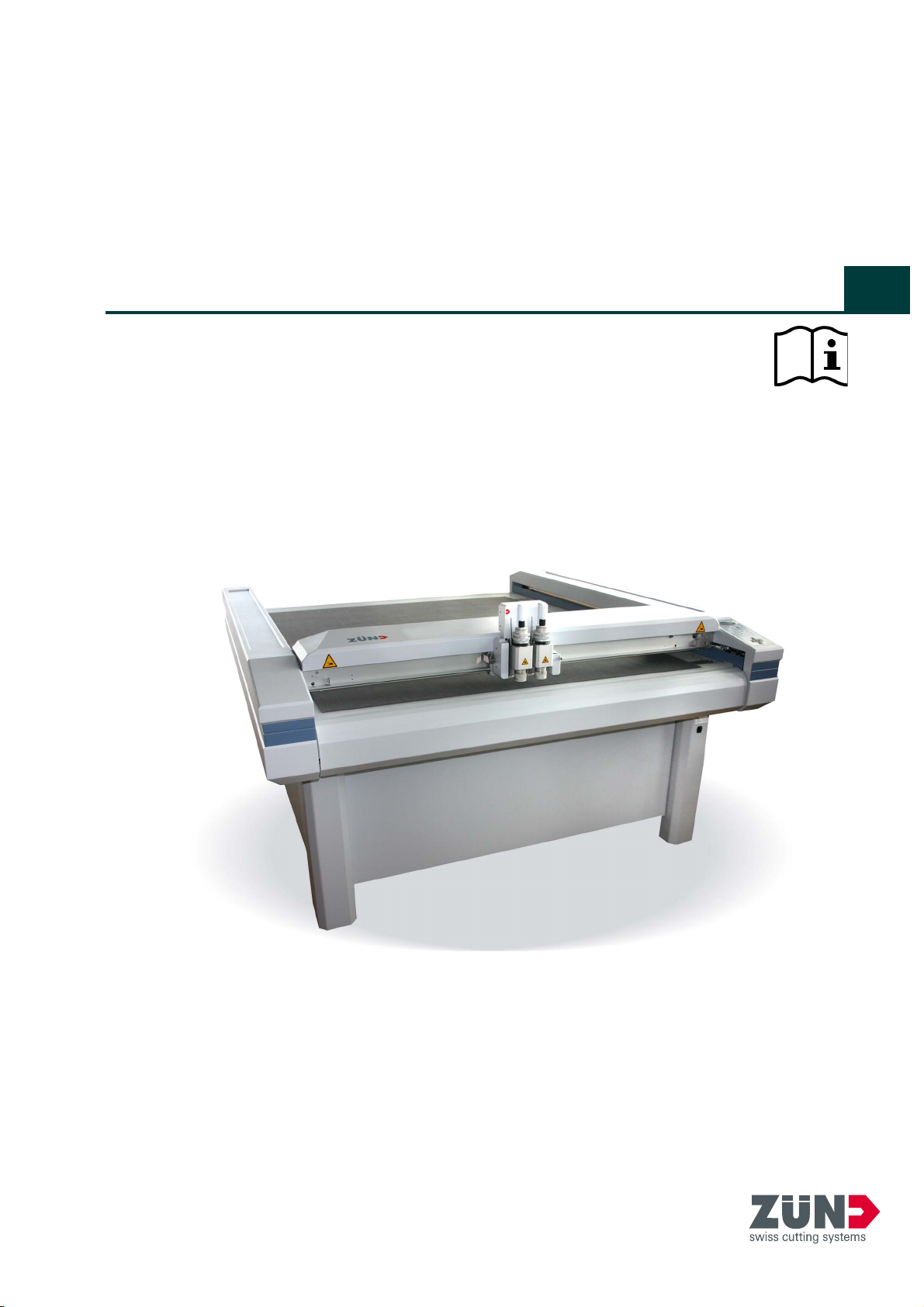

PN series frame version

0-1

110002,001,11-2009, jmu

0

Contents

1Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Using the documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Structure of the operating manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.2 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Points to note when reading this operating manual . . . . . . . . . . . . . . . . . . 4

1.4 Care of the documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Current status of documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 Standardisation, tests, marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6.1 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6.2 CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.7 Legal notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.8 Troubleshooting, hints and tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.9 Documented cutter models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.10 Publishing details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.2 Product identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.3 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.4 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.5 Layout and function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.6 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.7 Technical information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.7.1 Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7.2 Mains connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7.3 Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7.4 Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7.5 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7.6 Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3.2 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.3 Examples of improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.4 Hazard warnings, important instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.4.1 Explanation of the hazard warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.4.2 Structure of the hazard warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.5 Areas of responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.6 Personnel requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.7 Rules and safety at work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.8 Procedure in case of malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.9 Danger areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.9.1 Danger areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.9.2 Danger area during processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.9.3 Danger area during initialisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.10 Working and traffic area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.11 Safety signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.11.1 Responsibility of the operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11