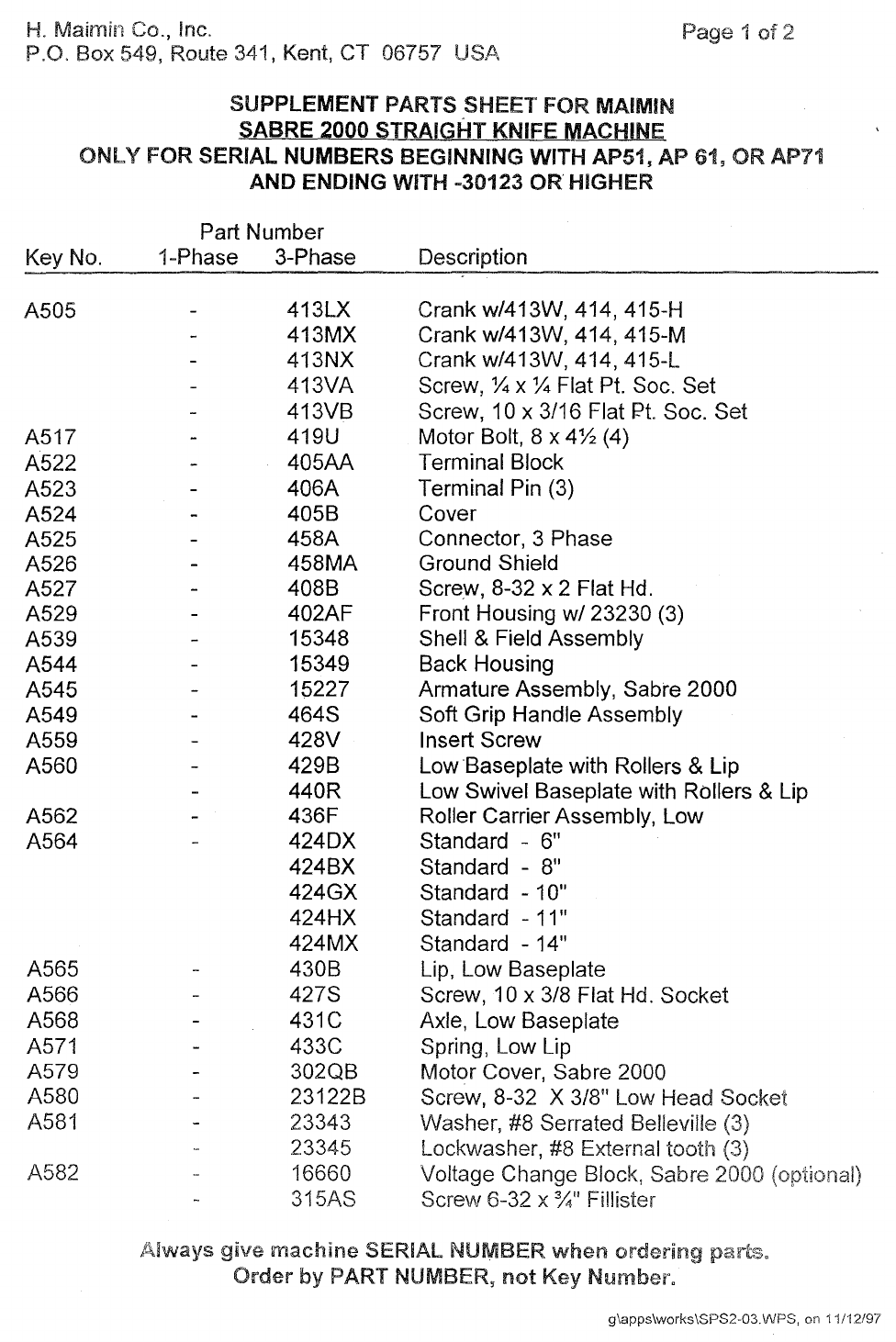

PARTS'

LIST

PART NO. PART NO.

KEY SABRE SABRE DESCRIPTION KEY SABRE SABRE DESCRIPTION

NO. 2000 3000 NO. 2000 3000

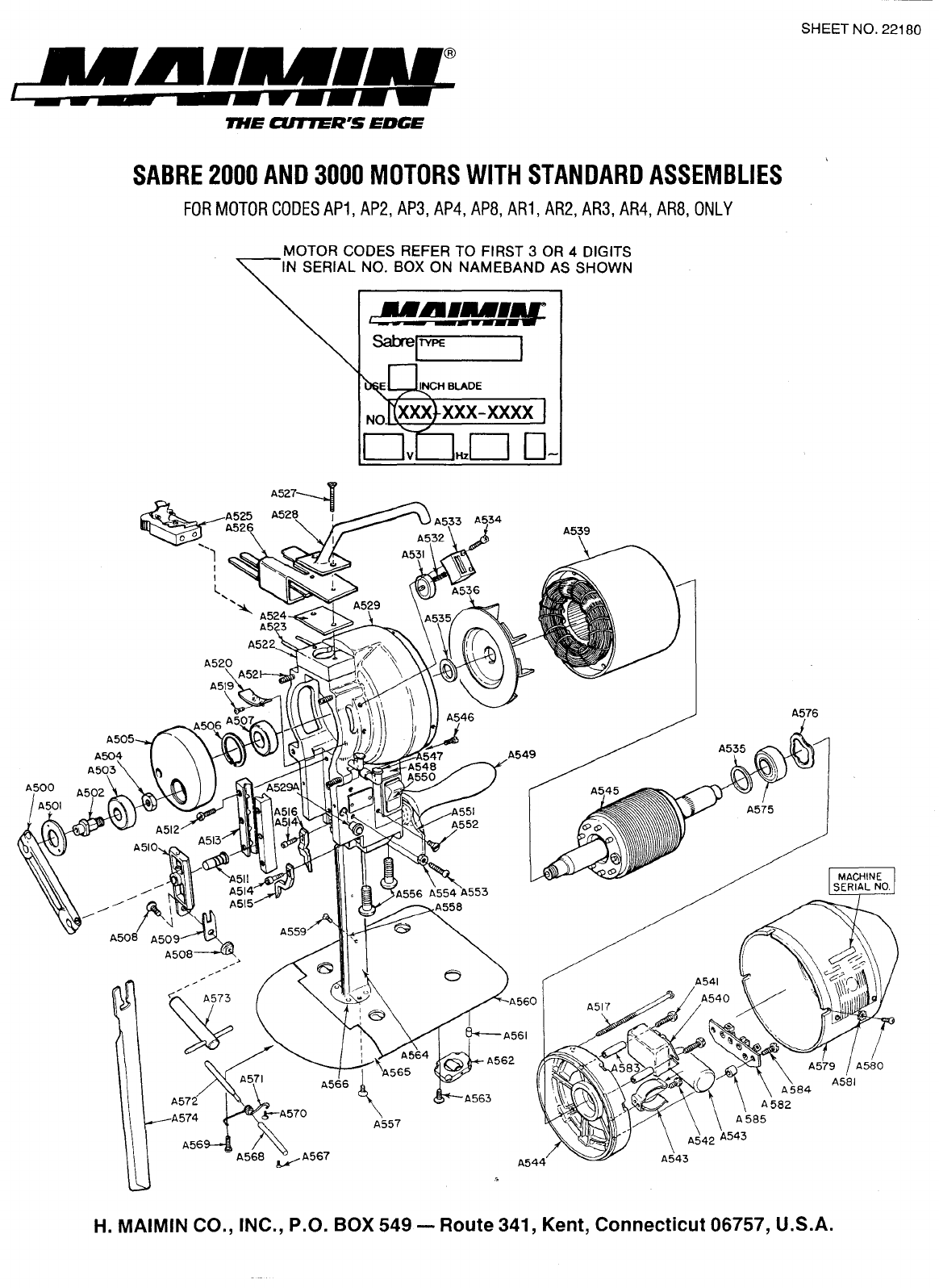

A500 412A 412A Connecting Rod - H 15282 Armature Assembly, Sabre 3000

412B 412B Connecting Rod - M A546 441S 441S Screw, 6 x

o/,

6 Fillister Hd.

(2)

412C 412C Connecting Rod - L A547 402BD 402BD Oil Cup

A501 413W 413W Bearing Lock 402B 402B Oil Cup Assemblywith Tube

A502 415 415 Crank Pin A548 466G 466G Cover, Switch Box

A503 414 414 Crank Bearing A549 464P 464P Contoured Handle w/Bushing

A504 415N 415N Crank Nut A550 443 443 Switch

A505 413BX 413BX Crank w/413W, 414, 415-H A551 464R 464R Shield

413CX 413CX Crankw/413W, 414, 415-M A552 818S 818S Screw, 6 x

V4

Flat Hd.

413DX 413DX Crankw/413W, 414, 415-L A553 410 410 Screw, 8 x

Y2

Fillister Hd.

(2)

A506 404E 404E Retaining Ring A554 410N 410N Nut

(2)

A507 403 403 Bearing #203 A556 425A 425A

Bolt,%

x

3/.s

Button Hd.

(3)

A508 416 416 Knife Bolt & Nut A557 427S 427S Screw, 10 x

%Flat

Hd. Soc.

(6)

A509 411A 411A T-Siot Lock A558 428B 428B Insertfor

Standard-

8"

A510

411

411

Crosshead w/411 P 428D

4280

Insertfor

Standard-

6"

A511 411P 411P Wrist Pin 428G 428G Insertfor Standard - 1

0"

A512 409A 409A Screw, 8 x 3/4 Fillister Hd.

(6)

428H 428H Insert for

Standard-

11"

A513 409C 409C Gibbs, pair 428M 428M Insert for

Standard-

14"

A514 23226 23226 Screw, 6 x

'14

Socket Hd.

(2)

A559 428T 428T Insert Screw

A515 23151 23151 Cam, Right A560 429C 429C Baseplate with Rollers & Lip

A516 23152 23152 Cam, Left 440L 440L Swivel Baseplate with Rollers & Lip

A517 419U MotorBolt, 8-32 x

4112

Hex Washer A561 436K 436K Rubber Cushion

Hd.(4) A562 436 436 RollerCarrier Assembly

419F MotorBolt, 8-32 x

43/4

HexWasher 440M 440M Swivel RollerAssembly (Rear)

Hd.

(4)

440J

440J Swivel Adaptor Ring

A519 802S 802S Screw, 6 x 3A6 Binding Hd.

(2)

A563 436S 436S Screw, 10 x

%2M

Hd.

A520 402L 402L Oil Guard A564 424BS 424BS Standard -

8"

A521 23230 23230 Screw, 10 x % Flat Pt. Soc. Set

(3)

4240S

4240S

Standard-

6"

A522 405 405 Terminal Block with Pins 424GS 424GS Standard

-10"

A523 406 406 Terminal Pin

(2)

424HS 424HS Standard -

11

"

A524 405PE 405PE Fibre Cover 424MS 424MS Standard

-14"

A525 458B 458B Current Connector A565 430 430 Lip

A526 458K 458K Ground Shield A566 426A 426A Throat

Plate-

6",

8"

A527 408 408 Screw, 8 x 1% Flat Hd. 426B 426B

ThroatPiate-10",

11",

14"

A528 407D 407D Top Handle 426C 426C Throat Plate, Wide

Slot-

6",

8",

1

0"

A529 402AB 402AB Front Housing w/23230

(3)

426E 426E V Throat

Plate-

6",

8"

A529A 402BG 402BG Tapered

Plu~

#7-S 426F 426F VThroat Plate

-10",

11

",

14"

A531

468J 468J Thumbwhee w/Shaft A567 436S 436S Screw, 10 x %2M Hd.

A532 468C 468C Spring A568 431B 431B Shaft, Short

A533

4680

4680

Thumbwheel Support A569 802S 802S Screw, 6 x 3

/,

6 Binding Hd.

468A 468A Thumbwheel Assembly A570 802S 802S Screw, 6 x 3;j6 Binding Hd.

A534 468S 468S Screw, 6 x

%Socket

Hd.

(2)

A571 433A 433A Spring, Lip

A535 497P 497P Support Washer A572 431A 431A Shaft, Long

A536 400K 400K Fan A573 457 457 Knife Key

A539 15260 Shell & Field Assembly, SABRE 2000 A574 Blade (see back cover)

15283 Shell & Field Assembly, SABRE 3000 A575 403 403 Bearing #203

A540 365A Starting Switch, SABRE 2000 A576 15195 15195

Loadi"8

Spri~

365J Starting Switch, SABRE 3000 A579 302QB Motor over, ABRE 2000

A541 15264 15264 Screw, 8-32 x

1'14

Phillips Pan Hd.

(2)

302QM Motor Cover, SABRE 3000

15288 15288

Washer%

x .175 x .035

(2)

A580 23122 23122 Screw, 6 x

'14

Button Hd.

(3)

A542 15266 15266 Screw, 8-32 x

%Phillips

Pan Hd. A581 309F 309F Lockwasher, #6

(3)

A543 15262 15262 Capacitor Clamp A582 483G 483G Terminal Strip

15079 Capacitor

161

mfd -Sabre 2000 A583 15265 15265 Spacer, Starting Switch

(2)

15076 Capacitor 270 mfd

-Sabre

3000 A584 15267 15267 Screw, 8-32 x

%Phillips

Pan Hd.

(2)

A544 15261

15261

Back Housing A585 15268 15268 Spacer, Terminal Strip

(2)

A545 15277 Armature Assembly, Sabre 2000

Always Give Machine SERIAL NUMBER When Ordering Parts.

Order

By

PART

NUMBER-

Not Key Number

H.

MAIMIN

CO.,

INC.

P.O. BOX

549-

ROUTE 341, KENT, CONNECTICUT 06757, U.S.A.

PHONE: (203) 927-4601 FAX: (203) 927-4703

Printed

in

U.S.A. MPS2, 3/0991

From the library of: Superior Sewing Machine & Supply LLC