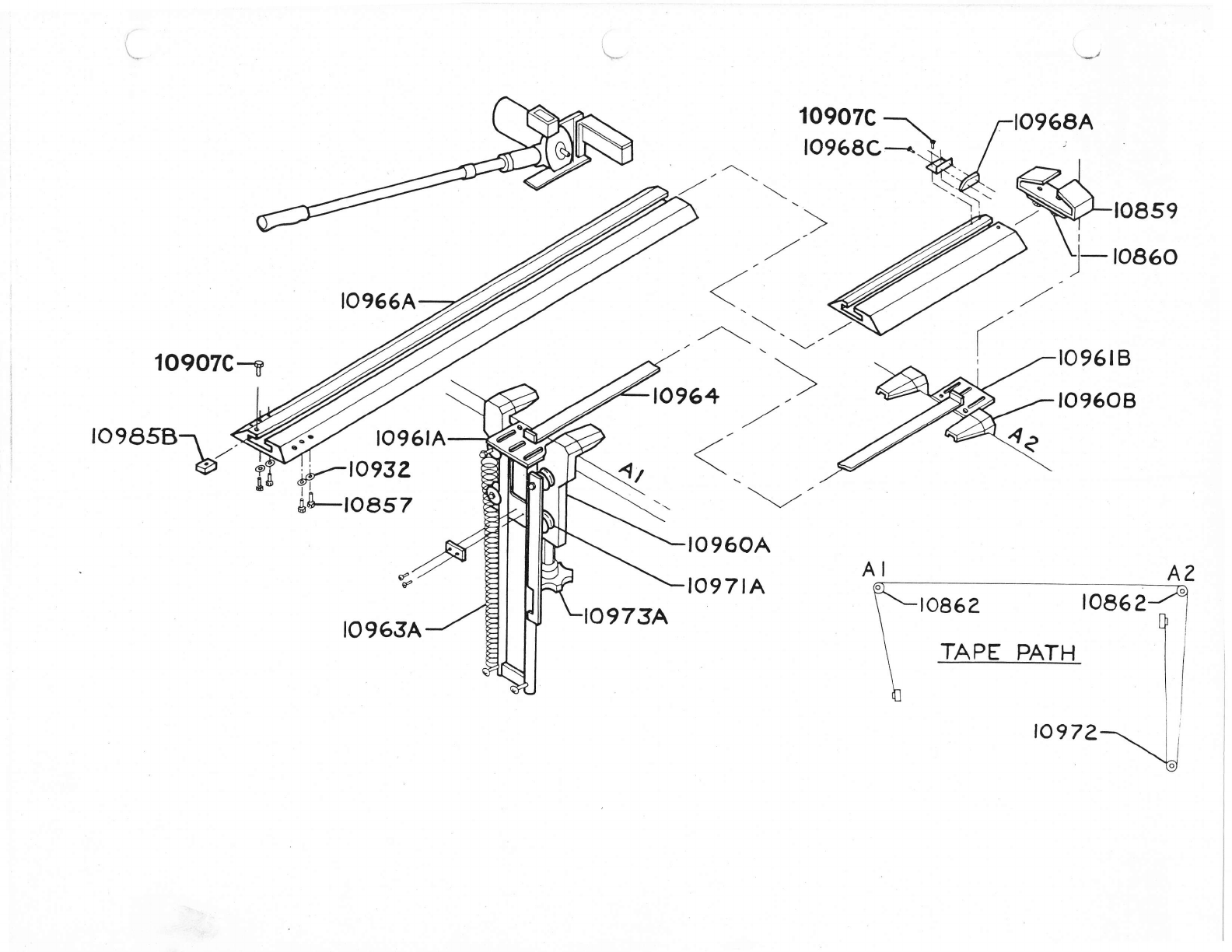

K-].05 ASSEMBLY TNSTRUCTTONS

Operator stands on side A1 of table.

Opposite side is side A2.

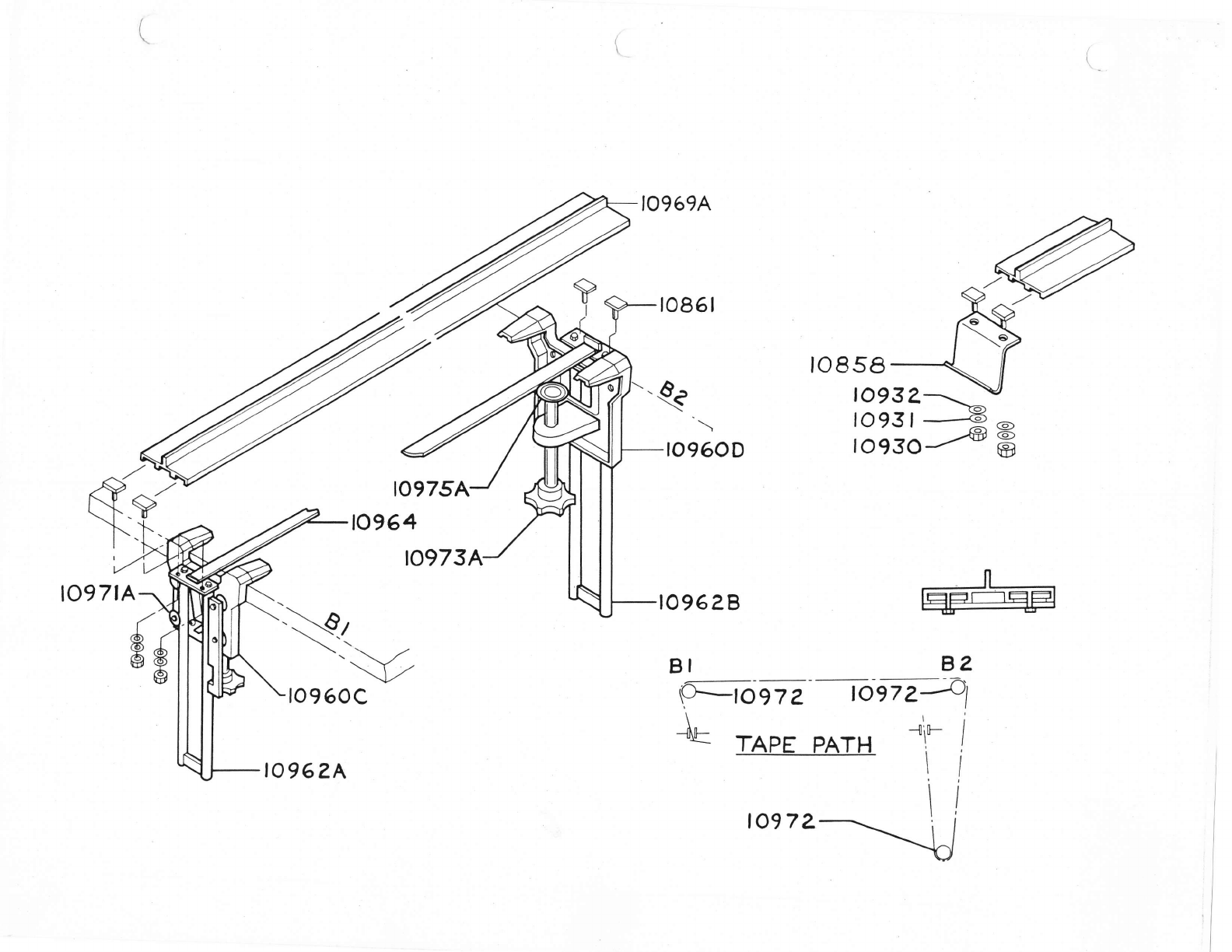

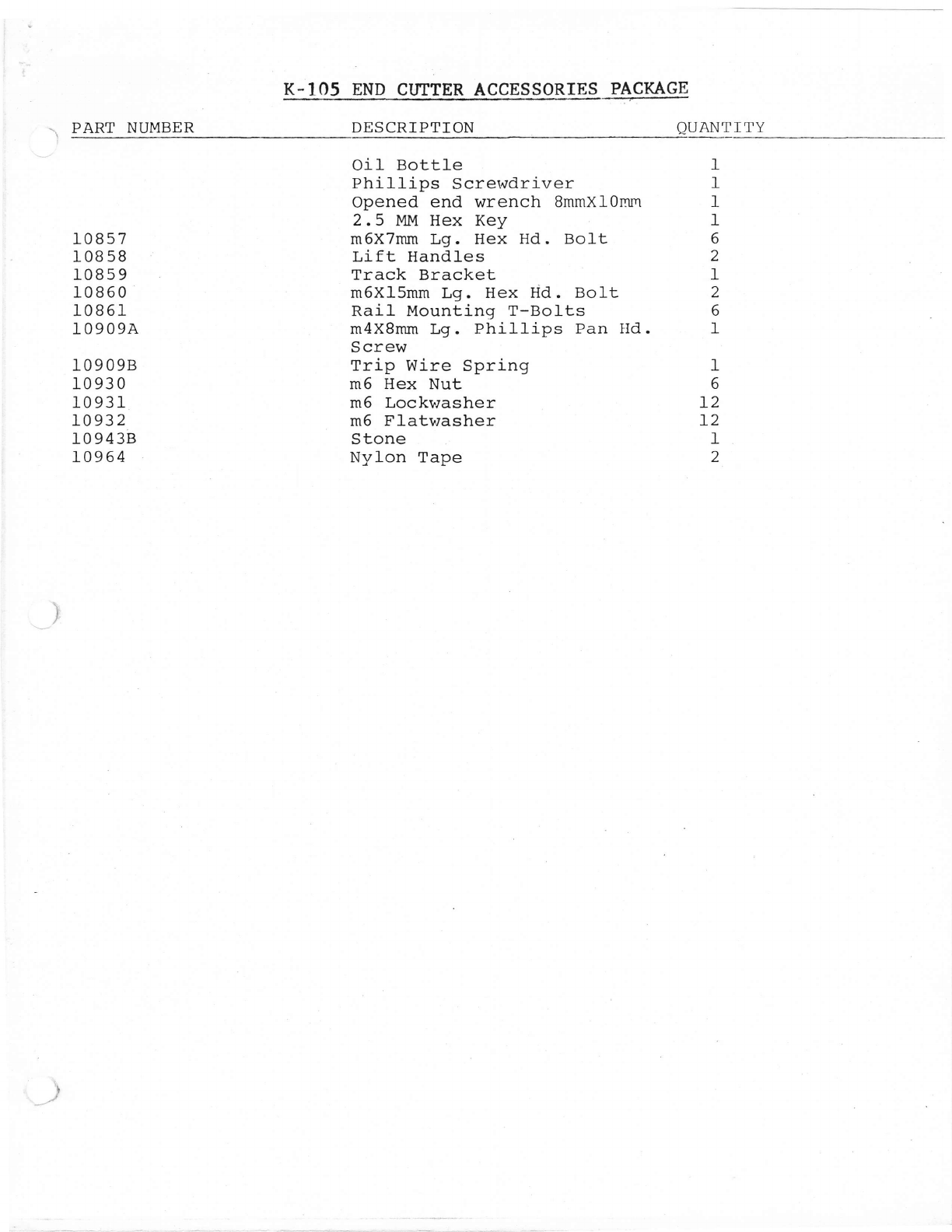

1. Clamp two supports A1. (10960A) and A2 (109608) to table

opposite each other.

Instafl nylon tape (10964). Pass one end of tape through

top roller (10862) of track base Al (10961A) and under tape clamp

on support. Tighten tape c1amp. Pull- tape across tabte, over

top roller on track base A2 (10961A), around lower rolfer (IOg72)

and up to tape cIamp. Tighten tape clamp.

Attach cutter track (10966A) to A1 base with bolts (10857), flat-

washers (10932) , and lockwashers (1093f) . Attach cutter track to

A2 base with bracket (10859). Bracket sl_ides over track and base.

It is then l-ocked from underneath base A2 with (2) bolts (10860).

Switch release (10968A) should be at A2 end. To operate ply

counter install trip wire spring onto cutter track.*

Remove from cutter track (2) phillips pan head screws (10907C)

at A1 side. Remove shock absorber clamp (10985c) and shock

absorber (109858). rnsert standard of cutter into groove in

track with machine handle facing A1 side. Replace shock absorber,

shock absorber clamp and screws.

3.

4.

7.

B.

Clamp two supports 81 (10960C)

each other. 81 support should and 82 (10960D) to tabl_e opposite

be on same side as Al_.

rnstal-l nylon tape (10964). pass one end of tape throuqh top

roller (l-0972) of track base Bl (10962A) and under tape clarnf on

support. Tighten tape clamp. pull tape across table, over top

roll-er on track base 82 (10962A), around lower rol]er (rogj2) and

up to tape clamp. Tighten tape clamp,

rnsert end rail mounting T-bolts (1086r) into channels of encl

rail (10969A) . Fasten end rail with mounting T-bo]ts in channels

thru lifting handle onto end rail base with nuts (10930), ft.rt-

washers (10932) and lockwashers (10931). Repeat for other side.

Both sides of cutter track and end rail should raise equally.

Adjust tension on tape if necessary.

Cutter may be mounted in "PUSH" position if desired. Machine is

off at side Al and operator pushes machine handle to start moLor

and cut. To install in this position, mount track (10966A) with

switch release at A1 end.