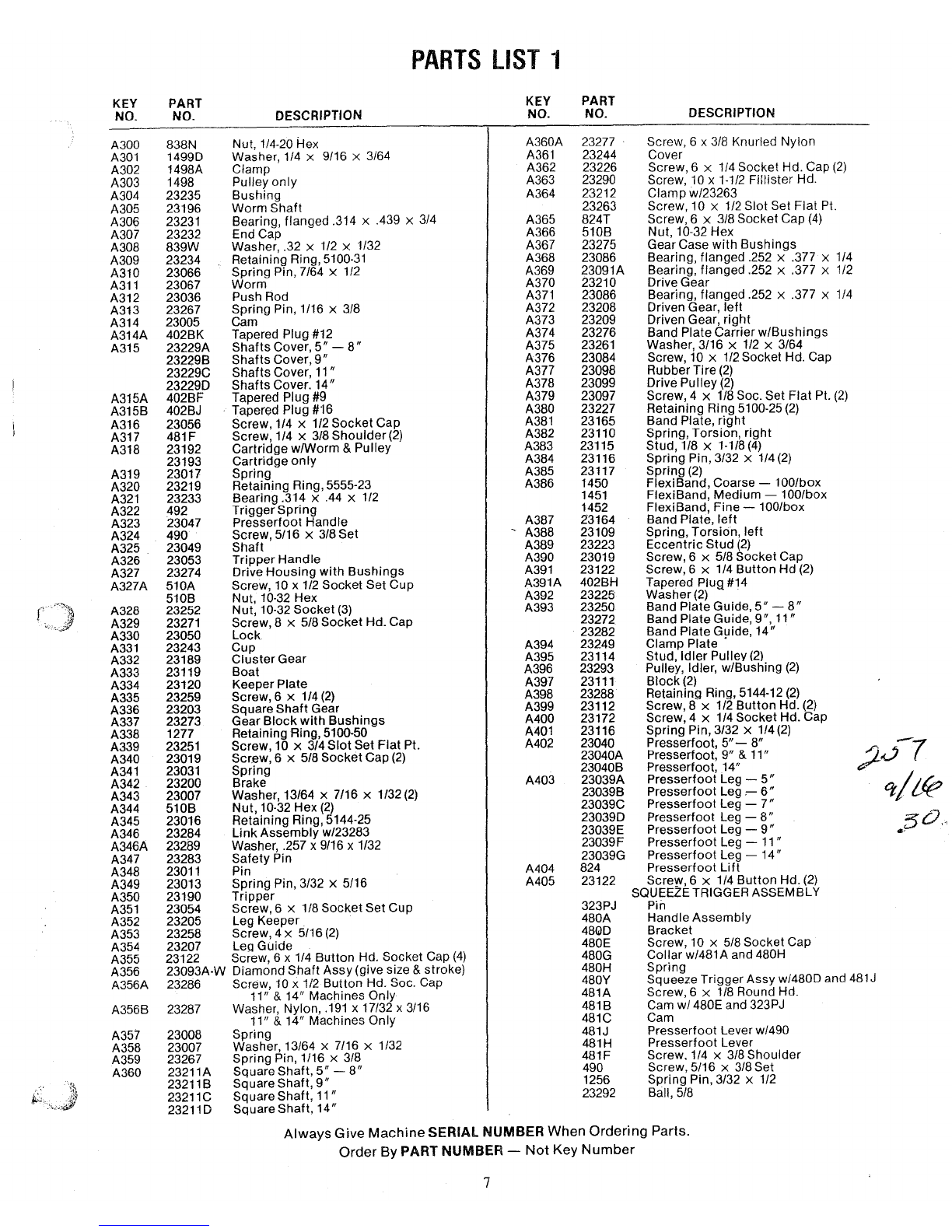

PARTS

LIST

1

KEY PART KEY PART

NO. NO. DESCRIPTION NO. NO. DESCRIPTION

A300 838N Nut, 1/4-20 Hex A360A 23277 Screw, 6 x 3/8 Knurled Nylon

A301

1499D Washer, 1/4 x 9/16 x 3/64

A361

23244 Cover

A302 1498A Clamp A362 23226 Screw, 6 x

1/4

Socket Hd. Cap

(2)

A303 1498 Pulley

only

A363 23290 Screw,

10

x 1·1/2 Fillister Hd.

A304 23235

Bushing

A364 23212 Clamp w/23263

A305 23196 Worm

Shaft

23263 Screw, 10 x

1/2

Slot

Set

Flat

Pt.

A306 23231 Bearing, flanged .314 x .439 x 3/4 A365 824T Screw, 6 x 3/8 Socket Cap

(4)

A307 23232 End Cap A366 510B Nut, 10-32 Hex

A308 839W Washer, .32 x

1/2

x 1/32 A367 23275 Gear Case

with

Bushings

A309 23234 Retaining Ring,

5100-31

A368 23086 Bearing, flanged .252 x .377 x 1/4

A310 23066 Spring Pin,

7164

x 1/2 A369 23091A Bearing, flanged .252 x .377 x 1/2

A311

23067

Worm

A370 23210 Drive Gear

A312 23036 Push Rod

A371

23086 Bearing, flanged .252 x .377 x

1/4

A313 23267 Spring Pin, 1/16 x 3/8 A372 23208 Driven Gear,

left

A314 23005 Cam A373 23209 Driven Gear, right

A314A 402BK Tapered Plug #12 A374 23276 Band Plate Carrier

w/Bushings

A315 23229A

Shafts

Cover,

5"

-

8"

A375 23261 Washer, 3/16 x

112

x 3/64

23229B

Shafts

Cover,

9"

A376 23084 Screw,

10

x

1/2

Socket Hd. Cap

23229C

Shafts

Cover,

11

" A377 23098 RubberTire

(2)

23229D

Shafts

Cover.

14"

A378 23099 Drive Pulley

(2)

A315A 402BF Tapered Plug #9 A379 23097 Screw, 4 x

118

Soc. Set

Flat

Pt.

(2)

A315B 402BJ Tapered Plug

#"16

A380 23227 Retaining Ring 5100-25

(2)

A316 23056 Screw, 1/4 x 1/2

Socket

Cap

A381

23165 Band Plate,

right

A317 481F Screw, 1/4 x 3/8

Shoulder

(2)

A382 23110 Spring, Torsion, right

A318 23192 Cartridge w/Worm &Pulley A383 23115 Stud,

118

X 1-1/8

(4)

23193 Cartridge

only

A384 23116 Spring Pin, 3/32 x 1/4

(2)

A319 23017 Spring A385 23117 Spring

(2)

A320 23219 Retaining Ring, 5555·23 A386 1450 FlexiBand,

Coarse-

100/box

A321

23233 Bearing .314 x .44 x 1/2

1451

FlexiBand,

Medium-

100/box

A322 492

Trigger

Spring

1452 FlexiBand,

Fine-

100/box

A323 23047 Presserfoot Handle A387 23164 Band Plate,

left

A324 490 Screw, 5/16 x 3/8 Set -A388 23109 Spring, Torsion,

left

A325 23049

Shaft

A389 23223

Eccentric

Stud

(2)

A326 23053 Tripper Handle A390 23019 Screw, 6 x 5/8 Socket Cap

A327 23274 Drive

Housing

with

Bushings

A391

23122 Screw, 6 x 1/4

Button

Hd

(2)

A327A 510A Screw, 10 x

1/2

Socket Set Cup A391A 402BH Tapered

Plug

#14

510B Nut, 10·32 Hex A392 23225 Washer(2)

r A328 23252 Nut, 10·32

Socket

(3)

A393 23250 Band PlateGuide,

5"-

8"

A329 23271 Screw, 8 x 5/8

Socket

Hd. Cap 23272 Band Plate Guide,

9",

11"

A330 23050 Lock 23282 Band Plate Guide,

14"

A331

23243

Cup

A394 23249 Clamp Plate ·

A332 23189

Cluster

Gear A395 23114 Stud,

Idler

Pulley

(2)

A333 23119 Boat A396 23293 Pulley, Idler, w/Bushing

(2)

A334 23120 Keeper Plate A397 23111

Block

(2)

A335 23259 Screw, 6 x 1/4

(2)

A398 23288 Retaining Ring, 5144-12

(2)

A336 23203 Square

Shaft

Gear A399 23112 Screw, 8 x 1/2

Button

Hd.

(2)

A337 23273 Gear

Block

with

Bushings

A400 23172 Screw, 4 x 1/4 Socket Hd. Cap

A338 1277 Retaining Ring, 5100-50

A401

23116 Spring Pin, 3/32 x 1/4

(2)

A339 23251 Screw,

10

x 3/4

Slot

Set Flat Pt. A402 23040 Presserfoot,

5"-

8"

;)J7

A340 23019 Screw, 6 x 5/8 Socket Cap

(2)

23040A Presserfoot,

9"

&

11

"

A341

23031 Spring 23040B Presserfoot, 14"

A342 23200 Brake A403 23039A Presserfoot Leg -

5"

ot/tfi?

A343 23007 Washer, 13/64 x 7/16 x 1/32

(2)

23039B Presserfoot Leg,.--

6"

A344 510B

Nut,

10·32 Hex

(2)

23039C Presserfoot Leg -

7"

A345 23016 Retaining Ring, 5144·25 23039D Presserfoot Leg -

8"

30·"

A346 23284

Link

Assembly

w/23283 23039E Presserfoot Leg -

9"

...

A346A 23289 Washer, .257 x

9116

x

1132

23039F Presserfoot Leg -

11

"

A347 23283 Safety Pin 23039G Presserfoot Leg -

14"

A348 23011 Pin A404

824

Presserfoot

Lift

A349 23013 Spring Pin, 3/32 x 5/16 A405 23122 Sere','/, 6 x

114

Button

Hd.

(2)

A350 23190 Tripper SQUEEZE TRIGGER ASSEMBLY

A351

23054 Screw, 6 x 1/8

Socket

Set Cup 323PJ Pin

A352 23205 Leg Keeper 480A Handle

Assembly

A353 23258 Screw, 4 x 5/16

(2)

48QD

Bracket

A354 23207 Leq Guide 480E Screw,

10

x 5/8 Socket Cap

A355 23122 Screw, 6 x

1/4

Button Hd. Socket Cap

(4)

480G Collar w/481A and 480H

A356 23093A·W Diamond

Shaft

Assy

(give size &stroke) 480H Spring

A356A 23286 Screw,

10

x

1/2

Button Hd. Soc. Cap 480Y Squeeze

Trigger

Assy w/4800 and

481

J

11" &14" Machines Only 481A Screw, 6 x

1/8

Round Hd.

A356B 23287 Washer, Nylon,

.191

x

17132

x 3/16 481B Cam

wl

480E and 323PJ

11" &14" Machines Only 481C Cam

A357 23008 Spring 481J Presserfoot Lever w/490

A358 23007 Washer, 13/64 x 7/16 x 1/32 481H Presserfoot Lever

A359 23267 Spring Pin, 1/16 x 3/8 481F Screw, 1/4 x 3/8 Shoulder

A360 23211A Square Shaft,

5"-

8"

490 Screw, 5/16 x 3/8 Set

23211B Square Shaft,

9"

1256 Spring Pin, 3/32 x 1/2

~-~

23211C Square Shaft,

11"

23292 Ball,

5/8

23211 D Square Shaft,

14"

Always

Give

Machine

SERIAL

NUMBER

When

Ordering

Parts.

Order

By

PART

NUMBER-

Not

Key

Number

7