860 Series 2WD/4WD, Model - 8560

General Construction

The transmission case, clutch housing, engine and

front axle are bolted together to form a rigid unit.

Engine

This tractor is fitted with fuel-efficient US EPA certified

Mahindra-NE483 TCI engine. These are turbocharged,

Intercooled, 4 cylinder, direct injection type,

comprising of rotary fuel injection pump and comply

with US Tier-III norms.

Front Axle & Wheels (For 8560 2WD)

This is a square tube design, mounted on a central

pivot pin and is having adjustable wheel track.

The front wheels are mounted on taper roller bearings

housed in a hub which itself is mounted on the

steering knuckle. The tie rod is adjustable in four

inches increments in case of three piece front axle.

Front Axle & Wheels (For 8560 4WD)

Front Axle is live front axle, with planetary reduction.

The front wheels are directly mounted on the axle.

The front track is adjustable with adjustment provided

on the rims. The turning angles are all preset.

Power Steering

The Power Steering System consists of a Hydrostatic

Steering Unit (HSU), Hydraulic cylinder, Separate

Reservoir with Return line filter and Dipstick. Rear

section of tandem pump supplies oil to this system.

Clutch

These tractors are fitted with normally disengaged

PTO dual clutch assembly, having one each 12" driven

plate for transmission drive and an independent

Power Take-Off.

Transmission

The transmission is combination type wherein the

Speed and Forward-Reverse shifting is synchromesh

whereas Range is Constantmesh.

The speed gearshift arrangement is provided on RH

side of operator’s seat. Speed gears can be operated

in 4 modes.

The range gearshift arrangement is also provided on

RH side of operator’s seat thus providing more leg-

room and comfort of operation to the operator. The

Range gears can be operated in 3 modes Viz. High,

Medium and Low.

A Forward-Reverse shuttle is provided under the

steering wheel on (LH side) the tractor. This enables to

change the direction of tractor from forward to

reverse (and vice versa) in any of the pre-selected gear

combination. This feature is helpful in application like

loader, dozer, leveler etc.

GeneralDescription

Use of Range and speed shift with F-R Shuttle shift

arrangement enables the transmission to give

12 forward & 12 Reverse speeds.

Rear Axle & Wheels

The rear axle is mounted on bearings and is enclosed

in a removable housing which is bolted to the

transmission case. The rim & disc, fitted with rear

tires, are bolted to the outer flange of rear axle. The

Rear track adjustment is provided on the rims.

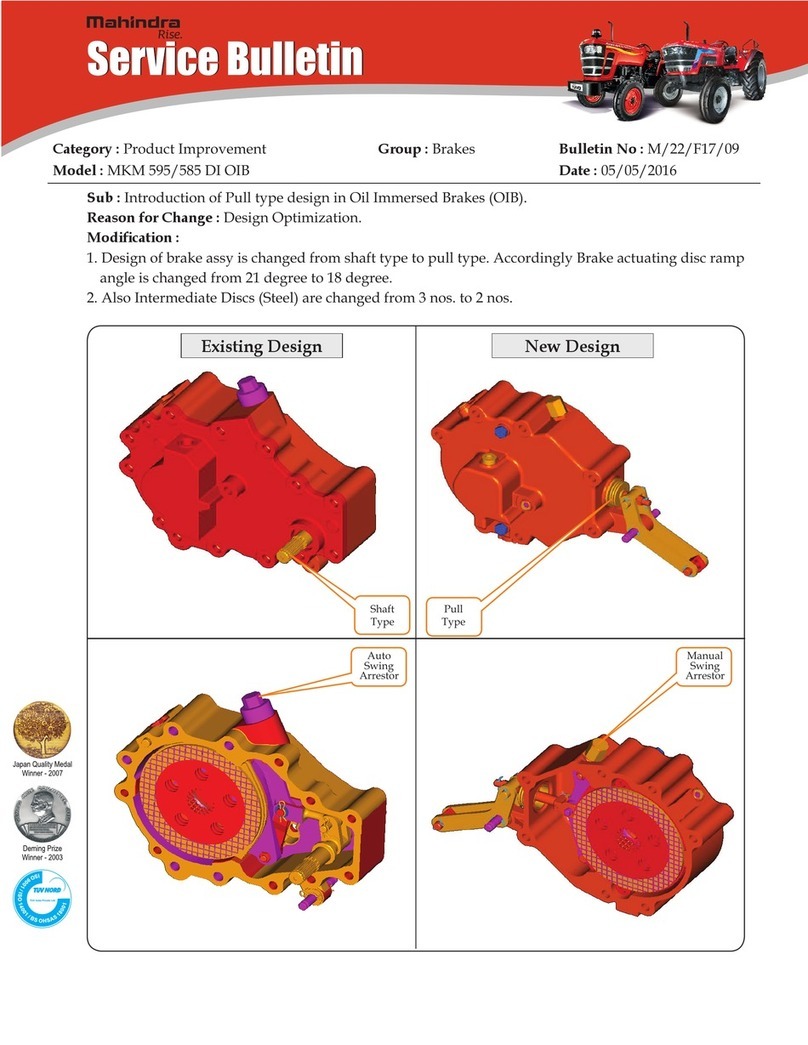

Oil Immersed Disc Brakes

These are oil-immersed brakes with five discs on

either side of tractor. The actuating disc is centrally

located between two pairs of brake discs. The two

drive plates are sandwiched between two pairs. Entire

brake assembly is housed in the brake housing which

is an integral part of transmission housing. Brake

pedal and linkages actuate brake.

A parking brake lever is fitted in front of operator’s

seat.

Hydraulic System

The tractor is fitted with fully “live” Hydraulic System.

Using a pump driven directly from the Engine. It is

able to operate the three-point linkage and auxiliary

valve entirely independent of any clutch movement

when changing gear or operating the power take-off.

The Oil reservoir is common with that of transmission.

Three Point Linkages

Three Point Linkage is suitable for category 2 type

implements. For ease of implement attachment,

a sliding mechanism is provided in the lower links.

Electrical System

A 12 volt lead acid battery is used to crank the engine

with the starter motor. The electrical system is

comprised of the head lamp, scuttle lamp, side

indicator lamps, plow lamp, brake light, parking

lamp, instrument cluster, alternator and fuse box and

relays.

Safety

PTO and Transmission neutral switch are a standard

feature

Sheet Metal

Hood, Scuttle, side panels, front grille & panel,

fenders, bracketaries, including platform are

constructed of sheet metal. After undergoing through

surface preparation, it is first primed & then painted.