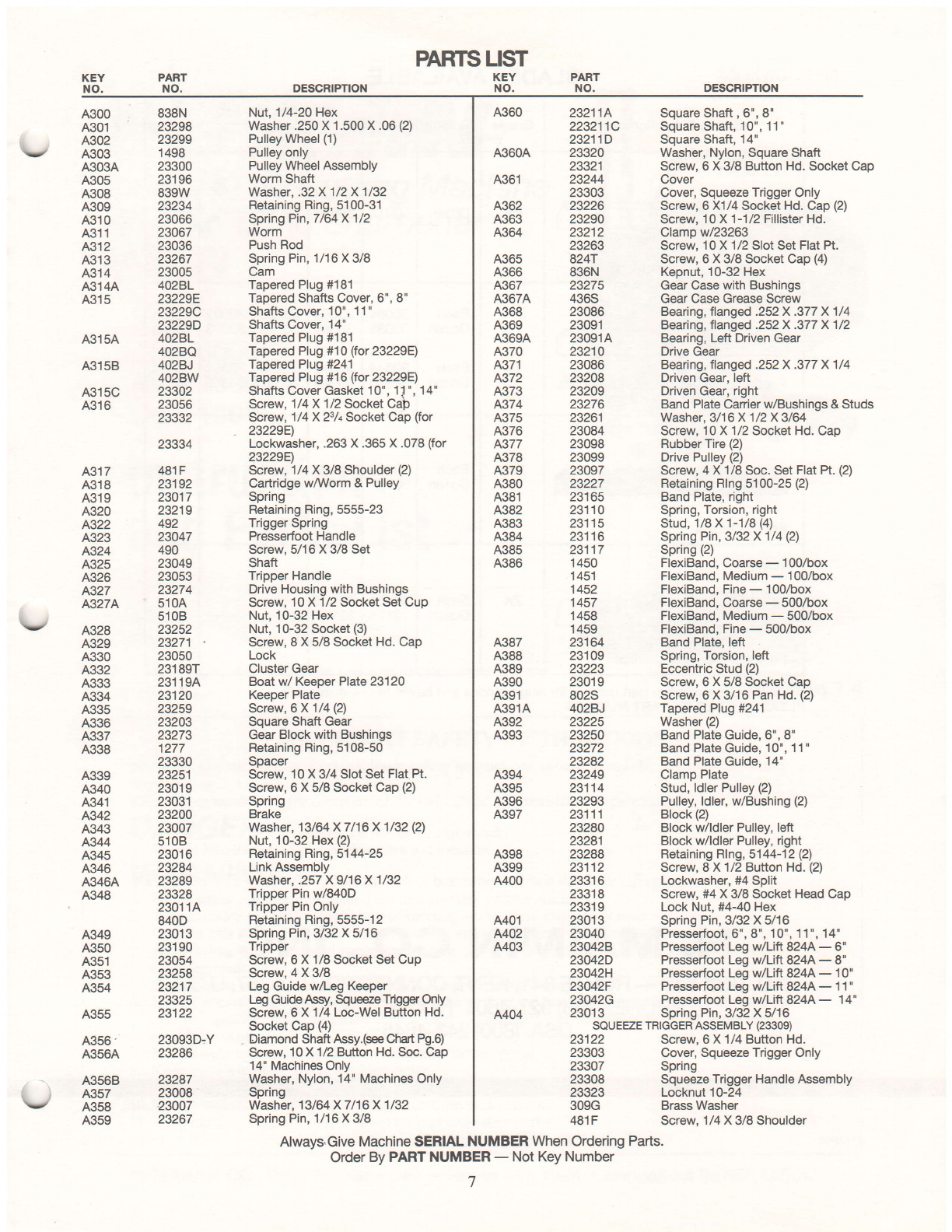

KEY PART

NO. NO. DESCRIPTION

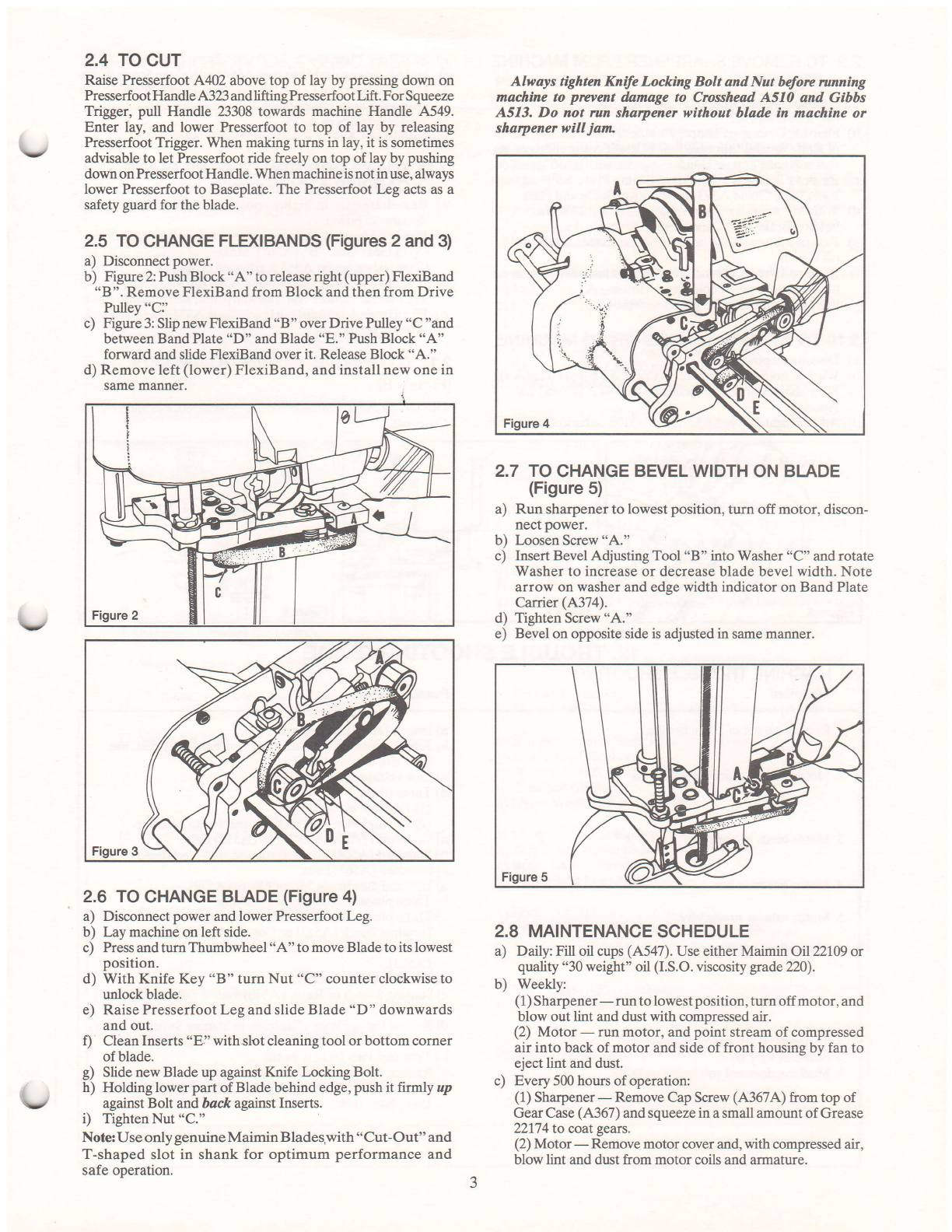

Nut, 1/4-20 Hex

Washer .250 X 1.500 X .06 (2)

Pulley Wheel (1)

Pulley only

Pulley Wheel Assembly

Worm Shaft

Washer, .32X1/2X1/32

Retaining Ring, 51 00-31

Spring Pin,7/64X1/2

Worm

Push Rod

Spring Pin, 1/16X3/8

Cam

Tapered Plug #181

Tapered Shafts Cover, 6", 8"

ShaftsCover,10',11"

Shafts Cover, 14"

Tapered Plug #181

Tapered Plug #10 (tor 23229fl

Tapered Plug#241

Tapered Plug #16 (tor 23229Q

Shafts Cover Gasket 1 0", 11',14'

Screw, 1/4 X 1/2 Socket Cap

Screw, 1/4 X 2314 Socket Cap (for

23229E)

Lockwasher, .263 X .365 X.078 (for

23229F.

Screw, 1/4 X 3/8 Shoulder (2)

Cartridge wAVorm & Pulley

Spring

Retaining Ring, 5555-23

Trigger Spring

Presserfoot Handle

Screw, 5/'16 X 3/8 Set

Shaft

Tripper Handle

Drive Housing with Bushings

Screw, 1 0 X 1/2 Socket Set Cup

Nut, 10-32 Hex

Nut, 10-32 Socket (3)

Screw, 8 X 5/8 Socket Hd. Cap

Lock

Cluster Gear

Boat w/ Keeoer Plate 23120

Keeper Plate

Screw, 6 X1/4 (2)

Square Shaft Gear

Gear Block with Bushings

Retaining Ring, 5108-50

Spacer

Screw, 10 X 3/4 Slot Set Flat Pt.

Screw, 6 X 5/8 Socket Cap (2)

Spring

Brake

Washer, 13/64 X 7/16 X 1 /32 (2\

Nut, 10-32 Hex (2)

Retaining Ring, 5144-25

Link Assembly

Washer, .257 X 9/16 X 1/32

Tripper Pin w/840D

Tripper Pin Only

Retaining Ring, 5555-12

Spring Pin, 3/32X5/16

Tripper

Screw, 6 X 1/8 Socket Set Cup

Screw, 4 X 3/8

Leg Guide w/Leg Keeper

l-eg Guide Assy, Squeeze Trigger orily

Screw, 6 X 1/4 Loc-Wel Button Hd.

Socket Cap (4)

. Diamond Shaft Assy.(seeOhatt Pg.6)

Screw, 10 X 1/2 Button Hd. Soc. Cap

14" Machines Only

Washer, Nylon, 14" Machines Only

Spring

Washer, 13/64 X 7/16X 1132

Spring Pin, 1116X3/8

PARTS UST

A360

PART

NO.

KEY

NO.

v

v

A300

A301

A302

A303

A3O3A

A305

A308

4309

A310

A31 1

^.312

A3't3

A314

A314A

4315

A315A

A3158

A315C

A316

4317

4318

4319

A320

4322

A323

4324

A325

A326

4327

A.3274

A328

4329

4330

A332

A333

A334

A335

A336

A337

4338

A339

A340

A341

4342

4343

4344

A345

A346

A346A

A348

4355

A356-

A3564

A356B

A357

A358

A359

838N

23298

23299

1 498

23300

231 96

839W

23234

23066

23067

23036

23267

23005

4O2BL

23229E

23229C

232290

4O2BL

4O2BQ

4O2BJ

4028W

23302

23056

23332

23334

481F

23192

23017

23219

492

23047

490

23049

23053

23274

51 0A

510B

23252

23271

23050

231897

231 1 9A

23120

23259

23203

23273

1277

23330

23251

23019

23031

23200

23007

5108

2301 6

23284

23289

23328

2301 1A

840D

2301 3

231 90

23054

23258

23217

23325

23122

23093D.Y

23286

23287

23008

23007

23267

A36OA

A361

A362

A363

A364

A365

A366

4367

A367A

A368

A369

A369A

4370

A371

4372

4373

4374

A375

A376

A377

A378

4379

A380

A381

A382

4383

A384

A385

A386

4387

A388

A389

A390

A391

A3914

A392

A393

A401

4402

A403

23212

23263

8247

836N

23275

436S

23086

23091

230914

23210

23276

23261

23084

23098

23099

23097

23227

231 65

23110

23115

23116

23117

1450

1451

1452

1457

1458

1459

23164

231 09

23223

23019

802S

4O2BJ

23225

23250

23272

23282

23249

23114

23293

23111

23280

23281

23288

23112

23316

23318

2331 I

2301 3

DESCRIPTION

23211A. Square Shaft , 6", 8"

223211C SquareShaft. 10".11"

23211D Square Shaft, 14"

23320 Washer, Nylon, Square Shaft

23321 Screw. 6 X 3/8 Button Hd. Socket Cao

23244 Cover

23303 Cover, Squeeze Trigger Only

23226 Screw, 6 X1l4 Socket Hd. Cap (2)

23290 Screw. 10 X1-1/2 Fillister Hd.

Clamo w/23263

Screw, 10 X 1/2 Slot Set Flat Pt.

Screw, 6 X 3/8 Socket Cap (4)

Kepnut, 10-32 Hex

Gear Case with Bushings

Gear Case Grease Screw

Bearing, flanged .252X .377 X1/4

Bearing, flanged .252X .377 X1/2

Bearing, Left Driven Gear

Drive Gear

23086 Bearing, flanged .252X .377 X1/4

23208 Driven Gear, left

23209 Driven Gear, right

A394

A395

A396

A397

A398

A399

A400

Band Plate Canier WBushings & Studs

Washer, 3/'16 X 1/2 X 3/64

Screw, 10 X 1/2 Socket Hd. Cap

Rubber Tire (2)

Drive Pulley (2)

Screw, 4 X 1/8 Soc. Set Flat Pt. (2)

Retaining Rlng 5100-25 (2)

Band Plate, right

Spring, Torsion, right

Stud, 1/8 X 1 -1l8 (4)

Spring Pin, 3/32 X 1 /4 (2)

Spring (2)

FlexiBand, Goarse - 100/box

FlexiBand, Medium -'l 00/box

FlexiBand, Fine - 100/box

FlexiBand. Coarse - 500/box

FlexiBand, Medium - 500/lcox

FlexiBand, Fine - 500/box

Band Plate, left

Spring, Torsion, left

Eccentric Stud (2)

Screw, 6 X 5/8 Socket Cap

Screw,6 X 3/16 Pan Hd. (2)

Tapered Plug #241

Washer (2)

Band Plate Guide, 6",8"

Band Plate Guide, 10", 't 1"

Band Plate Guide, 14"

Clamp Plate

Stud, ldler Pulley (2)

Pulley, ldler, w/Bushing (2)

Block (2)

Block w/ldler Pulley, left

Block w/ldler Pulley, right

Retaining Rlng, 51 44-1 2 (2)

Screw, 8 X 1/2 Button Hd. (2)

Lockwasher, #4 Split

Screw, #4 X 3/8 Socket Head Cap

Lock Nut, #4-40 Hex

Spring Pin, 3/32X5/16

A349

4350

A351

A353

A354

23040 Presserfoot, 6', 8", 1 0", 1',| ", 14"

230428 Presserfoot Leg wAift 824A - 6'

23042D Presserfoot Leg wAift 824A-8"

23042H Presserfoot Leg wAift 824A - 10'

23O42F Presserfoot Leg wAift 824A- 11'

23O42G Presserfoot Leg wAift 8244- 14"

23013 Spring Pin, 3/32X5/16

SQUEEZE TRTGGER ASSEMBLY (23309)

23122

23303

23307

23308

23323

309G

481 F

Screw, 6 X 1/4 Button Hd.

Cover, Squeeze Trigger Only

Spring

Squeeze Trigger Handle Assembly

Locknut 10-24

Brass Washer

Screw. 1/4 X 3/8 Shoulder

Always'Give Machine SERIAL NUMBER When Ordering Parts.

Order By PART NUMBER - Not Key Number