|

|

Ma ntenance and Inspect on

9. Maintenance and Inspection

WARNING - The equipment must be inspecte

accor ing to the requirements of this section. Failure

to properly inspect the equipment coul lea to

severe injury or eath. The equipment must be

remove from service an inspecte imme iately if it

is subjecte to an abnormal loa or a shock loa . If

any irregularities or problems are etecte uring an

inspection, the equipment must be remove from

service imme iately an repaire . Contact the

manufacturer at the numbers an a ress printe on

the back cover of this manual.

9. Inspection

The owner must inspect, or appoint a knowle geable

person to inspect the unit for signs of corrosion an / or

excessive wear. Visual inspection shoul be ma e

before each use of the unit, checking for abnormal

con itions. Regular inspections shoul be ma e weekly

for aily use an monthly for intermittent use. Each unit

must be inspecte imme iately if subjecte to an

abnormal loa or shock. Any unit which appears to be

amage in any way, is foun to be ba ly worn, or

operates abnormally shall be remove from service until

necessary repairs are ma e.

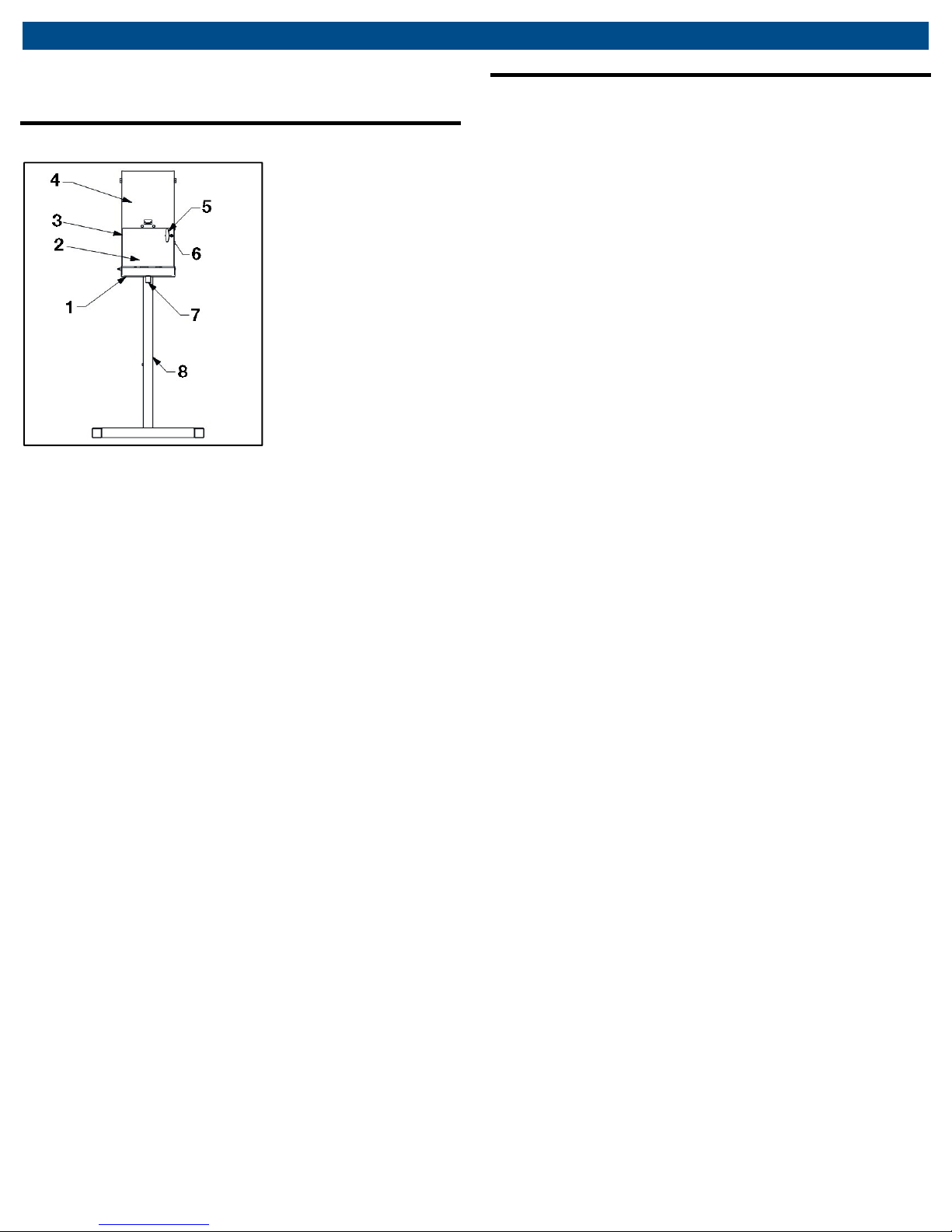

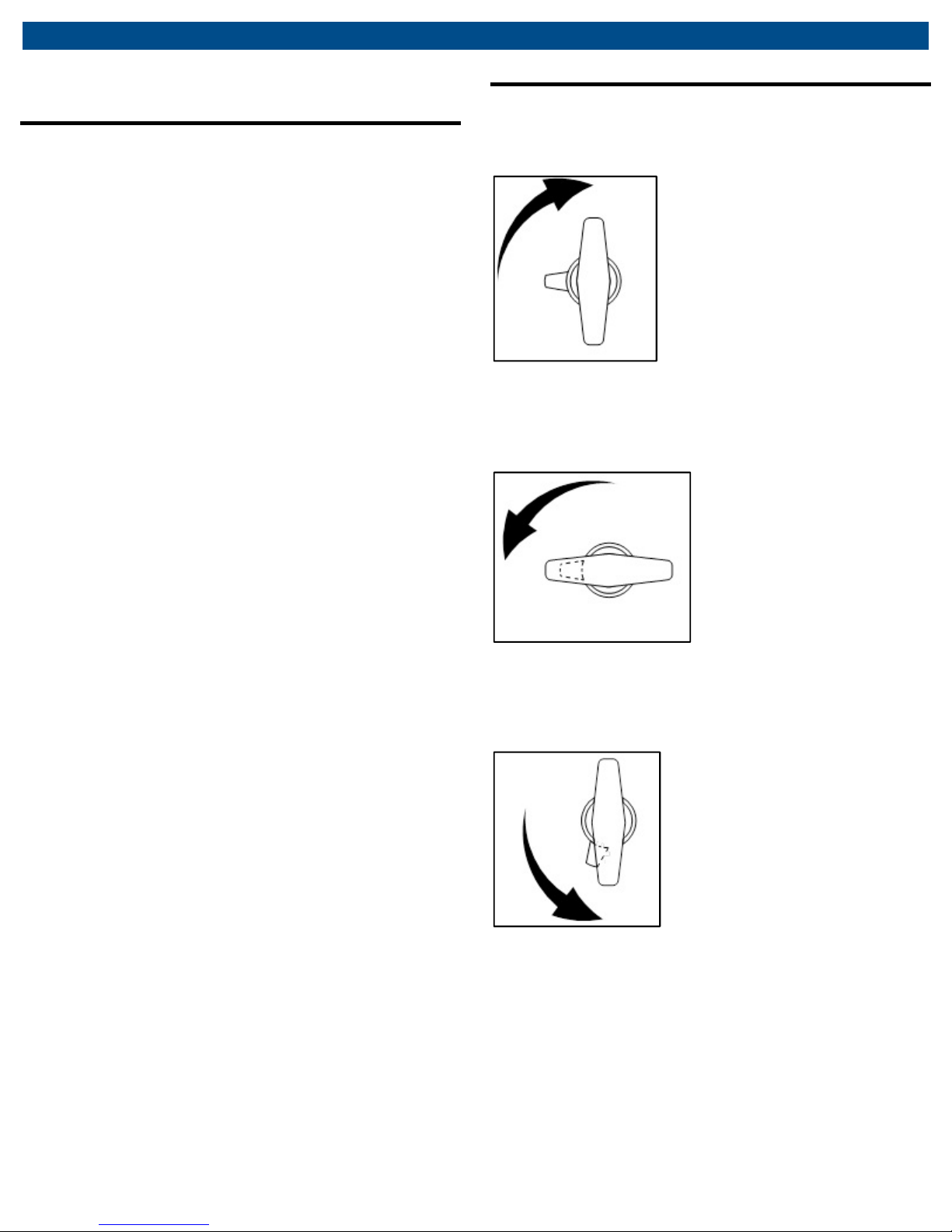

Inspect the oor for closure an oor han le latching

operation. The oor shoul close easily an the oor

han le shoul loosely latch with a 90- egree rotation

of the oor han le. Further 90- egree rotation of the

han le shoul clamp the oor shut an actuate the

control valve. There shoul be the soun of air

flowing for up to 45 secon s until the ram is fully

lowere an the air pressure in the ram cylin er

equalizes with the air supply.

After the air stops flowing, check the unit for

excessive leaks. An excessive leak is a leak which

can be hear an which egra es the performance

of the unit. Minor leaks o not a versely affect the

operation of the unit.

Unlatch the oor an the air shoul exhaust from the

ram cylin er. The oor shoul not open until the ram

has returne to its fully raise position

(approximately 10 secon s).

Inspect crushing chamber for amage or worn parts.

If any irregularities or problems are etecte uring

an inspection, the unit must be remove from service

imme iately an repaire . Contact the manufacturer

using the contact information on the back cover of

this manual.

9.2 Maintenance instructions

WARNING - All inspection an maintenance proce ures

must be performe after the equipment has been remove

from service. Failure to o this may result in personal injury

an /or property amage.

All warning an capacity labels shoul be rea able

an complete. Wash external surfaces of jack, labels,

an ecals with a mil soap solution.

Lubricate all rotating an sli ing portions of the jack

monthly.

9.3 Control valve actuation adjustment

Note: The setscrew on the oor that actuates the

control valve an the pawl on the oor han le latch

are a juste at the factory an shoul never nee

a justment.

1. Make sure the two screws securing the control valve

on the right han si e of the unit are tight. Make sure

the two screws securing the han le latch to the oor

are tight an the two jam nuts securing the latch pawl

to the stem are tight.

2. Loosen the jam nut securing the set screw on the

oor an back the setscrew out. Close oor an turn

oor han le fully clockwise to soli ly latch the oor.

3. Using a hex wrench, slowly tighten the setscrew until

the top platen lowers an there is no air leakage

etecte aroun the spool of the control valve.

Tighten the setscrew 1/2 turn further an secure the

setscrew with the jam nut.

4. Rotate the latch han le 1/4 turn counterclockwise.

The air shoul exhaust an the ram shoul retract, but

the pawl shoul remain loosely engage with the oor

close .

5. Rotate the latch fully counterclockwise an the oor

shoul open. Repeat steps 2 through 5 if the oor

oes not operate correctly.