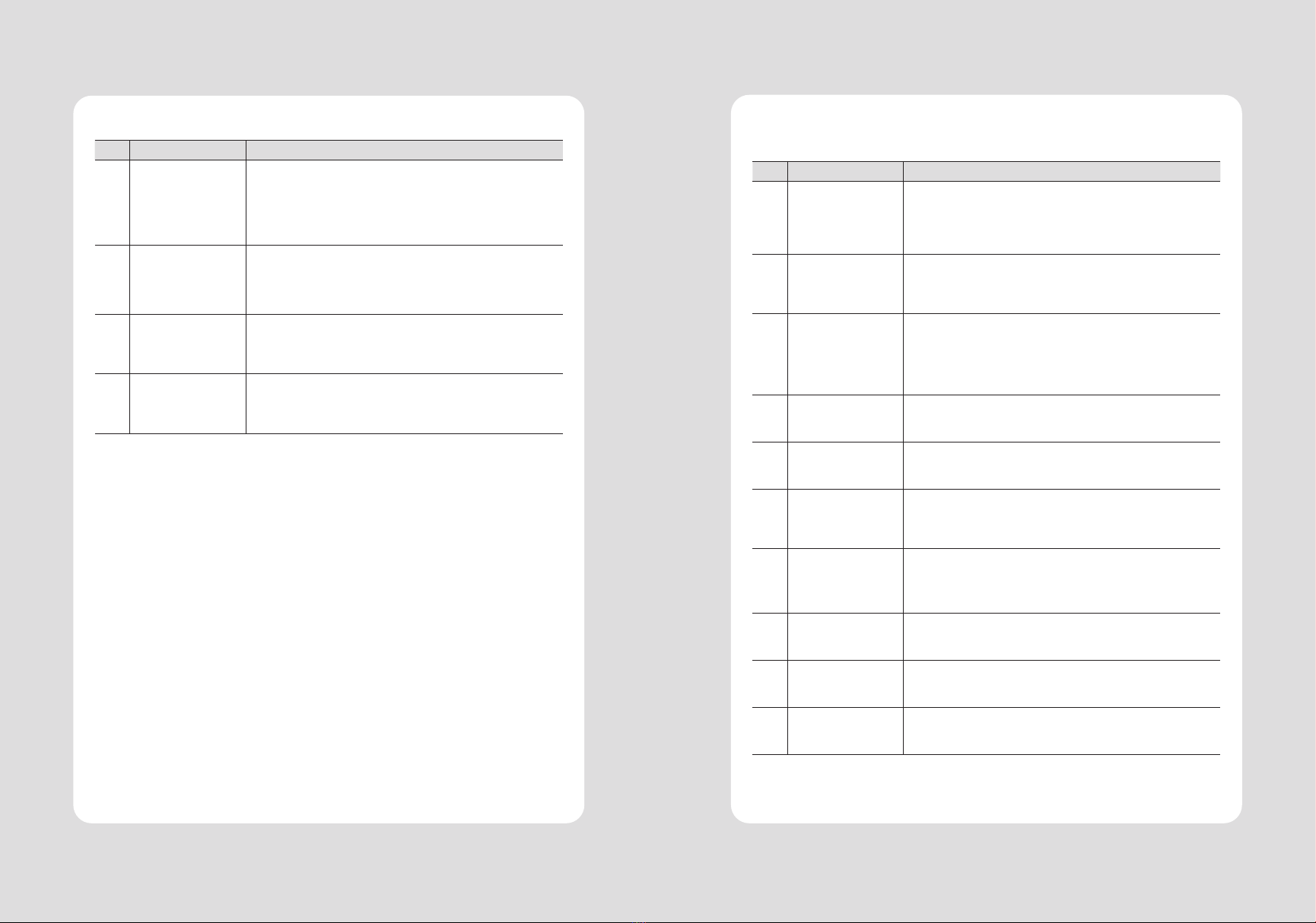

No. Command Function REMARKS

40 ESC t Select character code table

41 ESC { Turn upside-down printing mode on/off

42 FS p Print NV bit image

43 FS q Define NV bit image

44 GS ! Select character size

45 GS $ Set absolute vertical print position in page mode

46 GS * Define downloaded bit image

47 GS / Print downloaded bit image

48 GS B Turn white/black reverse printing mode on/off

49 GS H Select printing position of HRI characters

50 GS I Transmit printer ID

51 GS L Set left margin

52 GS P Set horizontal and vertical motion units

53 GS V Select cut mode and cut paper

54 GS W Set printing area width

55 GS \ Set relative vertical print position in page mode

56 GS a Enable/disable Automatic Status Back(ASB)

57 GS f Select font for HRI characters

58 GS h Set bar code height

59 GS k Print bar code

60 GS r Transmit status

61 GS v 0 Print raster bit image

62 GS w Set bar code width

< Add >

1 ESC i Full cut

2 ESC m Partial cut

3 FS ! Set print mode(s) for Kanji characters

4 FS & Select Kanji character mode

5 FS - Turn underline mode on/off for Kanji character

6 FS . Cancel Kanji character mode

7 FS 2 c1 d1…dk Define user-defined Kanji characters

8 FS C Select Kanji character code system

9 FS S 1 2 Set Kanji character spacing

10 FS W Turn quadruple-size mode on/off for Kanji character

No. Command Function REMARKS

1 HT Horizontal tab

2 LF Print and line feed

3 CR Print and carriage return

4 FF Print and return to standard mode(in page mode)

5 CAN Cancel print data in page mode

6 DLE EOT Real-time status transmission

7 DLE ENQ Real-time request to printer

8 DLE DC4 Generate pulse at real-time

9 ESC FF Print data in page mode

10 ESC SP Set right-side character spacing

11 ESC ! Select print mode(s)

12 ESC $ Set absolute print position

13 ESC % Select/cancel user-dened character set

14 ESC & Dene user-dened characters

15 ESC * Set bit-image mode

16 ESC - Turn underline mode on/o

17 ESC 2 Select default line spacing

18 ESC 3 Set line spacing

19 ESC = Select peripheral device

20 ESC ? Cancel user-dened characters

21 ESC @ Initialize printer

22 ESC D Set horizontal tab positions

23 ESC E Turn emphasized mode on/o

24 ESC G Turn double-strike mode on/o

25 ESC J Print and feed paper using minimum units

26 ESC L Select page mode

27 ESC M Select character font

28 ESC R Select an international character set

29 ESC S Select standard mode

30 ESC T Select print direction in page mode

31 ESC V Turn 90° clockwise rotation mode on/o

32 ESC W Set printing area in page mode

33 ESC \Set relative print position

34 ESC a Select justication

35 ESC c 3 Select paper sensor(s) to output paper-end

signals

36 ESC c 4 Select paper sensor(s) to stop printing

37 ESC c 5 Enable/disable panel buttons

38 ESC d Print and feed paper n lines

39 ESC p General pulse

13. Command List

28

27 28

27

15. S/W

We provides SDK, Driver, etc. as follows to respond to various S/W usage environments.

You can download this S/W from the homepage.

No. Name Description

1Windows Driver

This is an install program used to print a POS printer in Windows OS.

2 Linux Driver

This is the Cups Driver used to print a Thermal printer in the Linux

environment.

3 OPOS Driver

This is a driver that controls POS printers using the OPOS stan-

dard.

It can be used after initial setting(POS Printer&Cash Drawer) us-

ing the setting tool.

4 JavaPOS Driver The JavaPOS driver is an interface standard for POS software

written in Java.

5Mac Driver This is the Cups Driver used to print a Thermal printer in the Mac

OS environment.

6

Android Plugin

(Sewoo Print

Service Plugin)

This is a print service plug-in that allows you to print documents,

images, and web pages without installing additional apps.

7Windows SDK

This is library for communication and data output with Thermal

printer in Windows OS.

Can be used through direct communication and driver.

8Android SDK This is library for communication and data output with Thermal

printers in Android OS.

9iOS SDK This is library for communication and data output with Thermal

printers in iOS.

10 Linux SDK This is library for communication and data output with Thermal

printers in Linux.

The following utilities and concerned manual can be found on the CD or homepage.

No. Name Description

1Memory Saver

This is a utility that allows you to set printers by

interface.

Detailed settings such as Wi-Fi, Ethernet, and COM ports can be

congured.

2 NV Logo Upload

With NV Logo Upload running on Windows OS, you can upload and

remove the bmp le as Logo in the printer’s ash memory, and print

test is possible.

3 Download Tool

(F/W)

Printer F/W and Font Download are available, and BT, Wi-Fi mod-

ule F/W Download is supported as an option.

4 Android Utility

(Sewoo M_Utility)

It is a utility app that prints text, barcodes, images, etc. through

Bluetooth and Wi-Fi communication, and able to printer settings.

14. Utilities

Table of contents

Other SEWOO Printer manuals

SEWOO

SEWOO SLK-D10 User manual

SEWOO

SEWOO SLK-T12EB User manual

SEWOO

SEWOO LK-T41 User manual

SEWOO

SEWOO LK-P300 User manual

SEWOO

SEWOO LK-P41B User manual

SEWOO

SEWOO STL202II User manual

SEWOO

SEWOO LK-P43 User manual

SEWOO

SEWOO SLK-TL12X Series User manual

SEWOO

SEWOO LK-T200 User manual

SEWOO

SEWOO SLK-T42 User manual

SEWOO

SEWOO SLK-TL100 User manual

SEWOO

SEWOO LK-P11B User manual

SEWOO

SEWOO WTP-150 User manual

SEWOO

SEWOO SLK-TS400 User manual

SEWOO

SEWOO SLK-TE25 User manual

SEWOO

SEWOO SLK-TL100 User manual

SEWOO

SEWOO LK-P11 Installation instructions

SEWOO

SEWOO LK-P12B User manual

SEWOO

SEWOO LK-P30W User manual

SEWOO

SEWOO LK-P30IIW User manual