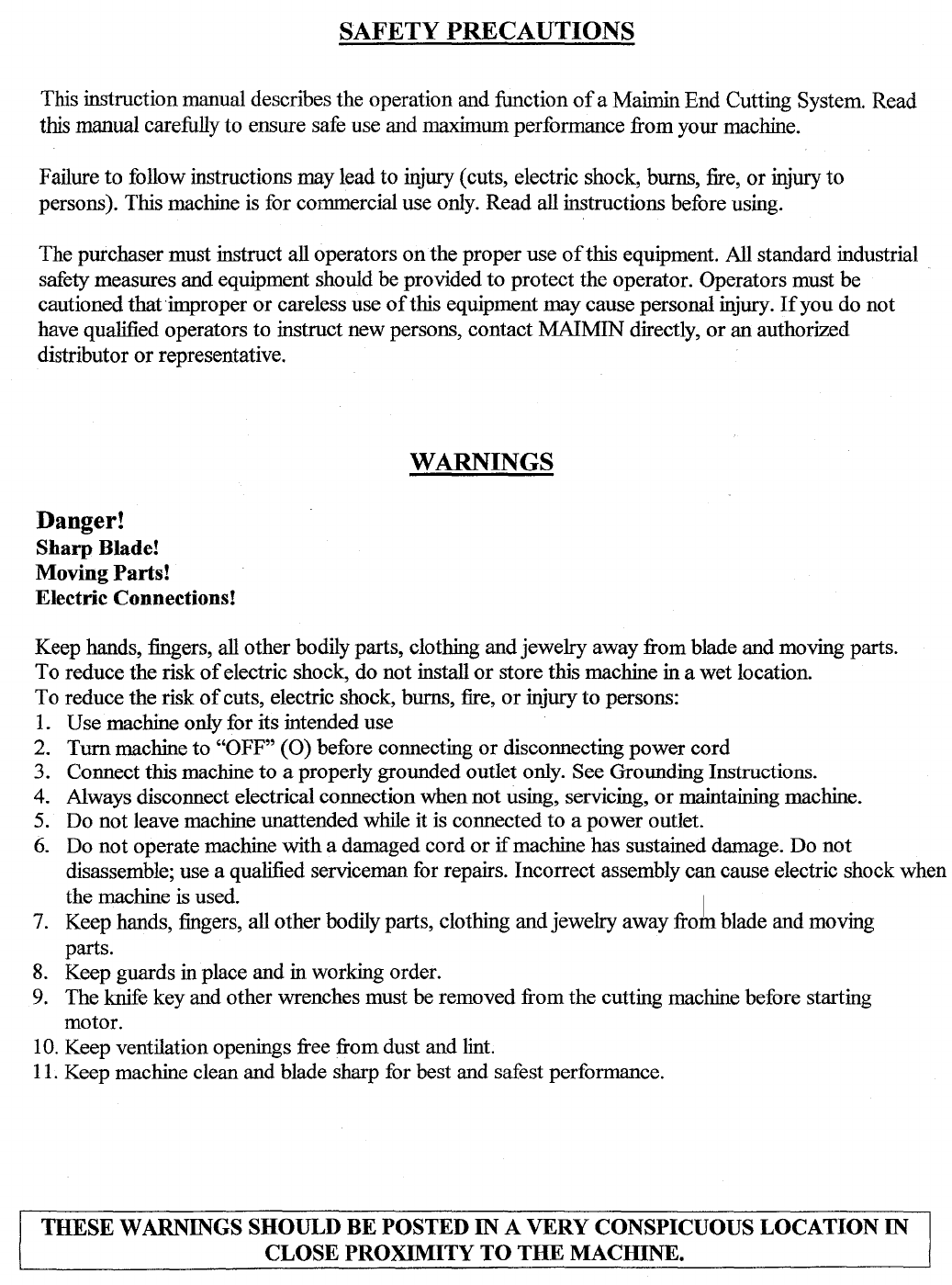

SAFETY PRECAUTIONS

This instruction manual describes the operation and function

of

a Maimin End Cutting System. Read

this manual carefully to ensure safe use and maximum performance from your machine.

Failure to follow instructions may lead to injury (cuts, electric shock, burns, fire,

or

injury

to

persons). This machine is for commercial use only. Read all instructions before using.

The purchaser must instruct all operators

on

the proper use

of

this equipment. All standard industrial

safety measures and equipment should be provided

to

protect the operator. Operators must be

cautioned that·improper

or

careless use

of

this equipment may cause personal injury.

If

you do not

have qualified operators to instruct new persons, contact MAIMIN directly,

or

an authorized

distributor

or

representative.

Danger!

Sharp Blade!

Moving Parts!

Electric Connections!

WARNINGS

Keep hands, fingers, all other bodily parts, clothing andjewelry away from blade and moving parts.

To reduce the risk

of

electric shock, do not install

or

store this machine in a wet location.

To reduce the risk

of

cuts, electric shock, burns, fire,

or

injury

to

persons:

1.

Use machine onlyfor its intended use

2. Turnmachine to "OFF"

(0)

before connecting

or

disconnecting power cord

3. Connect this machine to a properly grounded outlet only. See Grounding Instructions.

4. Always disconnect electrical connectionwhennot using, servicing,

or

maintaining machine.

5. Do not leave machine unattended while it is connected to a power outlet.

6.

Do

not

operate machine with a damaged cord

or

if

machine has sustained damage. Do

not

disassemble; use a qualified serviceman for repairs. Incorrect assembly can cause electric shock when

the machine

is

used. 1

7.

Keep hands, fingers, all other bodily parts, clothing andjewelry away from blade and moving

parts.

8.

Keep guards in place and in working order.

9.

The knife key and other wrenches must be removed from the cutting machine before starting

motor.

10.

Keep ventilation openings free from dust and lint.

11.

Keep machine clean and blade sharp for best and safest performance.

THESE WARNINGS SHOULD BE POSTED

IN

A VERY CONSPICUOUS LOCATION IN

CLOSE PROXIMITY

TO

THE

MACHINE.

From the library of: Superior Sewing Machine & Supply LLC